Because diesel engines produce a lot of soot and combustion byproducts that end up in the crankcase, good filtration is needed to protect the engine from these contaminants.

The oil filters on diesel engines are typically much larger and have a higher holding capacity than those on gasoline engines. Some truck applications have two separate oil filters: a full-flow filter and a bypass filter to help ensure good filtration under all operating conditions. Newer diesel oil filter designs often combine full-flow and bypass features into a single filter. Combination filters typically have a wrap-around pleated full-flow media inside with stacked disc bypass media at the top or bottom.

Full-flow filters (or the full-flow portion of a combination filter) typically trap debris 30 microns or larger, while bypass filters (or the bypass portion of a combination filter) capture contaminants down to 10 microns in size. Some combination filters can even trap particles as small as five microns. Smaller particles can actually cause more engine wear over time than larger particles.

Approximately 75% of the contaminants trapped by the oil filter are combustion byproducts (soot and sludge) rather than engine wear particles or dust or dirt from the outside environment.

The filter’s holding capacity (how much dirt it can hold), as well as its efficiency, are important because both determine how long the filter can last before it has to be changed. You want a filter with high efficiency (98% or higher) to trap as many contaminants as possible, but you also want a filter with the adequate capacity so it doesn’t plug up before it is changed. If the filter media becomes clogged to the point where the filter goes into bypass mode, the engine will be running on unfiltered oil.

Before an engine is started for the first time, the oil filter should be prefilled with oil to minimize the time it takes the engine to develop normal oil pressure. The filter should also be changed every time the oil is changed, not every other time to reduce the risk of filter clogging.

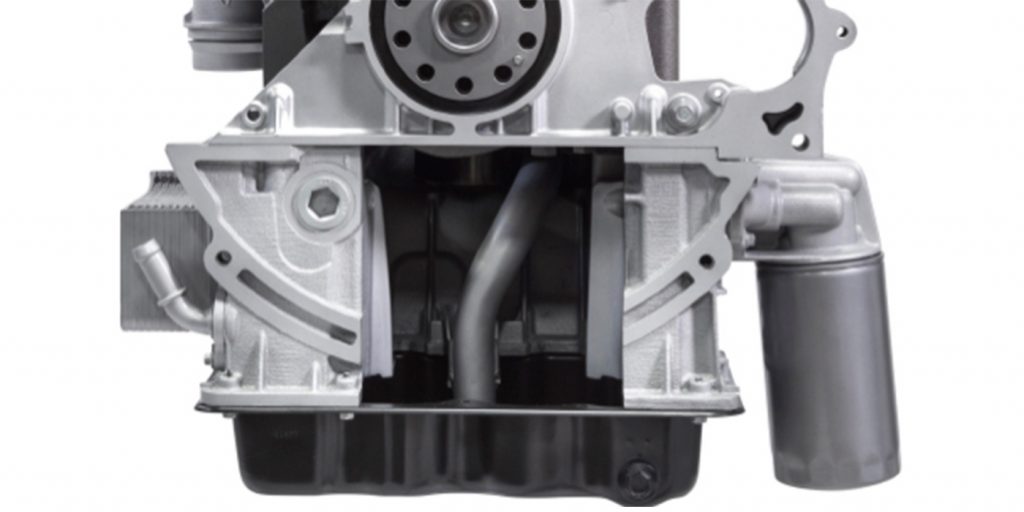

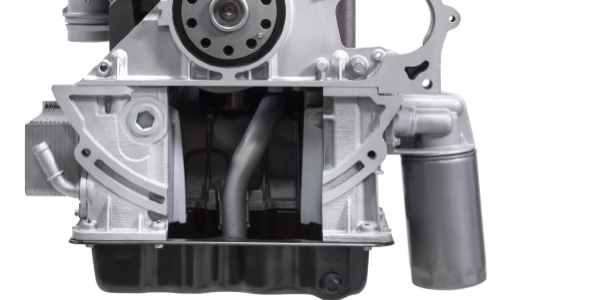

Another tip that can prevent engine warranty claims or problems down the road is if the engine has an external oil cooler, the lines and/or cooler should be inspected and cleaned to make sure there are no contaminants lurking inside that could cause problems. Any junk in the oil cooler can pass right through to the engine’s main oil gallery that feeds the main bearings, cam bearings and timing gears. That, of course, can be catastrophic.