As modern OBD II technology marches on, it’s clear that the zirconia-based oxygen sensor now is being sold more as a basic repair part than as a preventive maintenance part, and it changes the way we diagnose and sell oxygen sensors. To illustrate the difference, let’s remember that an oxygen sensor replacement used to be considered part of an engine “tune up” that may have involved periodically adjusting air/fuel mixtures, ignition timing, idle speeds, valve lash and replacing fouled spark plugs. Today, most shops replace spark plugs and filters as part of scheduled maintenance and, when a malfunction indicator engine light (MIL) complaint does arise, they use scan tool-based technology to determine if an oxygen sensor is the cause.

Of course, let’s keep in mind that, during the early ’80s, oxygen sensors quickly became contaminated with fuel-borne dirt and ethyl lead gasoline, not to mention oil ash from oil-consuming engines. In most cases, the OBD I check engine light wouldn’t illuminate until the oxygen sensor became marginal in performance.

Today, fuel is refined to higher standards and engines run much cleaner, which means than an oxygen sensor replacement is needed only when an OBD II system detects degradation in oxygen sensor performance. When degradation is detected, the PCM turns on the MIL to warn the driver and to indicate to the technician that an oxygen sensor-related diagnostic trouble code has been stored in the PCM’s diagnostic memory.

OXYGEN SENSOR FUNCTIONS

Since the oxygen sensor’s main function in pre-1996 OBD I imports was fuel control, most applications employed just one oxygen sensor. The fuel control function varied since an oxygen sensor might have a 90 percent fuel control authority or it might have a 10 percent fuel control authority, depending upon engine management programming. As for symptoms, a failed oxygen sensor in a system with 90 percent authority may cause an engine to run rich, while it may have little effect in a system with 10 percent authority.

Evaluating the OBD I fuel control function involves using a voltmeter or lab scope to measure the voltage activity of the oxygen sensor itself. Lab scopes are the more accurate method because the voltage range and switching pattern of the oxygen sensor’s voltage input to the PCM can be observed as a waveform.

In contrast, OBD II systems use multiple oxygen sensors to perform three different functions: To monitor catalyst efficiency; to establish fuel control and fuel trim numbers; and to measure bank-to-bank fuel trims. Driveability symptoms are rarely evident when an OBD II oxygen sensor fails because modern OBD II programming is such that even the smallest degradations in oxygen sensor voltage activity can be detected over a wide range of operating conditions and mileage intervals.

THE CATALYST FUNCTION

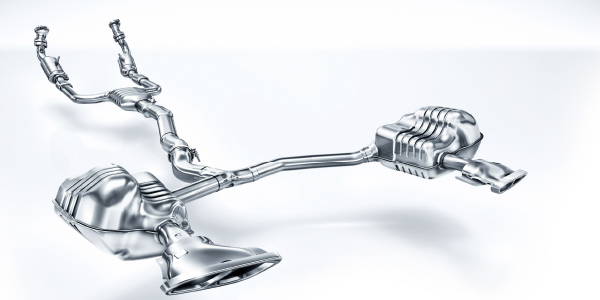

The catalyst function employs one upstream oxygen sensor placed before the inlet of the catalytic converter and one downstream sensor placed after the outlet of the converter. The primary function of the upstream sensor is fuel control, while the primary function of the downstream sensor is measuring the efficiency of the catalytic converter.

The PCM measures catalytic converter efficiency by mathematically comparing the voltage activity of the upstream sensor with that of the downstream sensor. If the converter is operating efficiently, the upstream sensor voltage will be highly active, while the downstream sensor will be dramatically less active. As the catalytic converter degrades, the voltage activity of the downstream sensor will more closely follow that of the upstream sensor. When a mathematically critical level of activity is reached on the downstream sensor, the PCM will typically store a converter-related DTC and illuminate the orange check engine warning light.

While we’re talking about using oxygen sensors to measure catalytic converter efficiency, always keep in mind that coolant from a leaking cylinder head gasket will contaminate both oxygen sensors and the catalytic converter itself. Whenever oxygen sensor and converter trouble codes appear simultaneously, always suspect that head gasket leakage might be the cause.

THE FUEL TRIM FUNCTION

By comparing oxygen sensor voltage with fuel injector pulse width, a PCM can generate a fuel trim number. To illustrate in very basic terms, let’s say that, under perfect operating conditions, the PCM is programmed to recognize that a fuel injector pulse width should be about eight milliseconds at 2,000 rpm at 30 percent throttle opening. If the engine develops a vacuum leak, the pulse width might rise to 10 milliseconds, which is a 25 percent increase from perfect operating conditions.

Conversely, if a fuel pressure regulator is leaking into the intake manifold and artificially richening the air/fuel ratio, the PCM will subtract fuel in order to bring the oxygen sensor’s voltage activity in line with programmed levels. In other words, if pulse width was reduced from eight to six milliseconds to bring the oxygen sensor voltage in line, then the scan tool data stream might display a -25 percent fuel trim.

THE BANK-TO-BANK FUNCTION

If a vacuum leak develops on number-one bank or the “B1” of a V-type engine, then the B1 upstream sensor may show a +25 percent fuel trim number on a scan tool data stream. This means that the PCM is adding fuel in order to maintain oxygen sensor voltage activity on the B1 upstream oxygen sensor. In contrast, the B2 or bank 2 upstream fuel trim may be only slightly affected by the vacuum leak on bank one.

When analyzing bank-to-bank fuel trims, it’s important to understand that two oxygen sensors seldom fail simultaneously or in the same manner. Let’s say that both the upstream and the downstream oxygen sensors are producing lower-than-normal voltage and that the B1-1 and B2-1 upstream fuel trims are showing +15 percent. Obviously, this +15 percent trim might be caused by low fuel pressure or by a bad air flow sensor sending an erroneous air flow reading to the PCM.

Similarly, high fuel pressure or restricted air flow might cause a -20 percent fuel trim because the PCM is removing, rather than adding, fuel in order to maintain correct oxygen sensor voltage activity.

THE OXYGEN SENSOR MARKET

With the advent of OBD II diagnostics, zirconia oxygen sensors are more likely to be sold as repair items in the current service market. All OBD II imports are equipped with multiple oxygen sensors, most of which will fail during the service life of the vehicle. Although the zirconia oxygen sensor market has swung from preventive to repair during the past decade, the outlook for profitability looks brighter than ever.