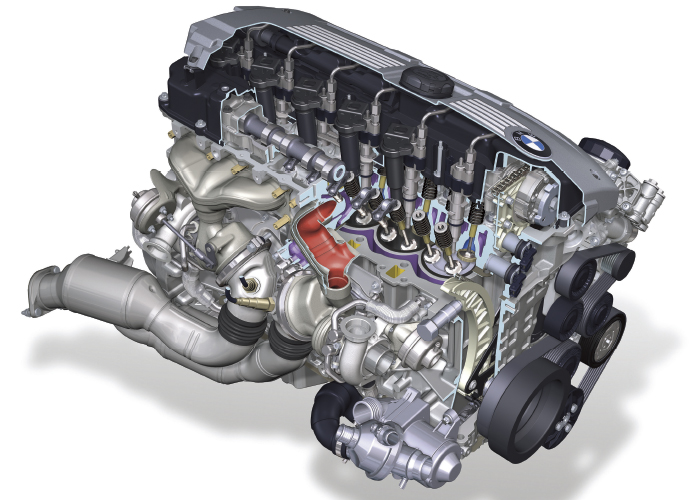

German engineering is often considered much more than just a marketing slogan these days, thanks to the quality of the products from manufacturers such as BMW and Mercedes-Benz. Yet, for all of their forward-thinking concepts and advanced engine designs, as these vehicles get older and rack up high mileage, some problems begin to be seen with the crankcase ventilation system and intake manifolds. Typically a high-density plastic material, this material can become brittle over time and from exposure to the high heat environment in which they live.

