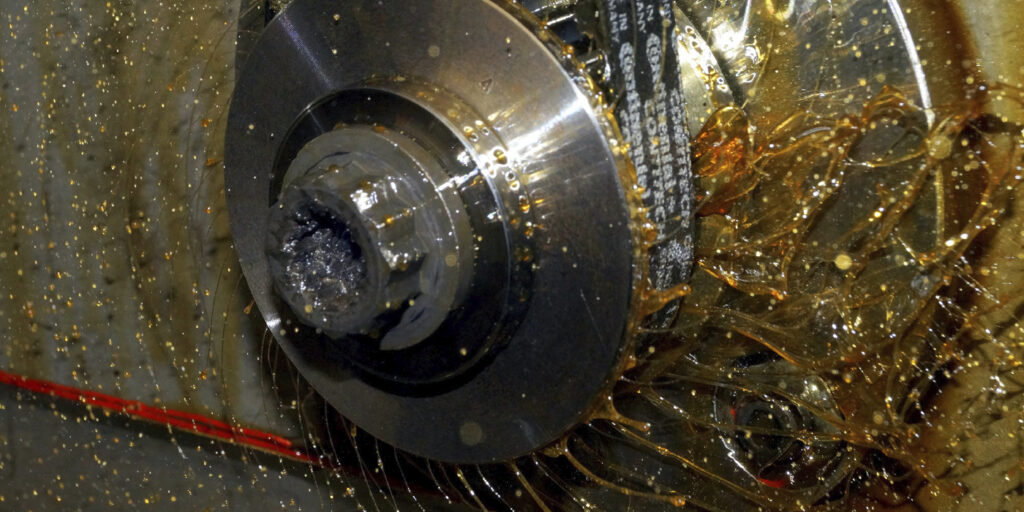

Since the adoption of timing belts by auto manufacturers began in the early 1970s, it has been pretty well beaten into our heads that oil and timing belts do not play well together. Oil contamination of the belt drive has been a death sentence, due to the rubber and fiber construction of the traditional timing belt. Oil attacked the rubber as well as the raw edge of the belt with its exposed fibers, weakening the belt until it delaminated (losing its teeth), or the belt snapped.

I was therefore a little bit surprised when I heard about the “belt-in-oil” (BIO) timing drives that are being used by well-known manufacturers in the European market, and available from a few equally well-known aftermarket suppliers. I was even more surprised to discover that this odd arrangement is already available here in the U.S.

