Airtex offers the following Tech Tip to assist technicians in performing a fuel system voltage drop test.

Fuel System Voltage Drop Test

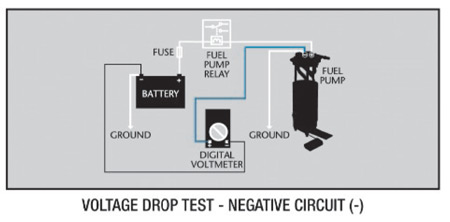

1. Address the negative side of the circuit first, then the positive side.

1. Address the negative side of the circuit first, then the positive side.

2. Connect one digital voltmeter test lead to the negative battery terminal and the other to the negative terminal at the fuel pump.

3. The fuel pump circuit must be energized to properly test. Energize the fuel pump relay and power the fuel pump circuit (see NOTE below).

4. If the negative circuit is in good condition, the voltage drop measured should be 0.5v DC or less. Larger voltage drop readings indicate a problem. Damaged or corroded vehicle wiring or harness connectors are likely sources of the problem.

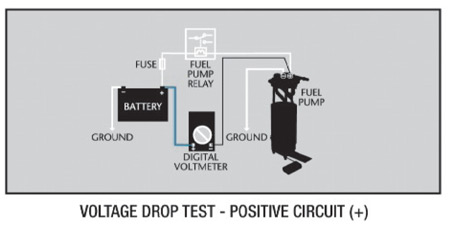

5. Repeat the voltage drop test on the positive side of the circuit. Connect one digital voltmeter probe to the positive terminal on the battery and the other to the positive fuel pump terminal.

5. Repeat the voltage drop test on the positive side of the circuit. Connect one digital voltmeter probe to the positive terminal on the battery and the other to the positive fuel pump terminal.

6. Energize the fuel pump relay and power the fuel pump circuit (see NOTE below).

7. As with the ground circuit, voltage drop readings larger than 0.5v DC indicate system wiring or connector issues.

NOTE: The majority of fuel pumps run for only a few seconds once the relay is energized (only long enough to prime the system) until an RPM signal is generated.

For information on products offered by Airtex or to view additional Tech Tips, visit www.airtexproducts.com.