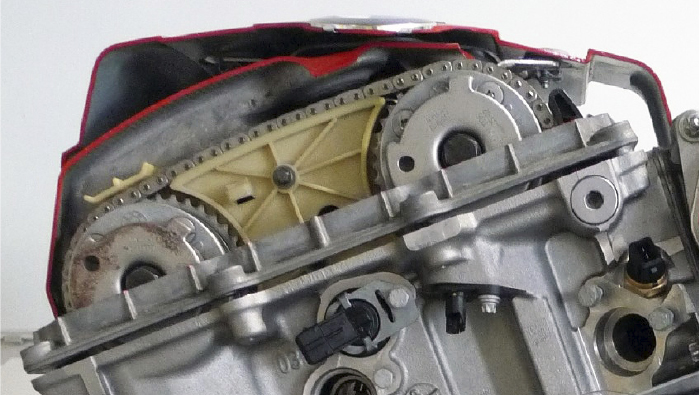

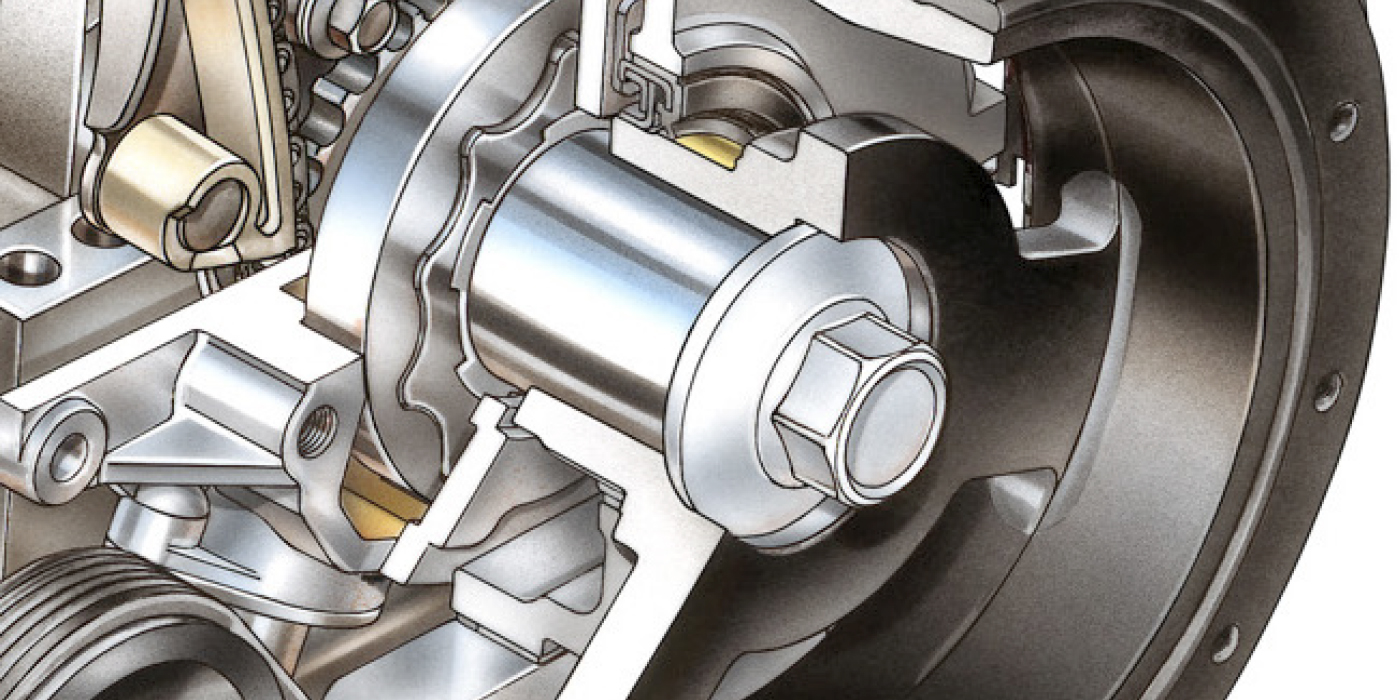

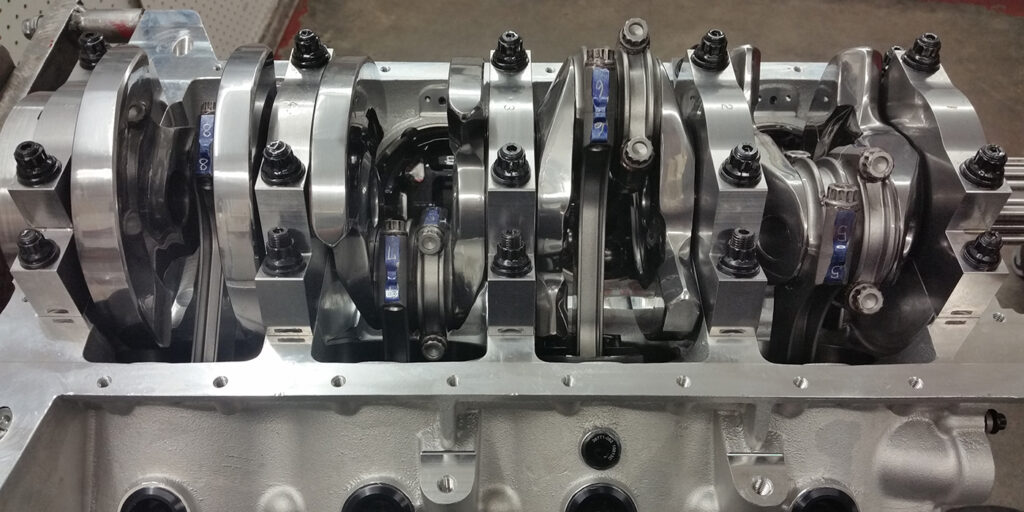

Many BMW engines, from the M52 to N54 and other variants, experience leaks around the oil filter housing. At first, this is just a mild irritation, but as the vehicle ages and the leak increases, it can become a big problem. On some engines, such as the N52, the housing tends to leak directly onto the serpentine belt, which can cause slippage and overheat the belt. In some cases, the belt will slip off the pulley and shards of rubber wrap around and behind the crankshaft dampener, breaching the seal and distributing bits of rubber into the timing cover. It’s unclear why BMW has never addressed this issue since it is shared across the 3 Series engine line.

It is recommended to change the serpentine belt and tensioner and the coolant flange whenever the oil filter housing gasket is replaced. The gasket itself is made of silicone rubber that becomes brittle and compacted over time. If the leak is caught early enough, you will have to replace only the gasket, but when the leak gets significant enough, it is better to be safe and replace the belt as well. The belt can swell up as the oil drips onto it.

