by Ed Sunkin, editor

by Ed Sunkin, editor

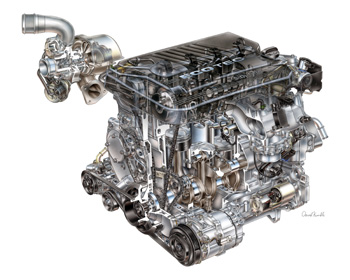

General Motors introduced its powerful Ecotec 2.0L direct injection turbo engine in the 2007 Saturn Sky Red Line at the New York International Auto Show. The engine was hailed by many that year for its capability to produce 260 hp and 260 lb.-ft. of torque, making it one of GM’s highest specific output engines ever, at 2.1 hp per cubic inch of displacement.

The Ecotec 2.0L Turbo was developed with the global resources of GM Powertrain in the U.S. and Europe, drawing on expertise from the naturally aspirated Ecotec 2.2L direct injection engine used in some European applications, and the 2.0L turbocharged engines already in production.

The Ecotec 2.0L Turbo was used in the Saturn Sky Red Line and the Pontiac Solstice GXP, and was GM’s first spark ignition, direct injection offering for North America.

Gasoline direct injection technology helped the Ecotec engine produce more power while maintaining the lower fuel consumption of a small displacement port-injected engine.

Variable valve timing and an intercooled, twin-scroll turbocharging system were used to optimize the Ecotec 2.0L Turbo engine’s performance.

Variable valve timing and an intercooled, twin-scroll turbocharging system were used to optimize the Ecotec 2.0L Turbo engine’s performance.

With direct injection, fuel is delivered directly to the combustion chamber to create a more complete burn of the air/fuel mixture. Less fuel is required to produce the equivalent horsepower (especially at normal cruising speeds) of a conventional port-injection combustion system.

GM engineers said that because direct injection technology works well with turbocharging and helps deliver a great balance of power and economy, the 2.0L Turbo produces the power expected of a V6, but in a smaller, more efficient package.

In November 2009, we featured the 3.5L ECOBoost — Ford Motor Co.’s first direct injection gasoline engine. This month, we take a look at GM’s first direct injection offering in North America, the 2.0L Ecotec that debuted in 2007.

Design Tech

The engine features a dual-scroll turbocharger while a lightweight turbine provides nearly instant power, and an air-to-air intercooling system bolsters the turbo’s performance by reducing inlet temperatures.

Dual cam phasing complements the turbocharging system by optimizing valve timing at lower rpm for best turbo response and quick engine torque build-up time.

The Ecotec 2.0L Turbo also uses a stronger, “Gen II” Ecotec engine block, which was developed with input from racing experience to support increased horsepower and torque. And, engineers made sure that the cylinder block bulkheads — the areas where the main bearing caps are attached — as well as the bore walls, were enlarged for strength.

The Ecotec 2.0L Turbo also uses a stronger, “Gen II” Ecotec engine block, which was developed with input from racing experience to support increased horsepower and torque. And, engineers made sure that the cylinder block bulkheads — the areas where the main bearing caps are attached — as well as the bore walls, were enlarged for strength.

GM designers said that other areas of the engine were enhanced to reinforce the structure, as well. In fact, components including the steel crankshaft, forged connecting rods and cast aluminum pistons were all high-strength components developed to enhance durability.

A deeper water jacket was created for added cooling capacity and improved cylinder bore roundness. You may notice that this design architecture is shared with the 2.4L (non-turbo) Ecotec engine that debuted in the Pontiac Solstice roadster.

Jet-Spray Oil Cooling

GM engineers said the engine’s oiling system delivers pressurized oil to continuously lubricate and cool the pistons, which reduces friction and noise. It’s also designed to ensure durability for the engine’s higher power levels. To enhance combustion, the piston tops feature a dish shape that deflects injected fuel toward the spark plugs.

