A smoke machine may seem like an expensive piece of equipment if it is just used for testing EVAP systems. But, if you factor in other diagnostic tests it can perform, it is a worthwhile investment.

1. PCV System : A leaking PCV system can cause unmetered air to enter the intake manifold. By pressurizing the crankcase with smoke, you can find leaks in not only the hoses and connections, but also other items like the valve cover and oil pan gaskets. The best place to connect the smoke machine is at the oil filler neck.

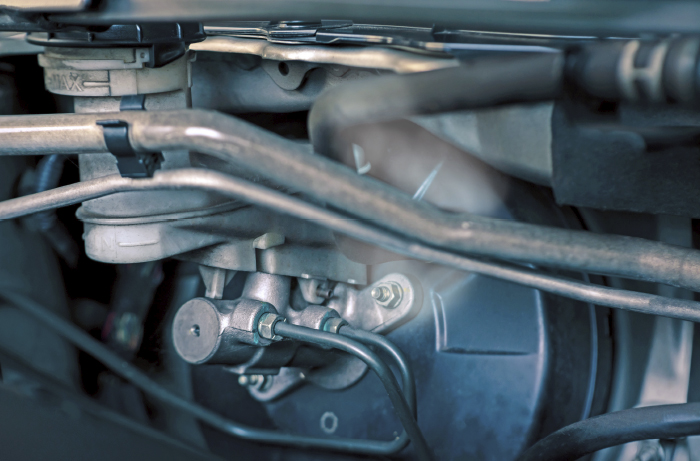

2. Injector Seals: Leaking injector seals can cause lean and misfire codes. Conventional testing methods often involve flammable gases or liquids and looking for a change in rpms. With a smoke machine, simply block off the air intake and PCV system and connect the smoke machine through a vacuum port. Injectors with leaky seals will start to emit smoke at the base.

3. Intake Manifold: Even the smallest leak can cause a fuel trim problem. A smoke machine allows you to diagnose multiple leaks in less time when compared to other methods. Connect the smoke machine to a vacuum port like the supply line to the brake booster. Make sure to block the throttle body.

4. Valves and Pistons: A compression tester will not tell you if an intake valve, exhaust valve or piston is causing a lack of compression. A smoke machine can, and without having to tear down the engine. With a cylinder at top dead center, connect the smoke machine to the spark plug port. If the smoke comes out the oil filler cap, it is the piston or rings. If the smoke comes out the intake, it is the intake valve. If the smoke comes out the tail pipe, it is the exhaust valve.

5. Brake Booster: Connect the smoke machine after the check valve and turn on the smoke machine. Any smoke coming out of the booster is a sign of a failed diaphragm of seals. Have an assistant depress the brake pedal several times while looking for leaks.

6. Exhaust System: Most late-model exhaust systems are clad in heat shields and are crammed next to firewalls and frames. A smoke machine can give you a definitive answer to what is leaking. Connect the smoke machine to the tail pipe with the appropriate adapter. Make sure the system is cool before turning on the smoke machine.

7. HVAC Vacuum Actuators and Switches: Vacuum actuators and controls can be hard to diagnose. Most smoke machines have a flow meter that can measure the size of a leak. With the smoke machine attached to the main vacuum supply line for the HVAC system, cycle the head unit through the different airflow patterns. If the gauge on the smoke machine registers a leak for a prolonged period of time, it is a sign the door actuator or switch could be faulty.

8. Transmissions and Axles: With the transmission or axle drained, block the breather and insert the smoke machine’s nozzle into the filler hole or dipstick tube. Leaks may first show up as bubbles or drips. This technique can be used to diagnose transfer case and transmission leaks that can contaminate the other’s sump.

9. Headlights: Modern Halogen and HID systems do not work well with moisture in the housings. By removing the bulbs and connecting the smoke machine, it is possible to inspect for leaks around seams.

10. Fluid Reservoirs: Plastic tanks like the ones for coolant and windshield washer fluid can develop cracks that cannot be seen with the naked eye. A smoke machine can make these leaks visible.