Most BMW valve covers and intake manifolds are made of plastic to reduce weight and production costs, but as with most things that age, these components are susceptible to warpage and gasket failure due to the constant heating and cooling they experience. If you’re replacing a valve cover gasket (which is usually a molded silicone rubber), it is crucial to inspect the valve cover as well for warpage and cracks. High-mileage applications run through many heat cycles that tend to make the gaskets brittle. The tendency is to apply more clamp load on the fastener, but by that point, it may be too late. The gasket is already flattened, and the only thing you’re doing is applying uneven force to the valve cover, potentially warping or cracking it. Make sure to replace the rubber grommet washers if they are split and broken. Many valve cover kits include the washers.

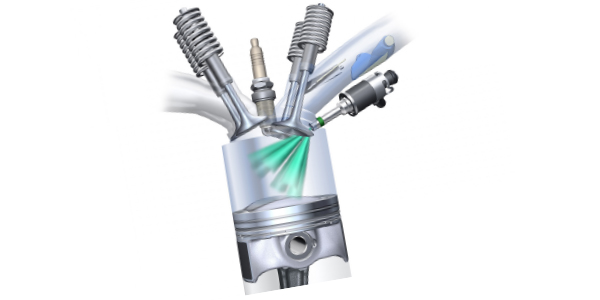

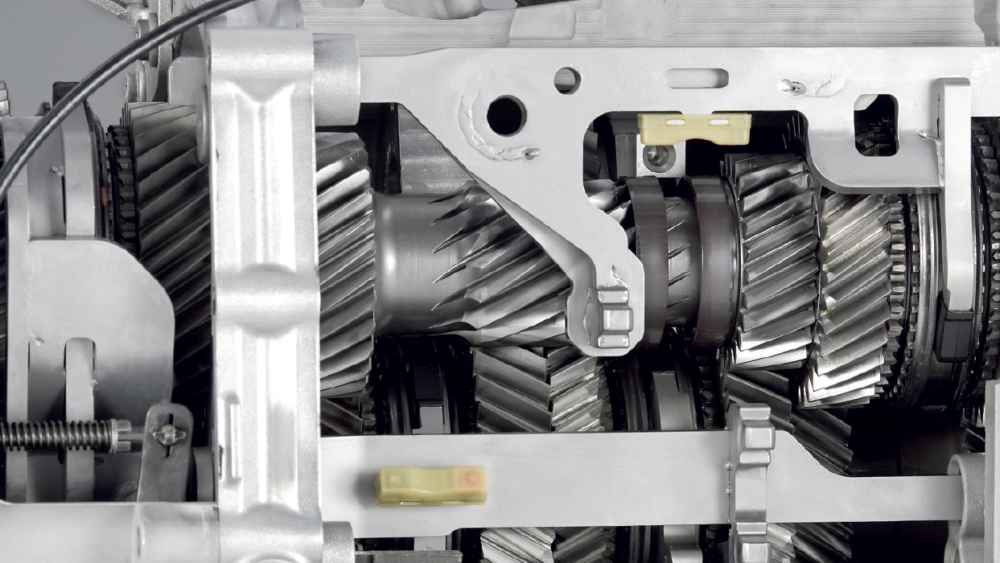

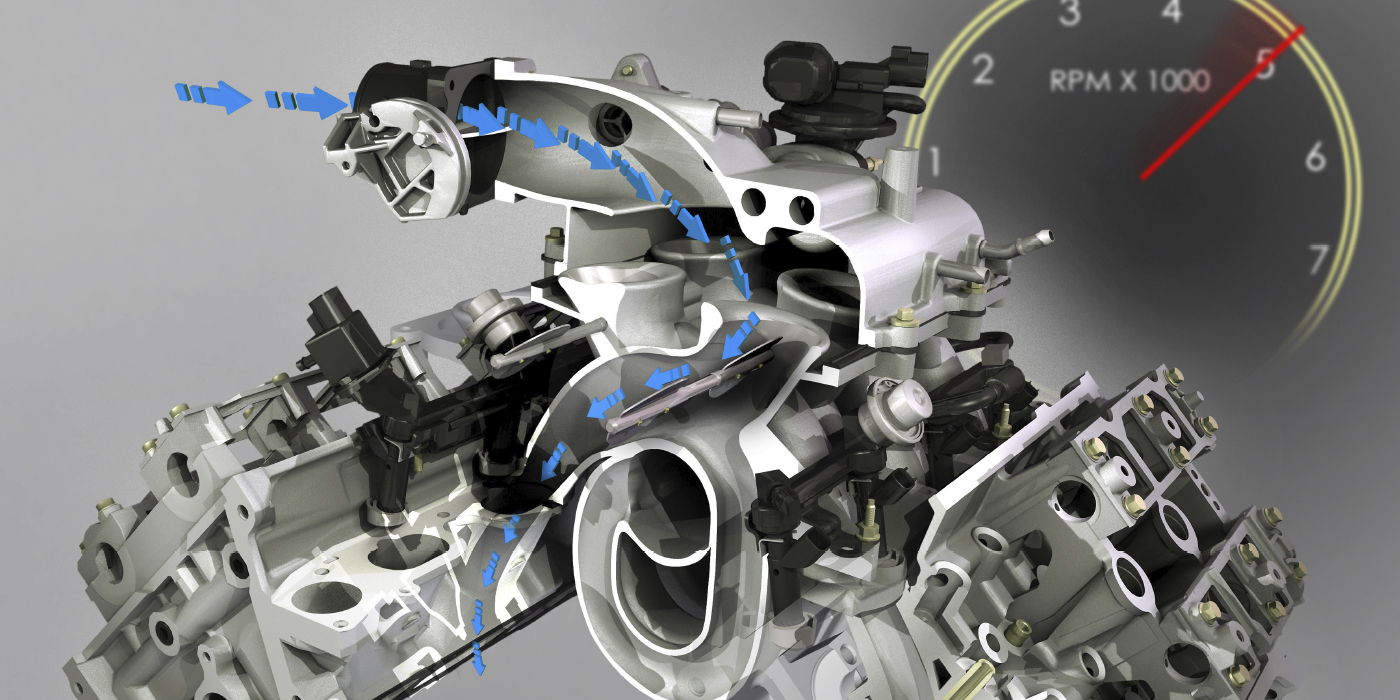

Many older BMW engines use an intake system known as DISA (from the German term “Differenzierte Sauganlage,” which means differential air intake). BMW intake manifold gaskets and DISA valves can also leak (air) due to high underhood temperature cycles. The constant heating and cooling may lead to the silicone gasket no longer being able to make a good seal. The DISA valve optimizes the engine performance under partial and full load as it adjusts the intake runner length. The valve is located in the inlet plenum chamber and controls the variable-length intake manifold (similar to Mercedes, but less complicated). It can lead to a rough idle, performance loss, and reports of a rattling noise, along with a DTC when it fails. If the car shows signs of rough running or reduced performance, it may be the DISA valve. There are kits to replace the flap and silicone gasket, but the only choice may be to replace the complete unit if it is already broken.

