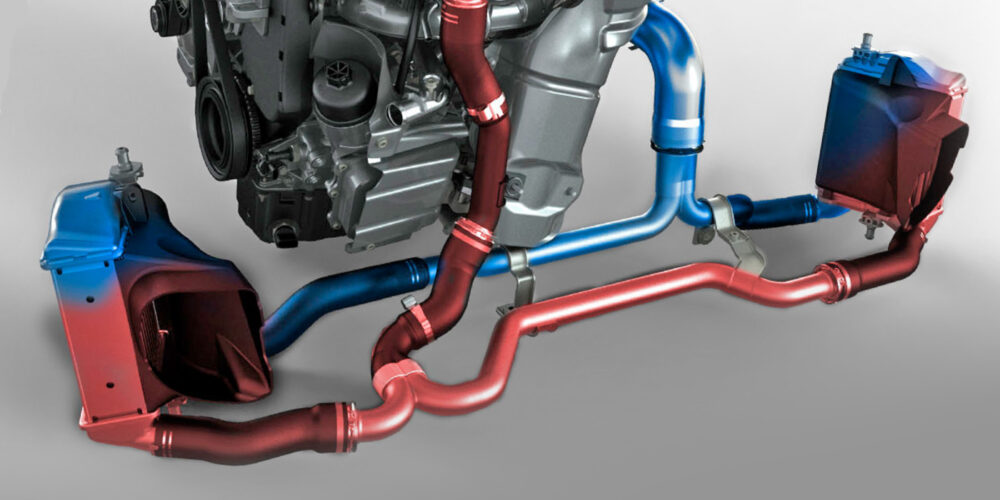

The first symptoms of a head gasket that is failing are usually a slow loss of coolant with no visible leaks, engine overheating and/or a Check Engine light with cylinder misfire codes.

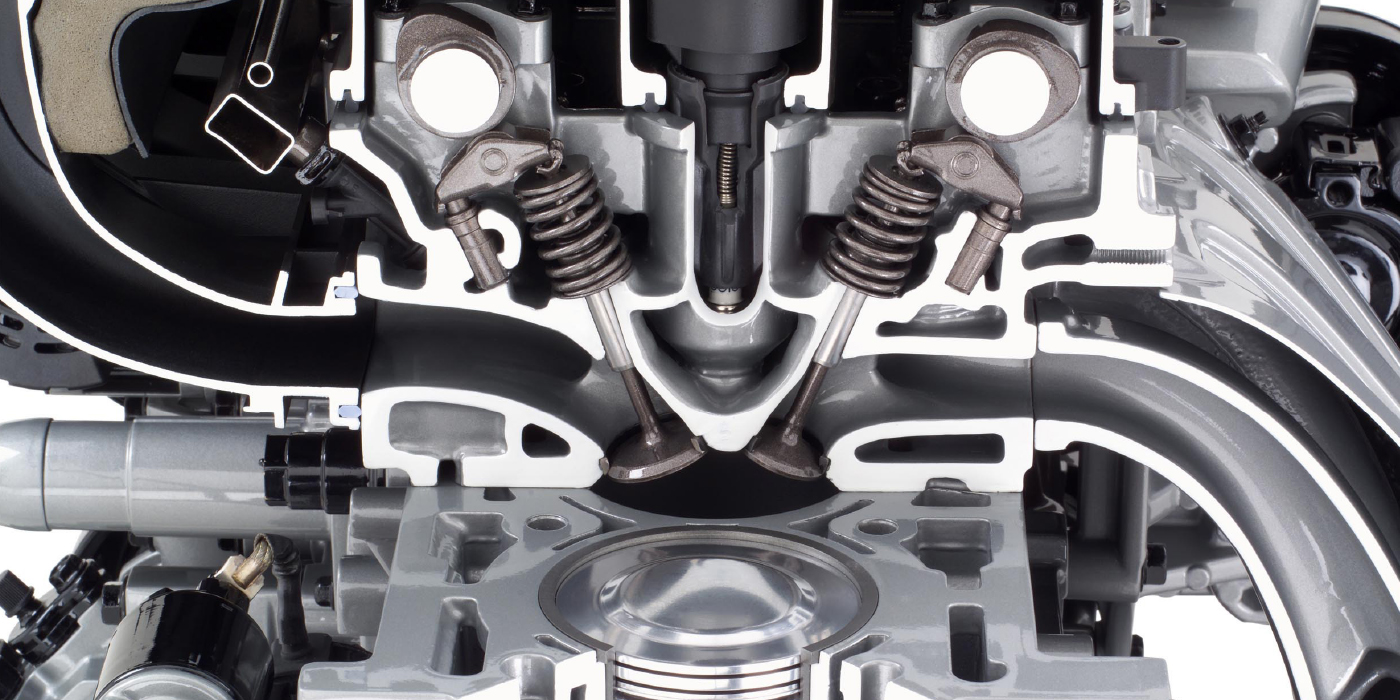

The Onboard Diagnostic II system should detect any misfires that occur due to a loss of compression or spark plugs fouled by coolant seeping into a combustion chamber. So if a vehicle has a Check Engine light on and a cylinder misfire code, the spark plug in that cylinder should be removed and inspected for coolant fouling. A compression or leak down test should also be done to see if the cylinder is losing compression. Internal coolant leaks caused by a leaky head gasket can usually be diagnosed by pressure testing the cooling system.

Regardless of the cause, a head gasket failure is bad news for the vehicle owner.

Depending on the application and how much labor it requires, the repair bill might run $1,500 or more for parts and labor. The parts required to replace a head gasket include not only the head gasket itself, but also all the other gaskets that have to be replaced to disassemble the top of the engine. This includes the intake and exhaust manifold gaskets, too, plus new cylinder head bolts if the application is a late model engine with non-reusable torque-to-yield (TTY) head bolts. “It’s often tempting to try to save a few pennies on off-brand gaskets,” according to Jim Daigle, product manager for Fel-Pro. “While these off-brand gaskets might look similar to branded products, they often do not feature the material characteristics and design enhancements required for trouble-free sealing.”

Depending on the mileage on the engine, additional parts should also be replaced at the same time. This might include the timing belt if the engine has an overhead cam (recommended replacement intervals for the belt range from 60,000 to 100,000 miles on most vehicles), the water pump, spark plugs and filters. The coolant should also be changed if it is more than 5 years old, or has more than 150,000 miles on it (long life coolants), or if it is more than 3 years old (older green formula coolant). If the head gasket caused an internal coolant leak, it’s possible the oxygen sensor(s) may have also been fouled by silicates in the antifreeze (if the cooling system was filled with older green formula coolant, or a hybrid HOAT or G-05 formula coolant).

What are the risks of reusing torque-to-yield (TTY) head bolts on late-model engines?

The risks are bolt breakage and uneven gasket loading or loss of torque that can cause a newly installed head gasket to leak. TTY head bolts are designed for one-time use because they stretch permanently once they are torqued down. This helps even out the clamping force of the cylinder head on the head gasket.

But if the bolts are reused, stretching them even further greatly increases the risk of the bolt breaking. Some replacement head gaskets come with new TTY head bolts, but others do not. If the bolts are not included, they should be included as an add-on sale. Many customers may not realize they should not reuse TTY head bolts. If an engine has conventional head bolts, it’s okay to reuse them — provided the bolts are in good condition and the bolts are not stretched.

Bolts can be cleaned, then lightly oiled and reused. Dirty or damaged threads, or failing to lubricate the bolts before they are installed can cause false torque readings when the bolts are tightened, which may allow the head gasket to leak.