All too often, we wonder where to begin when we get a cooling system overheating complaint in our service bay. Is the water pump impellor slipping or is the radiator core partially clogged? Perhaps the best way to begin is by using a series of quick, non-intrusive cooling system tests that establish the basics without removing major parts. With the word “non-intrusive in mind, let’s begin our basic diagnosis by looking at the coolant level in the cooling system reservoir. See Photo 1.

COOLANT RESERVOIR INSPECTIONS

Coolant reservoirs provide important clues about the condition of the cooling system. To illustrate, a small amount of coolant loss is normal over a length of time. But, an extremely low coolant level usually indicates the presence of a coolant leak at the water pump, hoses, radiator, heater core, intake manifold gaskets or cylinder head gaskets. If the reservoir is empty, the system must be refilled and pressure-tested to identify external leaks.

Next, check the color and opacity of the coolant. If, for example, the color of the OE coolant is red and the reservoir is filled with green coolant, the coolant might not meet OE specifications. In this case, flush the cooling system and install the correct coolant mixture. If the coolant is opaque or clouded, the system might be filled with stop-leak or might contain an additive that reacts with the coolant.

The presence of oil in the coolant reservoir usually indicates that the transmission oil cooler is leaking into the radiator. A rusty transmission dipstick will usually confirm this condition. If the oil is black or tan in color, a crack in the engine block or cylinder head might be leaking oil into the engine’s water jackets. If the crankcase oil is milky or viscous, suspect a cylinder head gasket leak.

Last, always test the coolant’s freezing point. In most applications, the coolant/water mix should be 50/50 for the best freezing and boiling point protection. Keep in mind that it’s nearly impossible to accurately blend coolant and water in an open container. When available, it’s easier and far more accurate to install a premixed 50/50 coolant.

COOLING SYSTEM CAPS

In some cases, an engine cooling fan might not activate until engine temperatures exceed 220-230° F operating temperature, which is near the boiling point of many coolant mixtures. Consequently, modern import cooling systems must maintain adequate pressure to prevent the coolant from boiling under extreme operating conditions. See Photo 2.

If the radiator or cooling system cap is coated with rust and the gaskets or O-rings are cracked or hardened, the cap should be replaced. The presence of rust sediment inhibits the ability of the cap to maintain pressure as the system warms up or release vacuum as the system cools down.

If heavy rust is present on the cap, the cylinder block water jackets likely contain heavy sediment deposits. If the engine overheats and boils these deposits out of the block, the sediment will also tend to clog the radiator. If the coolant is excessively rusty, the metal water pump impellor might be corroding. The presence of rust is never good and nearly always indicates heavy corrosion and wear throughout the system.

SERPENTINE BELTS

Always inspect the serpentine belt for cracking, glazing or fraying, and check the belt tensioner indicator marks for excessive belt wear (See Photo 3). If the water pump is visible, check for seal leakage at the drain hole behind the belt pulley. If the water pump isn’t visible, check for coolant seepage at the bottom of the timing cover.

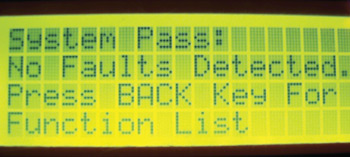

DIAGNOSTIC TROUBLE CODES

Although it might appear optional, checking for diagnostic trouble codes (DTCs) is an important part of modern cooling system service (See Photo 4). An inexpensive “generic” or “global” scan tool can quickly retrieve pending, current and history codes indicating thermostat, coolant temperature sensor or cooling fan malfunctions on post-1996 OBD II vehicles. Retrieving trouble codes is important because an out-of-range engine coolant temperature sensor can, for example, affect cooling fan operation or inhibit operation of the air conditioner compressor.

