Two factors govern all fuel injectors: pressure and time are used to calculate fuel flow into an engine. Pressure nor time can’t be used on their own to determine how much fuel the engine is using or to correct a wayward fuel trim number.

If a fuel pump (in-tank or high-pressure) can’t deliver enough pressure to the injector, the injector will have its open time increased to keep the fuel delivered by the injectors constant.

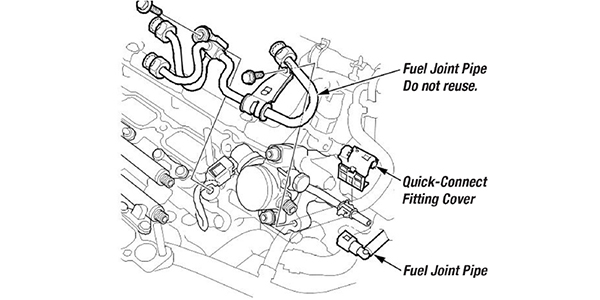

Gasoline direct injection (GDI) systems have another way to control pressure and the volume of fuel injected into the engine. This method controls not only pressure, but also the amount of fuel the pump compresses by spilling the fuel back into the low-pressure side.

Injectors

With more than 2,000 psi on the backside of an injector and combustion pressures on the other, more than 12 volts are needed to pulse the injector. Most direct-injection systems use a capacitor and voltage inverter to create voltages ranging from 40 to 100 volts, depending on the system. It’s possible to view the driver’s output using an induction clamp.

In most cases, if the ECM detects a problem, it will shut down the injector and driver for self-preservation. This is why observing a faulty injector on some systems may be impossible.

A direct injector is under much pressure so that leaks can happen. Some leaks may occur when the engine is resting, which will cause severe carbon buildup and a rich fuel reading.

When an injector is not firing, the affected cylinder becomes an air pump that forces large amounts of oxygen past the air/fuel ratio sensor. This can be viewed using a scope. The ECM can match the exhaust pulse to engine timing to determine the faulty cylinder.

Pressure Diagnostics

You will never find a Schrader valve or port to measure pressure on a direct fuel-injection system, even on the low side. If you could tap into the low side with an analog gauge, you would see pressures rapidly changing as the demands on the engine change. If you managed to splice an analog gauge into the high-side pump, the needle would be pegged. The splice would eventually leak, and the pressure coming out of the leak would be so great that the stream of fuel could cut through skin and bone. A fireball would then follow.

Direct injection pressure is measured with sensors, and the signals are used to determine pump speed and/or volume. So, you’ll need a scan tool to look at the pressures.

Most direct-injection systems use piezoresistive pressure sensors on the low side of the system. The silicone chip element generates a measurable electrical voltage when pressure is applied, increasing as the pressure increases. The ECM will turn the voltage into a calculated pressure with a ±2% accuracy. Measuring the values with a scope or meter will not yield any critical information, so always look at the value with a scan tool.

High-pressure sensors may use a metallic membrane on a resistance bridge. When pressure is applied, the bridge generates a change in resistance that will cause a change in the applied voltage.

The ECM is supposed to ensure the fuel pump supplies the correct pressure to the high-pressure pump. The ECM will pulse the low-pressure pump so that the correct pressure is generated. The system typically has a regulator and no return lines. Some systems even have integrated temperature sensors in the lines that calculate the fuel density so that the fuel trim can be tuned to the amount of energy in the fuel.

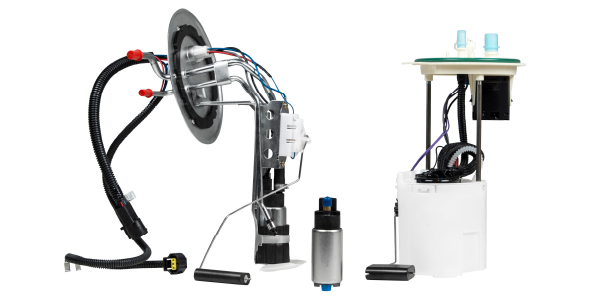

Low-Pressure/Supply Pumps

The ECM typically controls the low-pressure, in-tank pump with a pulse-width-modulated voltage signal. Its main responsibility is to provide the correct volume and pressure to the high-pressure pump. With this arrangement, there is no need for a return line.

