There are more than seven million hybrid vehicles on the roads in the U.S. The one thing they all have in common is that they will need maintenance. Even EV vehicles will require maintenance and potentially a certain amount of service at some point.

Many hybrid vehicles will have more maintenance items than a conventional internal combustion-only vehicle due to the hybrid drivetrain. These are opportunities your shop can’t pass up just because the car or SUV has a hybrid badge on the back.

Before You Start

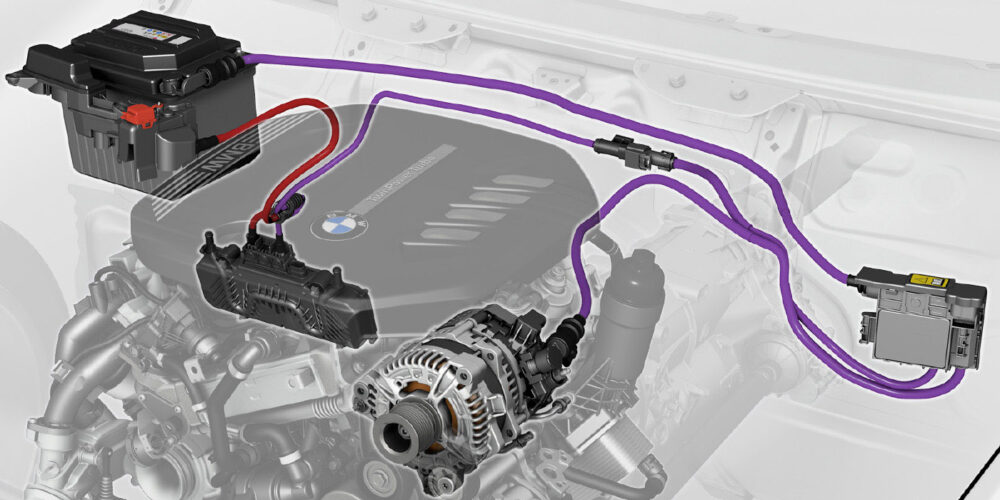

Chances are that 90 percent of the repairs on hybrid vehicles will not involve the high-voltage system. Most of the repair and maintenance items will involve mechanical systems and the 12-volt battery. You need to pay attention to what systems are energized when performing a repair.

The first item to pay attention to is the key. Chances are, a hybrid will have a proximity key. When these keys are around the vehicle, they can cause systems to activate. When the driver hits the “start” button, it can perform several actions. On most modern hybrids, the internal combustion engine will not start when the button is depressed. On some hybrids, the engine may start to charge the battery or heat the coolant to warm the passenger compartment or warm the catalyst.

If you are going to take chances and not look at the service information, you should remove the keys from the bay or place them in a special box that can block radio signals. The alternative is to use a scan tool to activate and disable specific modes. A scan tool can even start the engine so you can perform diagnostics or just check the level of the oil.

If you do need to disconnect the high-voltage system, most vehicles will have a service plug that disconnects the high-voltage battery from the system. Before you remove the plug, check the service information. Procedures differ depending on the manufacturer. Some may require the 12-volt battery to be disconnected or that you also use a scan tool to de-energize the system. Don’t take chances. Never assume that one model year of a hybrid is the same as the next. Many manufacturers made sweeping changes due to improvements in software and hardware.

When the high-voltage battery is reconnected, it might require a scan tool or specific procedures to restart the system.

Cooling Systems

Most hybrids have a separate cooling system for the inverter and electric motors/generators in the transmission case. These typically have their own electric pump, heat exchanger and special coolant. On most hybrids, there are two coolant reservoirs under the hood.

Always make sure the fluid is at the correct level for both systems. Most manufacturers recommend flushing and filling the system when the engine’s cooling system is serviced. Most vehicles will use the same coolant for both the engine and hybrid system.

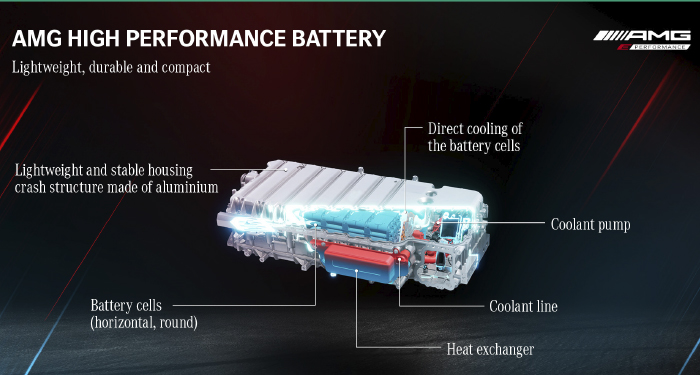

The hybrid battery system can generate a lot of heat. The traction motor will generate heat in operation. The inverter creates heat as DC power is converted into AC power. Also, the battery pack can generate heat as it is charged. The coolant of these systems can be very specific and will need to be non-conductive. Most systems will have at least two electric water pumps to move the coolant and heat around. The flow of coolant will be regulated by valves that will cool that motor, high-voltage battery and inverter at different rates. If you are replacing the coolant, you need a scan tool to open and close the valves to fill and bleed the system.