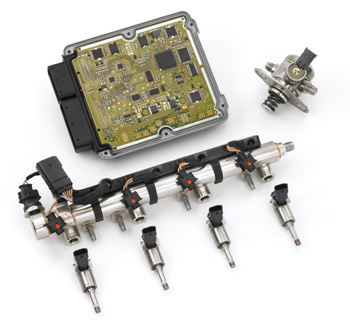

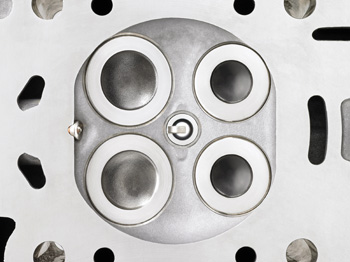

To accommodate the direct injection system, the Ecotec Turbo has a unique cylinder head and intake manifold. The cylinder head incorporates mounting locations for the fuel injectors — which are typically mounted in the intake ports or intake manifold on port injection engines. A high-pressure fuel pump delivers fuel to a variable-pressure fuel rail. Fuel enters the combustion chamber through precision multi-hole fuel injectors. The fuel pump, fuel rail pressure, fuel injection timing and injection duration are controlled by the engine control module. In this way, the fuel is metered and delivered in a finely atomized spray.

Apart from the mounting positions of the fuel injectors, the cylinder head has conventional port and combustion chamber designs, although both are optimized for direct injection and high boost pressures. The sodium-filled exhaust valves and stainless steel exhaust manifold are durable components designed to stand up to the high-performance capability of the engine.

Apart from the mounting positions of the fuel injectors, the cylinder head has conventional port and combustion chamber designs, although both are optimized for direct injection and high boost pressures. The sodium-filled exhaust valves and stainless steel exhaust manifold are durable components designed to stand up to the high-performance capability of the engine.

The unique cylinder head, fuel system, pistons, intake manifold and the dual-scroll turbocharger are the only major components that differentiate the 2.0L Turbo from other members of the Ecotec engine family.

Ecotec 2.0L Turbo engine highlights:

• Steel crankshaft

• Forged connecting rods

• Cast aluminum oil-galley pistons

• Jet-spray piston cooling

• 9.2:1 compression ratio

• Aluminum cylinder head with sodium-filled exhaust valves

• High-pressure engine-driven fuel pump

• Variable pressure fuel rail

• Dual-scroll turbocharger

Turbocharging System

A unique, dual-scroll turbocharger is partnered with an air-to-air intercooling system to provide up to approximately 20 psi of power-enhancing boost. The dual-scroll turbocharger delivers nearly instant response, as dual exhaust passages from the engine to the turbine housing guide exhaust gas to the turbine. This reduces lag time, or spool-up, at low rpm.

The turbocharger is matched to the engine’s displacement and performance objectives. It’s supported by the air-to-air intercooling system, which uses fresh air drawn through a heat exchanger to reduce the temperature of the warmer compressed air forced through the intake system by the turbocharger. Inlet temperature is reduced by approximately 212° F (100° C), enhancing performance because cooler air is denser and promotes optimal combustion.

The turbocharger is matched to the engine’s displacement and performance objectives. It’s supported by the air-to-air intercooling system, which uses fresh air drawn through a heat exchanger to reduce the temperature of the warmer compressed air forced through the intake system by the turbocharger. Inlet temperature is reduced by approximately 212° F (100° C), enhancing performance because cooler air is denser and promotes optimal combustion.

Dual Cam Phasing

The camshafts of the Ecotec Turbo engine have phasers that support the continuously variable intake and exhaust valve timing. They also have cam position sensors, so that the engine control module can accurately control valve timing. The crankshaft and camshaft position sensors are digital. A new engine controller, specific to the engine, is used to sense and control the engine’s performance parameters.

Variable intake and exhaust timing works synergistically with both the gasoline direct injection and turbocharging systems. The variable engine timing enabled by cam phasing allows the combustion process to be optimized. Also, valve “overlap” at low rpm can be adjusted by the controller to increase the response of the turbocharger, providing a more immediate feeling of power.

