LG Energy Solution and Toyota Motor North America have signed a supply agreement for lithium-ion battery modules to be used in Toyota battery electric vehicles (BEVs) that will be assembled in the United States.

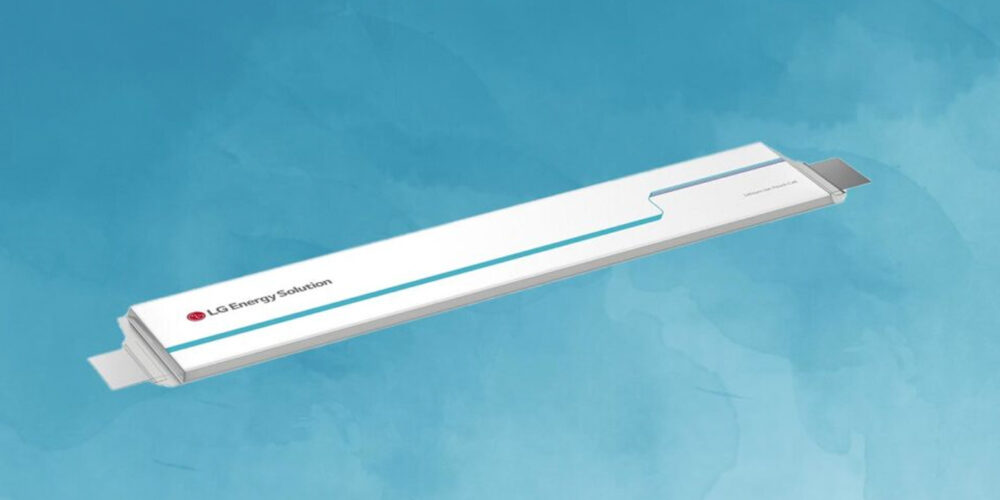

Under the contract, LG Energy Solution will supply automotive battery modules at an annual capacity of 20GWh starting from 2025. The battery modules, consisting of high-nickel NCMA (nickel, cobalt, manganese, aluminum) pouch-type cells, will be manufactured in LG Energy Solution’s Michigan facility, the companies said.

The solutions will support Toyota’s expanding line of BEVs, part of its multi-pathway product strategy, including a new BEV model that will be assembled at Toyota Motor Manufacturing Kentucky in 2025. They will also help further Toyota’s vehicle electrification initiatives, as it aspires to offer 30 BEV models globally across its Toyota and Lexus brand nameplates and produce up to 3.5 million BEVs annually by 2030.

To fulfill the supply agreement, LG Energy Solution will invest KRW 4 trillion (approximately $3 billion) in its Michigan facility to establish new production lines for battery cells and modules exclusively for Toyota, with completion slated for 2025, the companies said. Initially, the battery modules will go to Toyota Motor Manufacturing Kentucky to be assembled into battery packs and equipped onto BEVs.

The recent deal represents LG Energy Solution’s largest single supply agreement secured outside of joint venture agreements. The company now supplies its batteries to all top five global automakers, the companies note. The company has eight battery manufacturing facilities currently operating or under construction in North America.