Some hybrids will have a thermos of coolant connected to the engine’s cooling system. This insulated vessel keeps the coolant inside warm. Some systems can keep the coolant at 180 degrees for three days inside the thermos. When the engine is started, the warm coolant is released into the cooling circuit using a valve and maybe a pump. To remove, flush or bleed the coolant that will require a scan tool to operate the valve and pump. Not being able to remove the old coolant from the thermos can leave a large volume of contaminated coolant in the system.

Engine Oil

Oil changes may not be needed as often with a hybrid because the engine runs less during low speeds and stop-and-go driving, but the oil still needs to be changed (refer to the vehicle manufacturers’ oil change interval recommendations). Starting an engine is the greatest cause of wear on any engine, and hybrids regularly shut down and restart the engine more than a conventional vehicle.

Plug-in hybrids can be the hardest on oil. Some trips might use the engine for only very short periods. Over repeated trips, condensation can cause moisture to build up in the oil. The condition might get so bad that the oil will have a milky appearance on the dipstick. You might be convinced the head gasket is leaking, but the cooling system will hold pressure. The only fix for this problem is updated calibrations for the engine and hybrid system. These tweaks to the operating system may allow the engine to run and get up to operating temperatures to evaporate the water from the oil.

Always use premium engine oils for these vehicles. Some late-model hybrids call for 0W-20 or 0W-16 weight motor oil. Not using the correct weight will damage the engine.

Brake Fluid

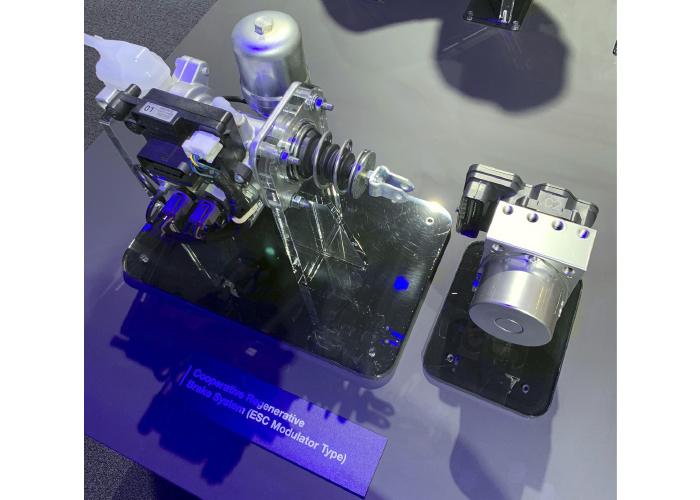

The brake system of a hybrid may have multiple components to perform regenerative braking. Regenerative braking is the hybrid’s first choice for braking to help charge the battery.

On most hybrids, the pressure generated for the calipers is not, under normal conditions, the direct result of the driver’s foot pedal efforts. The pedal-generated pressure is used to stimulate a pressure sensor in the system that makes up the brake request. Normally, the fluid pressure for the wheel hydraulics is generated by the pump and/or accumulator in the ABS HCU or a stroke simulator, and is regulated by the tandem efforts of the ABS and the PCM’s logic. The brake pedal acts more as an interface for the ABS module than as a request for braking.

If you are replacing and bleeding the brake fluid, a pressure bleeder and flare wrenches will not work. You need a scan tool to complete the procedure to open and shut valves in the HCU and pedal simulator to remove air pockets.

Some newer hybrids may specify DOT 4+ or DOT 4 Low Viscosity. These fluids have a lower viscosity rating compared to DOT 3 and regular DOT 4. These fluids are designed to work with high-pressure pumps and valves found in some hybrid brake systems.

Transmission Fluids

In all hybrid automatic transmissions, transmission fluid does not come in contact with the motor drives. On the Prius, the CVT part of the transmission is sandwiched between the two motors/generators. In the first-generation Prius, there were rare reports of the transmission fluid leaking into the electric motor case and damaging insulation. Any leak or loss of fluid should be taken seriously.

Some models will require a CVT-specific transmission fluid, while others will require a specific grade of fluid that could be compatible with conventional transmission fluid specifications.

Pay attention to the Mercon and manufacturer grades. For example, Mercon V is not the same as Mercon LV, which has a different viscosity. Check the container or ask your supplier if a fluid is compatible before you put it in the transmission. Never take specifications for granted — some Ford Fusion hybrids call for a Toyota/Aisin grade of transmission fluid.

Power Steering

The bad news is most hybrids do not have conventional hydraulically assisted power steering due to the requirement that the system needs to operate with the engine off. The GM full-sized pickup and SUV two-mode hybrids use 42 volts from the battery packs to power the rack.

Air Conditioning

Some hybrid vehicles use air conditioning compressors that are operated by an electric motor instead of a drive belt. The motor’s insulated windings are immersed in the compressor’s lubricating oil. The oils used in these compressors have high dielectric (non-conductive) properties.

If a different type of oil somehow makes its way into one of these compressors, and if the insulation on the windings is damaged or compromised, a variety of problems may occur.

The greatest risk is that the oil may conduct high voltage to the compressor case or connected components. A person may receive an electric shock if they touch the compressor, engine, etc., and an appropriate ground.