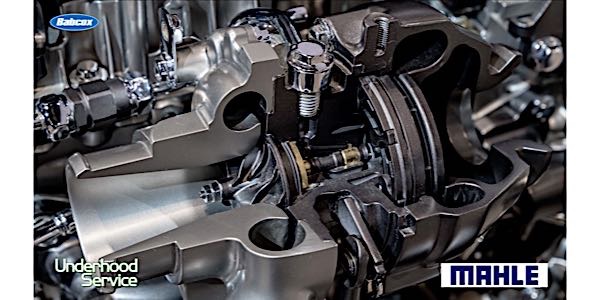

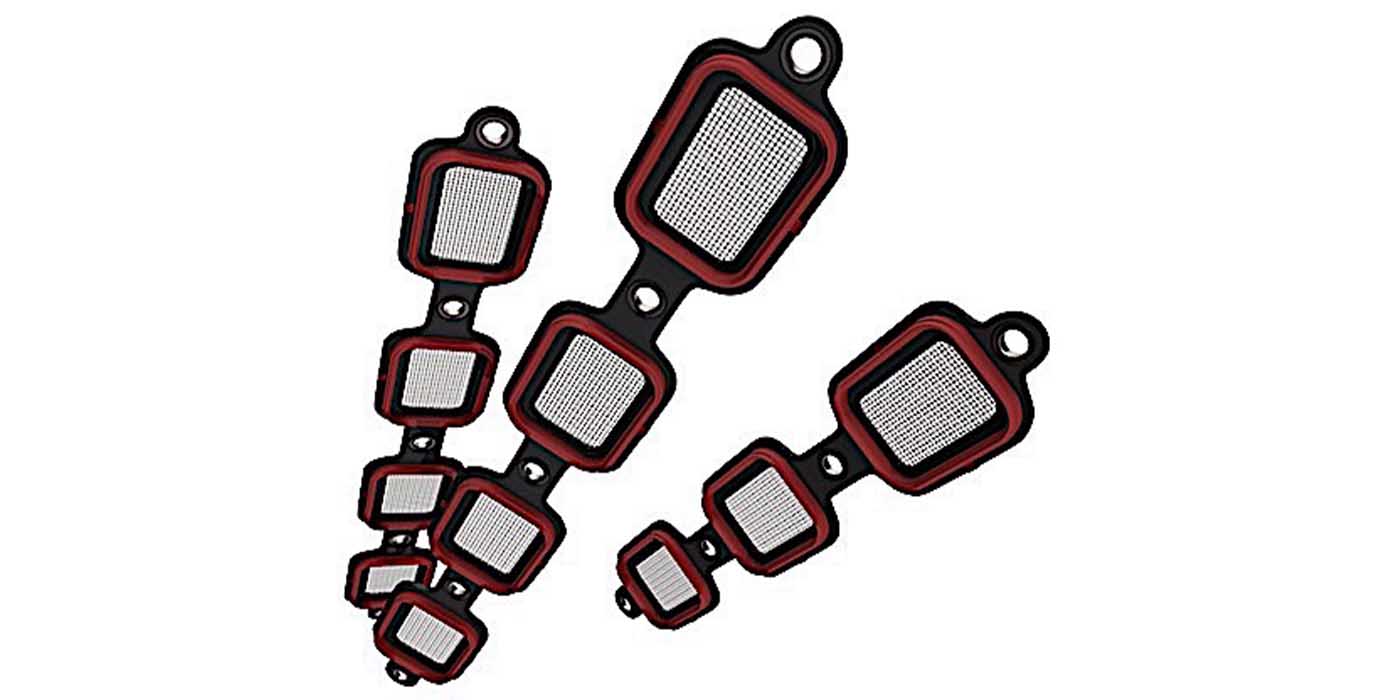

A similar manifold issue found on some Mercedes with 3.0-3.5L V6 engines (M272 or M273) display symptoms like the BMW DISA with poor idle, loss of power and a DTC. The issue is caused by an inlet manifold tuning flap breaking in one of the variable-length runners. These typically involve one of the actuators for the variable system, which causes one to become disconnected or broken. If the engine oil service is not properly adhered to, the intake can become covered with oil and crud from the PCV system, making the flaps work extra hard until one eventually breaks.

Mercedes intake manifold failures usually happen when vehicles reach higher mileage (80,000-100,000 miles). The plastic actuators and linkage found on the OE parts are the weak link and typically break in one of those places. The only way to repair them is to pull the intake manifold. In some worst-case scenarios, the defective plastic bushing can break off and get sucked into one of the cylinders. This is almost certain to lead to bent valves and a destroyed cylinder head. The replacement part uses a steel cam lever and actuator arm.

Of course, these cars are well-built and should last for many years, but there’s always an Achilles heel to deal with no matter what. With the level of plastic components projected to only increase in the future, the reality is there will be failures of these parts as vehicles age and run through many heat cycles. It’s best to be proactive with the known issue and save your customer some grief and a little money in the long run.