Bosch has announced the launch of a new complete line of Bosch Workshop Oil Filters targeted to the traditional automotive repair market in the U.S. and Canada.

“Bosch is offering a new dedicated line of spin-on oil filters and cartridge filters for the installer market,” said Chuck Kerrigan, director of marketing for Filtration Americas, a business unit of Robert Bosch LLC. “And, by utilizing the familiar red-and-yellow packaging that Bosch has traditionally used for this segment, this new oil filter line carries the message of Bosch quality and reliability.”

Bosch offers oil, cabin air and fuel filters to the North American aftermarket.

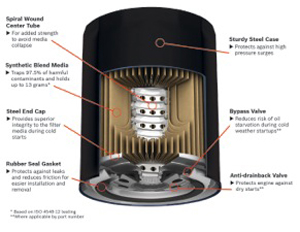

Ninety-seven Bosch Workshop Oil Filters provide a combined 98 percent coverage for domestic, Asian and European vehicles in operation (VIO) in North America, the company says. At an efficiency rate of approximately 97.5 percent in removing dirt and a capacity to hold 13 grams of dirt, these filters help a car’s engine oil to perform at its best for thousands of miles, Kerrigan said. To help visualize this, Bosch notes that 13 grams of dirt is the equivalent of 31 standard size paper clips.

By screening out more harmful contaminants, the new line of Bosch oil filters provide the car’s engine a high level of protection against dust and dirt, thereby ensuring a continued supply of clean oil for lasting performance, according to Bosch.

“All Bosch Premium Oil Filters have a more sophisticated construction, which provides a tight seal for a leak-free installation, and can still be easily removed,” Kerrigan said.

He added, “In a tough economy when car owners would be delighted at the chance to get the most out of their vehicles without spending a large sum of money, these filters provide a repair shop – for the first time – the ability to offer the excellence of Bosch quality filtration at such a value.”