The new Nissan 2.0 L VC-Turbo (Variable Compression Turbo) offers similar performance figures to the 24-year-old 3.5 L V6 that it replaces, while providing 4-cylinder fuel economy. The first vehicle to receive the engine in the Nissan lineup will be the 2019 Altima SR. While it might be a few years before this engine is in your bays, the preparation and training needs to start now, not when you are stumped with a problem.

What sets the VC engine apart is the world’s first production variable-compression turbo engine. The technology was more than 20 years in development and is a breakthrough in combustion engine design as it continually adjusts its compression ratio to optimize power and fuel efficiency. It is projected to offer a double-digit percentage increase in fuel economy.

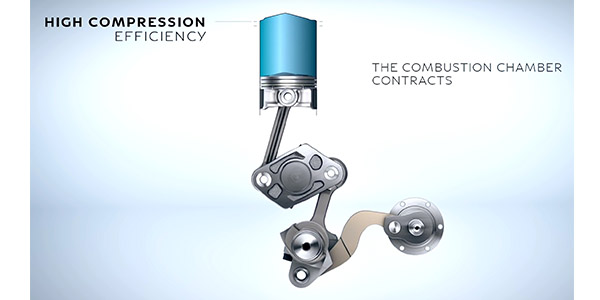

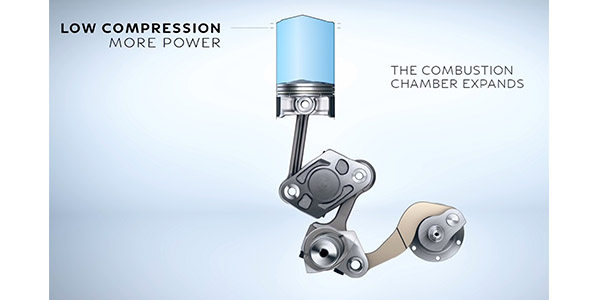

The VC-Turbo changes its compression ratio through an advanced multi-link system that continuously raises or lowers the pistons’ reach to alter the compression ratio for varying loads and engine speeds. A high compression ratio provides greater efficiency, but, in certain applications, it poses the risk of premature combustion (knocking). A low compression ratio allows for greater power and torque and prevents knocking.

As the angle of the multi-link arms changes, it adjusts the top-dead-center position of the pistons and the compression ratio with them. An eccentric control shaft changes the compression ratio of all the cylinders at the same time. As a result, the engine capacity varies between 1,997 cc (for a low 8:1 ratio) and 1,970 cc (for a high 14:1 ratio).