Family Ties

Family Ties

The Ecotec 2.0L Turbo was built on a global platform that was designed at the outset for a range of performance and combustion capabilities. The Gen II block supports the high-performance demands of the engine, but it is merely a strengthened version of the original Ecotec architecture. The oil pump, mentioned earlier, is the same as those used in all other Ecotec engines, and was originally designed to support high-performance applications of future engines.

As with other engines in the Ecotec family, the turbo version also has premium features designed to ensure smooth and quiet operation, including a polymer coating and skirt design for the pistons that reduces noise during cold starts. An automatic hydraulic tensioner also is used to maintain optimal tension on the timing chain, which reduces noise and vibration.

Some of the other traits the turbo design shared with the other Ecotec platforms include:

• Dual overhead camshafts (DOHC) and four valves per cylinder;

• Twin counter-rotating balance shafts for operational smoothness;

• Electronic throttle control;

• Low-friction, roller-finger follower valvetrain with hydraulic lash adjusters;

• Low-maintenance chain-drive for the camshafts;

• 58X crankshaft positioning;

• Direct-mount accessories, which reduce or eliminate traditional sources of noise and vibration; and

• Full-circle transmission mount to reduce noise and vibration.

GM Oil Life System

The Ecotec designers said the engine utilizes an oil life system that reduces the frequency of oil changes.

The system, which notifies the driver of needed oil changes on the dashboard display, uses an algorithm that tracks engine revolutions and temperature and predicts oil life based on these parameters and driver use.

GM engineers report that with their Oil Life System, the average GM vehicle typically needs oil changes half as often as the 3,000-mile recommendation. Based on driving 15,000 miles per year, this could mean between two to three fewer oil changes annually.

As many of you who perform oil changes know, more than 97% of GM vehicles sold in U.S. are equipped with this Oil Life System. GM reports that there are more than 31 million GM vehicles on U.S. roads that are equipped with the system.

For those who are changing the oil on these engines, the Ecotec’s oil system design incorporates a cast-in oil filter housing, which eliminates the need to be under the vehicle to perform oil changes and eliminates throwaway oil filter cans that retain used oil.

Engineers said that synthetic oil is recommended for this engine.

GM’s Direct Injection Explained

Gasoline direct injection differs from the fuel delivery process of a conventional engine by delivering fuel directly into the combustion chamber, where it is mixed with air drawn into the chamber. The combustion process of conventional fuel-injected engines uses air and fuel that are mixed in the intake port or intake manifold prior to being introduced into the combustion chamber.

Direct injection is a continuation of the evolutionary process of moving the fuel introduction point closer to the combustion location to improve control.

With the Ecotec 2.0L Turbo, fuel is introduced directly to the combustion chamber during the intake stroke. As the piston approaches top-dead center, the spark plug ignites the mixture, giving the name spark ignition direct injection (SIDI). The fuel injectors are located beneath the intake ports. SIDI allows the mixture to be “leaner” — less fuel, more air — at full power.

SIDI also permits a slightly higher compression ratio than if the fuel were delivered with conventional fuel injection. The result is better fuel consumption at part and full throttle. The engine uses conventional spark plugs similar to those in other Ecotec engines.

SIDI also permits a slightly higher compression ratio than if the fuel were delivered with conventional fuel injection. The result is better fuel consumption at part and full throttle. The engine uses conventional spark plugs similar to those in other Ecotec engines.

A high-pressure, returnless fuel system is employed. It features a high-strength stainless steel fuel line that feeds a variable-pressure fuel rail. Direct injection requires higher fuel pressure than conventional fuel-injected engines, and an engine-driven high-pressure fuel pump is used to supply up to 2,250 psi of pressure. The system regulates lower fuel pressure at idle — approximately 752 psi and higher pressure at wide-open throttle. The cam-driven high-pressure pumps works in conjunction with a conventional fuel tank-mounted supply pump.

Direct injection’s precise fuel delivery enables more complete combustion to help reduce emissions, particularly on cold starts — the time when most engine emissions are typically created. Also, direct injection permits a higher compression ratio in the engine, which positively influences fuel economy. At certain power levels, the boosted SIDI engine can provide significant fuel economy benefits compared to a larger displacement naturally aspirated engine.

Source: General Motors