Failure Points

Because the Quadrajet was a mass-produced carburetor, it suffered from a few failure points in its basic design. The most notable failure in a Quadrajet is the secondary metering rod well plugs leaking fuel into the intake manifold air stream. The symptoms of leaking well plugs are a rich idle air/fuel mixture or a rolling idle caused by a fuel drip into the intake air stream.

Early Quadrajets used brass well plugs that could be replaced with a more durable O-ringed aluminum plug. The well plugs on later Quadrajets were swaged into the main body and are better sealed with a hardening epoxy like JB Weld or a similar hardening epoxy compound. Inserting a lozenge-shaped neoprene plug into the cavity below the secondary metering wells can seal minor leaks. Both products are available from aftermarket suppliers. See Photo 1.

A second common failure is fuel-metering problem caused by over-tightening the Quadrajet’s two 5/16” diameter front mounting bolts. See Photo 2.

Over-tightening these bolts essentially warps the bowl cover, forcing it away from the main body casting. The problem can sometimes be remedied by suspending the cover between two steel bars mounted lengthwise in a hydraulic press and incrementally applying pressure until the cover comes back into tolerance. See Photo 3.

Fuel-saturated floats also may cause a Quadrajet to run rich or flood during normal operation. Float level can be measured by inserting a special Kent-Moore float level gauge into the bowl vent located just aft the choke valve. See  Photo 4.

Photo 4.

Measuring the distance from the top of the bowl vent to the float and then subtracting the dimension from the bowl vent to the cover gasket can also determine the float level. If a repair manual with adjustment specifications is available, refer to the float level specifications listed for the model number stamped vertically on the driver’s side of the carburetor main body or on a tab attached above the primary throttle shaft. Although most Quadrajet float levels are set at 3/8”, the specification can vary from 5/16” to 1/2”. Last, the metering rod piston can stick in its

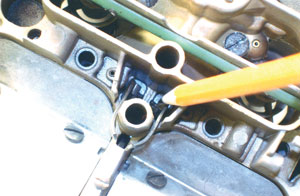

bore, causing a lean air/fuel condition. The metering rod travel can be checked by inserting a screwdriver or punch into the bowl vent hole in front of the choke valve to see if the metering piston spring returns the metering rods to a raised position with the engine off. Spraying some penetrating oil into the bowl vent and tapping on the metering rod hanger with a screwdriver or punch can often loosen the metering rods. See Photo 5.

bore, causing a lean air/fuel condition. The metering rod travel can be checked by inserting a screwdriver or punch into the bowl vent hole in front of the choke valve to see if the metering piston spring returns the metering rods to a raised position with the engine off. Spraying some penetrating oil into the bowl vent and tapping on the metering rod hanger with a screwdriver or punch can often loosen the metering rods. See Photo 5.

Quadrajet Adjustments

The Quadrajet has a number of critical adjustments that make it perform better. The initial adjustment for idle mixture screws on most Q-jets, for example, should be lightly seated and then  backed out three turns. Initial idle speed can be obtained by seating the primary throttle plates and then turning the idle speed screw in about two turns.

backed out three turns. Initial idle speed can be obtained by seating the primary throttle plates and then turning the idle speed screw in about two turns.

Primary jetting is most easily corrected by increasing the jet size in two-step increments. To remove the primary metering rods, lightly tap the metering rod hanger with a screwdriver handle. Spring pressure will pop the plastic retainer from the main body casting.

Before installing any Q-jet, make sure that the secondary throttle plates are seated and that the secondary throttle linkage is adjusted to specification. A tab on the primary throttle shaft actuates the secondary linkage. This tab determines the open position of the secondary plates. When the tab contacts the secondary linkage, the linkage pushes against the upper part of the secondary throttle shaft lever. At that point, the linkage should be located mid-point in the slot located below. See Photo 6.

On the topside, the secondary metering rod hanger should be adjusted to ideally achieve equal metering rod height and to allow both metering rods to touch the bottoms of their  respective wells. This adjustment is done incrementally to avoid binding the rods in their hanger and to avoid damaging the hanger itself. See Photo 7.

respective wells. This adjustment is done incrementally to avoid binding the rods in their hanger and to avoid damaging the hanger itself. See Photo 7.

Secondary air valve adjustment is critical to Quadrajet performance because correct secondary air/fuel metering requires a constant depression or vacuum in the secondary venturis. If a repair manual with adjustment specifications is available, begin with the applicable spec. If a specification is not available, preload the lock screw on the air valve spring preload adjustment. air valve spring adjustment one-half turn, then road test the vehicle. If the engine stumbles as it accelerates, increase the spring preload in one-half turn increments until the stumble disappears.

Last, always make sure that the choke valve lockout is allowing the secondary throttle plates to  open. Some Quadrajet models incorporate the lockout at the upper choke housing linkage while others locate the lockout at the secondary throttle shaft. In either case, the choke valve linkage keeps the air valves closed until the engine warms up. See Photo 8.

open. Some Quadrajet models incorporate the lockout at the upper choke housing linkage while others locate the lockout at the secondary throttle shaft. In either case, the choke valve linkage keeps the air valves closed until the engine warms up. See Photo 8.

Quadrajet Wrap-Up

When serviced correctly, the Quadrajet will prove to be a very responsive and economical carburetor to use for many street driving and racing applications. Although Quadrajet is very dependable, it pays to clean the external choke linkage and air bleeds with an aerosol cleaner. When changing the fuel filter, remember to replace the plastic gasket located on the end of the fuel inlet housing before reinstalling. Cross threading the inlet housing can be greatly reduced by cleaning and oiling the housing threads before installation. If the threads are seriously damaged, aftermarket kits can be used to replace the factory housing. In virtually all cases, a well-maintained late-model Quadrajet will maintain exhaust emissions within legal limits for collector and street rod vehicles while providing a full-bore performance experience.