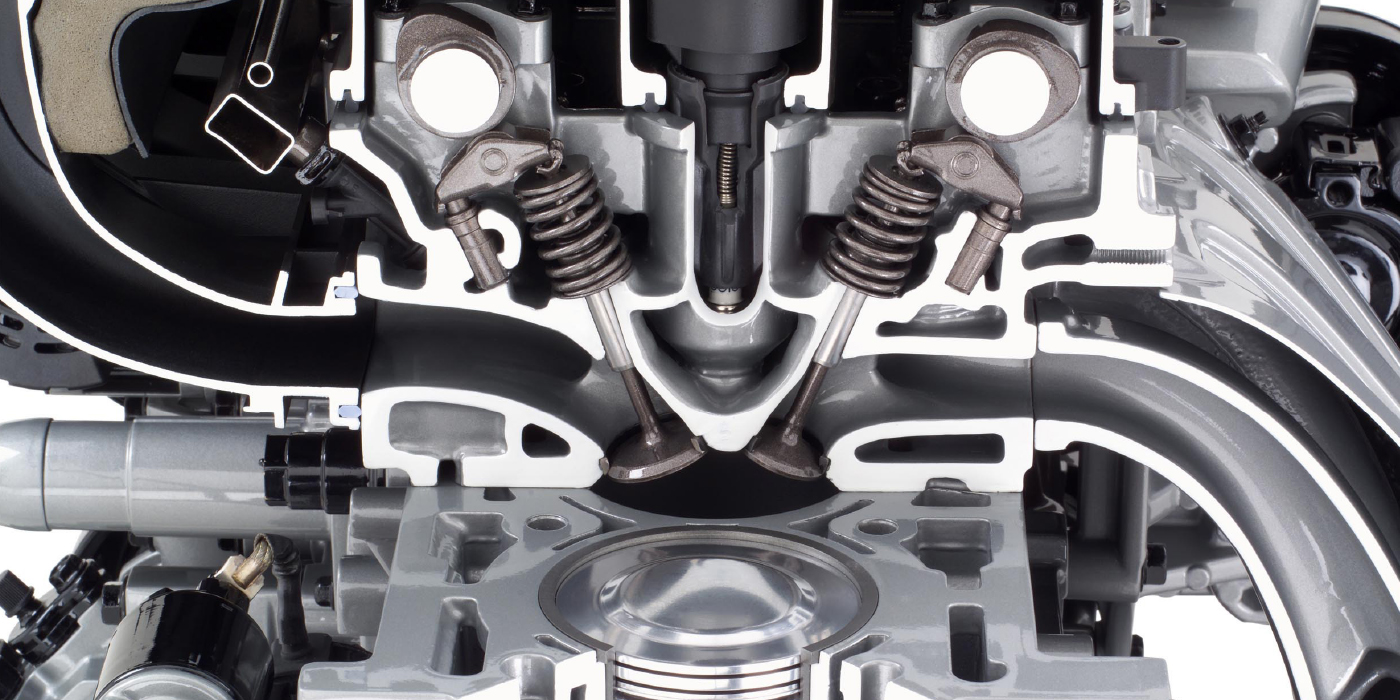

Now, performance enthusiasts may have some experience with “wet belt” timing systems as an upgrade for the small-block Chevy, but these “new” BIO systems are OEM designs, used for oil pump drives as well as for camshaft timing drives. As a performance upgrade, belt drives have a couple of advantages. Since a timing belt is lighter than a chain, and it can absorb and isolate crankshaft harmonics from the valvetrain, a belt is quieter and doesn’t rob additional power from the engine.

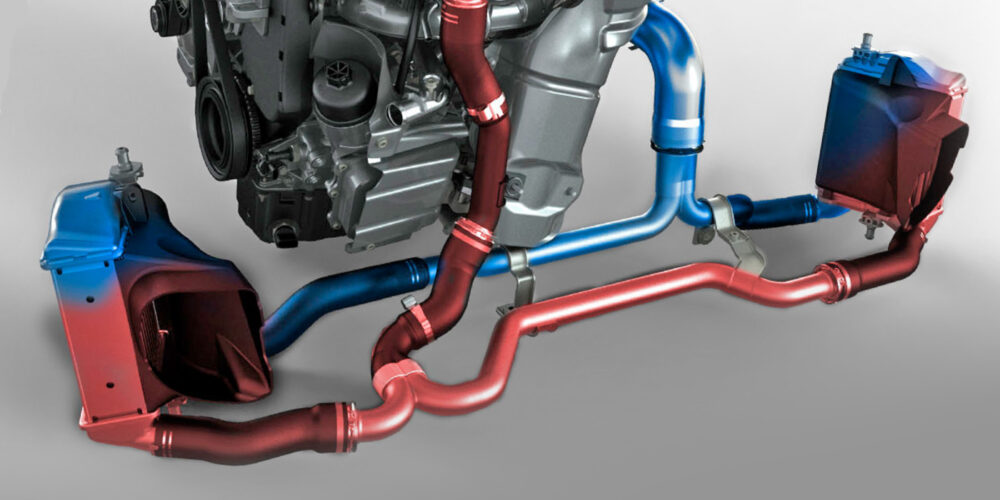

“Fuel efficiency,” “reduced emissions,” “noise, vibration, harshness” (NVH) and “compact design” are all popular catch phrases in the auto industry, and these also are the driving forces behind belt-in-oil technology. By designing a light, quiet and compact belt drive, manufacturers hope to increase fuel efficiency while reducing emissions and NVH, and package it all into ever-smaller engine designs. Belt-in-oil manufacturers claim that “wet belts” offer up to a 30 percent reduction in friction loss as compared to chains or dry belts. This reduces emissions and can increase fuel economy by a little more than 1 percent.

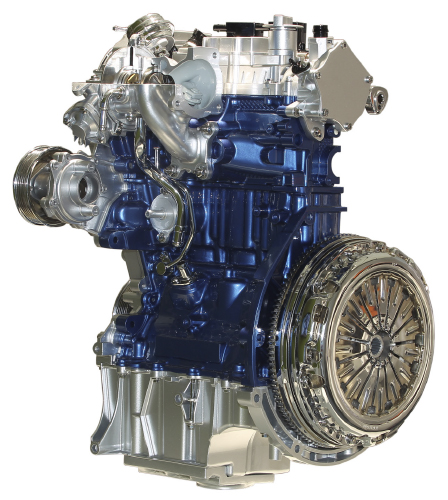

Due to the improved materials used in the BIO drives, these belts are more temperature-resistant, less prone to stretching than conventional dry belts and have a life expectancy of up to 150,000 miles. The first automotive BIO system was introduced in 2008, hidden inside the European-market 1.8L Ford diesel. Volkswagen soon followed with its EA211 and EA288 engine families of three- and four-cylinder gas and diesel variants. Here in the United States, belt-in-oil applications are a bit more limited, in the form of the 1.0L Ford EcoBoost gasoline engine, and (if you like to think outside the box) Honda offers the GC and GCV series of small engines featuring an internal oil-bath timing belt.

As emissions and fuel economy standards become more and more difficult for manufacturers to meet, unique technologies like these will drive the future of the industry. The globalization of our industry also means that technologies introduced in other parts of the world may soon come to our shores, too. Lightweight, compact components with extended service intervals are becoming the “new normal.” But, don’t worry that these claims of “lifetime” or “high-mileage” wet belts mean that the aftermarket will lose out on future parts sales. The European aftermarket already offers BIO timing kits, and, from what I’ve seen so far, they’re becoming a rather popular category already.