A code P0299 for lower- than-normal boost can be one of the most challenging DTCs to resolve. You might think it is a code for a leak, but it could be more than a leak. The criteria for setting the code is very basic. The engine management system is looking at the desired boost pressure and the actual boost pressure, if the actual and desired do not match for the conditions.

Different vehicles might have other criteria for setting a P0299 DTC. One vehicle may specify that the lower boost levels must occur for more than three seconds at a given throttle angle. Most require multiple incidents over one or two key cycles. If you have a scan tool, you can access the freeze-frame information when code P0299 was set.

Many components and conditions could cause a P0299, such as a restricted air filter or blocked catalytic converter. Why? If the engine can’t ingest or expel air, it can’t create boost.

One of the more common causes of a P0299 is a stuck or leaking wastegate. If exhaust gases are bypassing the turbine, the compressor can’t spool up. The wastegate’s shaft can become frozen in the exhaust housing. Also, the housing can crack where the flap seals against the seat and cause a leak.

On the control side, it is possible for a solenoid to fail in the open position and cause the actuator for the wastegate to stay open. A leaking wastegate can also occur if carbon deposits build up around the wastegate flap. Carbon deposits are caused by oil, which could come from leaking turbocharger shaft seals. But, oil could also be coming from the PCV system. If the PCV system is not functioning correctly, it can cause the engine to ingest large volumes of oil droplets and crankcase vapors.

Diverter valves can fail to seal and cause a P0299 code. Most of these leaks are caused by the seals on the sides of the valve’s piston in the compressor housing. The greater the boost pressure, the greater the leak.

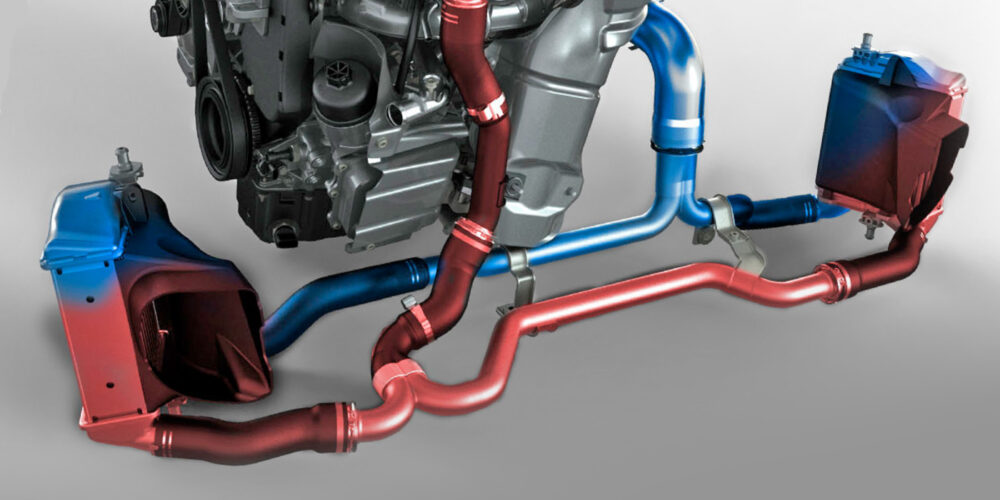

Leaks in the plumbing and intercooler can cause a P0299 code. These leaks will often occur at the couplings between charge pipes. Finding the leaks can be difficult due to the packaging of the intercooler behind a bumper. A smoke machine can help find the leaks, but you may need to upgrade it. Most smoke machines are designed to test EVAP systems and can’t generate enough pressure to cause a coupling or cracked intercooler to leak.