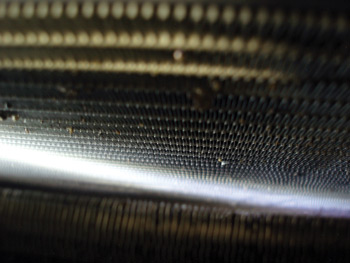

AIR FLOW

When investigating an overheating complaint, don’t forget to inspect between the A/C condenser and radiator cores for debris that might be inhibiting air flow (See Photo 5). Some vehicle designs are also notorious for drawing leaves and road debris into the area between the A/C condenser and radiator. Although inspecting this area might require removing some core support panels, the effort could reveal a severe restriction of air flow. Similarly, aftermarket bug screens, front-mounted spare tire carriers and missing undercar spoilers will disrupt air flow through the A/C condenser and radiator cores.

In all cases, the air flow through the grille and engine compartment must support adequate engine cooling. In general, restricted air flow usually causes an overheating complaint at highway speeds. Restricted coolant flow through the thermostat or radiator will cause similar high-speed or high-load overheating complaints.

CLEANING RADIATOR EXTERIORS

Because access is a problem, special tools might be required to remove debris from A/C condenser and radiator exteriors. Photo 6 illustrates two homemade air nozzle extensions designed to reach into the narrow area between the A/C and radiator cores. A right-angle nozzle will remove leaves and other debris. If the radiator surface is badly clogged with insect and road debris, the radiator might require removal for a more thorough cleaning.

COMPRESSED AIR WARNINGS

Care should be taken when using compressed air to remove debris from radiators. To avoid personal injury and damage to the vehicle, it’s important to have a firm grip on any manufactured or homemade compressed air nozzle equipped with an extended outlet (See Photo 7). In general, air pressure should be regulated to a maximum of 90 psi to avoid flattening the aluminum cooling fins in the radiator core. In most cases, lower air pressures will quickly remove all loose debris.

On a similar note, modern aluminum radiator cores can easily be ruined by using pressure washers or high-pressure water hoses to clean a radiator or A/C condenser core. High water or air pressure will flatten the cooling fin and further aggravate air circulation problems through the radiator.

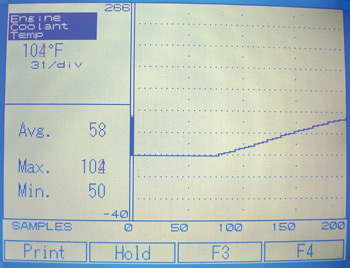

SCAN TOOL GRAPHING

A scan-tool graph of the temperature increase from cold-soak to full operating temperature can be used to analyze thermostat and water pump operation. As illustrated in Photo 8, the coolant temperature should quickly begin to rise. Coolant temperatures that rise erratically or too quickly might indicate a slipping or badly corroded bad water pump impellor. A slow temperature rise accompanied by a hot upper radiator hose might indicate a stuck-open thermostat.

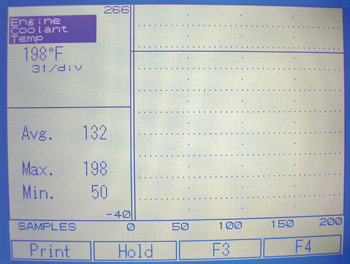

If the thermostat and coolant temperature sensor are operating correctly, the coolant temperature should plateau at or near rated thermostat temperature with a constant air flow through the radiator (See Photo 9.) The required air flow can usually be achieved by turning on the air conditioner or by using an external, high-volume floor fan. If the temperature rises beyond the thermostat’s rated temperature, suspect a defective thermostat, water pump impellor or clogged radiator core.

Always verify the accuracy of the ECT sensor by measuring coolant temperature at the thermostat housing with a non-contact or infrared pyrometer (See Photo 10). In many cases, the reflectivity of the housing will affect temperature readings. A more accurate reading can be achieved if your pyrometer incorporates a laser-beam locator and a maximum temperature reading. The maximum (and most accurate) temperature reading can be obtained by waving the laser beam across the thermostat housing and cylinder head surfaces.