The supply pump also can activate a limp-home pump if the high-pressure pump fails. Suppose the ECM detects a failure of the high-pressure pump with information from the high-pressure sensor. In that case, it will increase the output of the supply pump and the open injector time so that the engine can continue in a restricted power mode.

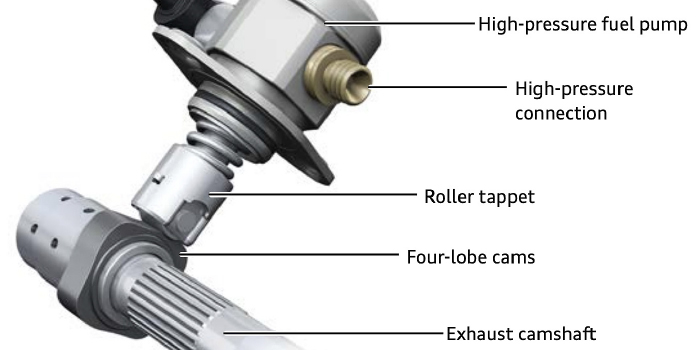

High-Pressure Pumps

The high-pressure pump on a direct-injection engine shares more in common with an ABS modulator pump than with a mechanically driven fuel pump.

Mechanical pumps use pressure and other engine-related information to determine output, which is controlled by an actuator, typically on the intake side of the high-pressure pump. When there is no voltage applied to the solenoid, it will revert to the low-pressure setting.

This pump is precision-machined to generate fuel pressure to the rail up to 2,500 psi. Fuel lubricates the internal parts of the pump, and if the fuel system is dry, the pump can be damaged. Debris from a failed filter or pump that makes its way to the high-pressure pump can also cause damage.

The main destroyer of high-pressure fuel pumps is a lack of oil changes. Wear between the camshaft lobes and the high-pressure pump prevents the fuel pump from generating enough piston movement. You should always examine the lobes on the camshaft before installing a new and very expensive high-pressure fuel pump. A lack-of-power complaint may improve, but it will never be completely corrected.

Diagnostic Margins

Engineers are building test cylinders with ruby quartz windows and are using the best high-speed cameras in the world to determine the best possible combustion event under different loads. They want to tune the perfect combustion event in which all the fuel is burned and the lowest amount of emissions makes it to the converter. This quest for perfection will become a diagnostic challenge for technicians in the years to come.

As engineers squeeze every bit of energy out of a droplet of fuel, every element in the system is operating on a razor’s edge of drivability problems. For example, a little bit of carbon on an intake valve can cause the air going into the combustion chamber to be turbulent and cause some of the fuel to condense and burn unevenly. Or, a small vacuum leak could cause unmetered air to enter the combustion chamber. Even a small change, like an air filter, may throw off the combustion.

Port fuel-injection motors compensated for these issues because they were expected to be somewhat inefficient. They had lower compression ratios and larger catalytic converters.

Now, every little item, from the condition of the spark plugs to the type of fuel used, is essential for a diagnosis. Worn parts and missed maintenance can cut into the diagnostic margins.

Veteran technicians can probably look at the datastream for timing, fuel trim and oxygen sensor values to determine the health of an engine or spot a problem before a vehicle turns on the check engine light. For a direct-injection engine, certain events you see will not match conventional wisdom. You will be amazed at how lean the system will run, how much ignition timing can change and when the injection event will happen.

Parts-swappers should stay away from direct fuel injection. The parts are expensive, and the majority of drivability problems can’t be solved with just one part or procedure. Technicians who look at the entire system and deduce where a problem originated will be way ahead of the game.