TCCI joined local and state leaders and partners to break ground on TCCI’s new electric vehicle (EV) Innovation Hub in Decatur, Illinois. A manufacturer of electric compressors for commercial, heavy-duty and automotive specialty markets, TCCI’s EV Innovation Hub is a part of Illinois’ growing EV ecosystem.

“Not only will this new hub support the launch of one of the first made-in-America electric compressor manufacturing facilities, but it will also house the new Climatic Center for Innovation and Research, specifically designed to push the bounds of possibility in electric vehicles,” said Governor JB Pritzker. “Illinois’ clean energy and electric vehicle industries are on the rise, and these investments are lifting up our talented workforce and demonstrating to the world that Illinois is once again open for business, and we’re fast becoming the most promising state in the country to invest in.”

Bolstered by the State of Illinois’ Reimagining Energy and Vehicles in Illinois (REV Illinois) incentive package, which supports the manufacturing facility expansion, $21.3 million in capital grants were also appropriated to the City of Decatur and Richland Community College to build the Climatic Center for Innovation and Research, as well as the EV + Energy Workforce Training Academy, the company said.

“This three-tiered project represents a historic investment in American manufacturing and a major step toward establishing a full EV supply chain in the US, from supplies to talent,” said TCCI President Richard Demirjian. “It’s fitting that Decatur, on the same site where we have produced compressors since 1984, will now play a critical role in driving the global transportation sector toward an exciting future of electrification.”

Headquartered in Decatur, TCCI’s hopes to support the growth of electrification and create high-wage, skilled jobs that fuel economic development in the local community. Production is slated to begin by the third quarter of 2024.

A major component of the innovation hub is building a skilled workforce, the company said. The EV + Energy Workforce Training Academy will develop a skilled workforce in the electrified transportation industry and clean energy sector by preparing students to either enter directly into high wage jobs with their Associate in Applied Science (AAS) or Associate in Science (AS) degree or by transferring to a university through 2+2 programs and articulations agreements. Through the program, Richland Community College (RCC) will have three classrooms located within the TCCI manufacturing facility for an immersive hands-on learning experience. Articulation agreements have been signed between Richland Community College and the University of Illinois Grainger College of Engineering, University of Illinois College of ACES and Northern Illinois University to ensure a seamless transfer of credits for students, allowing them to pursue their educational journey in these fields without barriers, the company said.

Together, educational institutions in partnership with TCCI are developing specialized programs in engineering, computer science, data science, material science, advanced manufacturing, biology, chemistry and more. These programs will prepare individuals for the fields of climate technology, electric vehicle manufacturing, and related energy and agriculture industries, TCCI said.

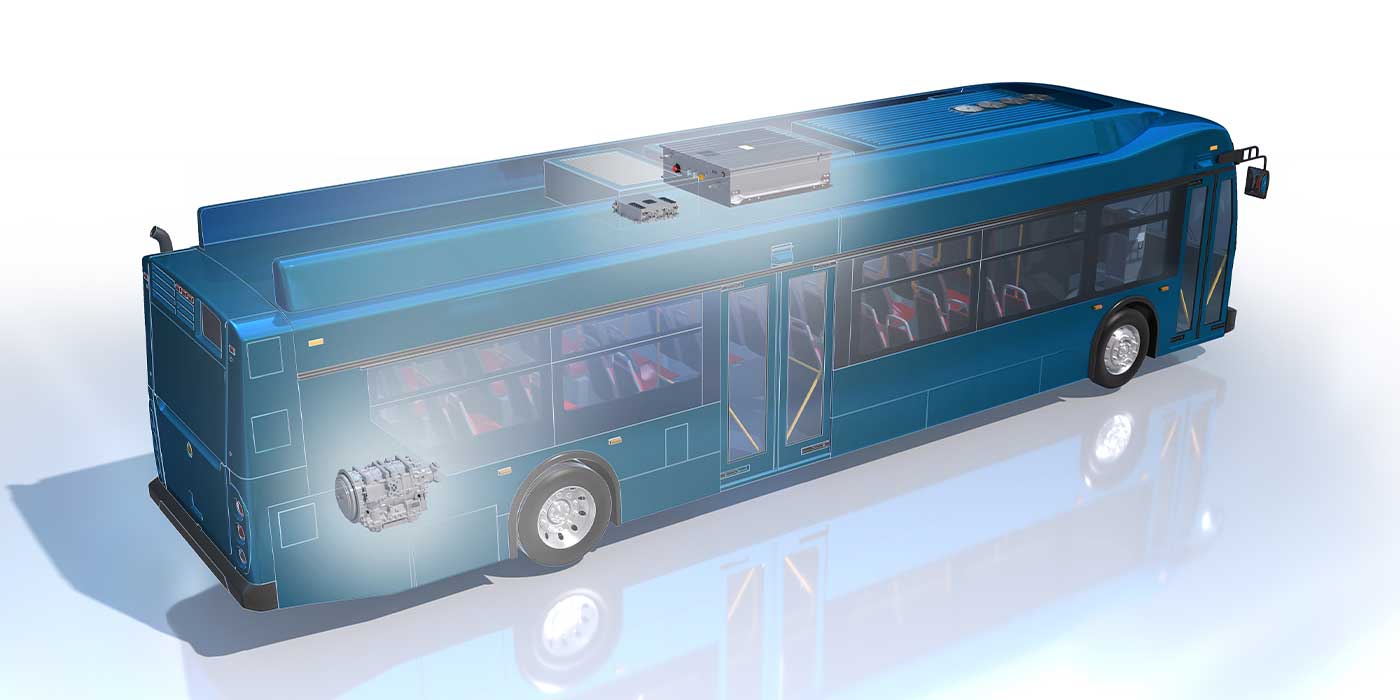

The Climatic Center for Innovation and Research (CCIR) is an R+D facility equipped with climatic testing capabilities specifically designed for electric vehicles. Its 65-foot by 25-foot climatic chamber is equipped with a DC fast charger to accommodate heavy-duty and oversized vehicles and observe system performance under extreme environmental conditions while charging at max input, the company said.

The chamber will have testing capabilities for solar, humidity and ambient temperatures as low as minus 30 degrees to plus 130 degrees Fahrenheit.