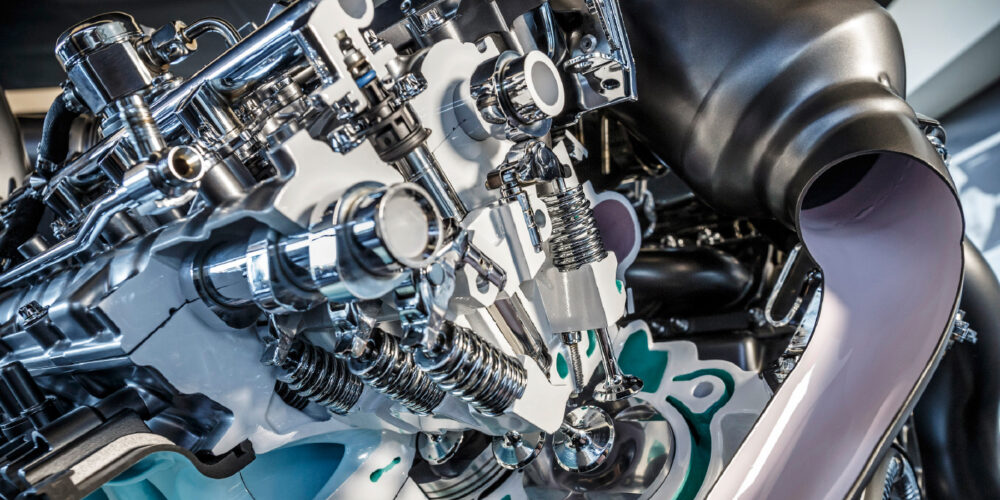

Cork/Composite Gaskets

Sealants: Cork and composite gaskets can seal a variety of underhood applications from valve covers to carburetors. The type of sealant used with these gaskets depends on a variety of factors. First, you must consider if the gasket needs to remain flexible. Second, you need to consider the temperatures the sealant will have to endure. Third, what types of chemicals and fluids will come in contact with the sealant?

Sealants: Cork and composite gaskets can seal a variety of underhood applications from valve covers to carburetors. The type of sealant used with these gaskets depends on a variety of factors. First, you must consider if the gasket needs to remain flexible. Second, you need to consider the temperatures the sealant will have to endure. Third, what types of chemicals and fluids will come in contact with the sealant?

Surface Finish: Smooth. The surface should be free from old gasket material, imperfections and fluids.

Rubber/Silicone Gaskets

Sealant: None. Only small amounts of high-tack liquid sealant should be used in strategic areas to hold the gasket in place. Sealants can add thickness, which creates uneven clamping force since the gasket will not be able to seat properly. Also, sealant can extrude out when the gasket is compressed, and it could end up in an oil or coolant passage and restrict or block flow.

Surface Finish: The sealing surface should be clean and dry.

Metal/Plastic Carrier Gaskets

Metal/Plastic Carrier Gaskets

Sealants: Dry. The sealer can chemically attack the sealing beads and carrier material, causing them to degrade. Sealants can act as a lubricant and cause the rubber gasket to slip out of place and split. Also, RTV can extrude out when the gasket is compressed, and it could end up in an oil or coolant passage and restrict or block flow. If a carrier-style gasket requires a sealant, some will include a portion in the kit. Most replacement gasket manufacturers will include instructions for installation that will outline if sealants need to be applied.

Surface Finish: The sealing surfaces should be dry and clean. If the surface surrounding a port is rough and pitted, the new gasket may not seal any better than the old one. Resurfacing or replacing a component may be required to restore a smooth, flat surface.

O-Rings

Sealant: In most cases, no sealant is required. Most installation instructions advise that O-rings are to be coated with coolant or oil to lubricate the seal and allow the two components to expand and contract independently.

Surface Finish: Smooth and free from debris.

MLS Head Gasket

MLS Head Gasket

Sealants: Dry, unless otherwise specified by the manufacturer.

Surface Finish: Most aftermarket MLS gaskets can handle surface finishes as rough as 60 to 70 Ra microinches, but some specify a smoother finish of 30 to 50 Ra. Smoother is always better, and if you can get the finish down to the low teens or even single digits, great. For most applications though, a surface finish in the 20 to 30 Ra range is more than smooth enough for a performance MLS gasket.

Composite Head Gasket

Composite Head Gasket

Sealants: Dry.

Surface Finish: The surface finish should ideally be 60 to 80 Ra (360 to 480 Rz). Don’t go smoother than 40 Ra (240 Rz) or rougher than 100 Ra (600 Rz) with a composition gasket. Rougher surfaces limit gasket conformance, while smoother surfaces increase the tendency for gaskets to flow and reduces their blow out resistance.

Elastomeric Head Gasket

Sealants: None.

Surface Finish: These should be treated the same as MLS gaskets. Most elastomeric gaskets can handle surface finishes as rough as 60 to 70 Ra, but some specify a smoother finish of 30 to 50 Ra, so smoother is always better. Check with the gasket manufacturer for the correct surface finish.

No Gasket

Sealant: Some components like water outlets or front covers may need a bead of sealant to seal the component. You need to consider the temperatures the sealant will have to endure, and what types of chemicals and fluids the sealant will come in contact with. Lastly, consider if there is a possibility that some of the sealant could be ingested by the engine and possibly contaminate the oxygen sensor. If so, use a sealant that will not harm the sensor.