SKYACTIV Technology: Ultra High-Compression, Direct Injection Engines Are Making Fuel-Economy Waves

The secret to Mazda’s fuel economy gains with its SKYACTIV-G engines is in its approach to combustion management. Diesel engines are typically about 30 percent more efficient than gasoline engines partly because of their significantly higher compression ratios (16:1 or higher for diesels versus 9:1 or 10:1 for most gasoline engines). Raising the compression ratio of a gasoline engine also improves its thermal efficiency, power output and fuel economy.

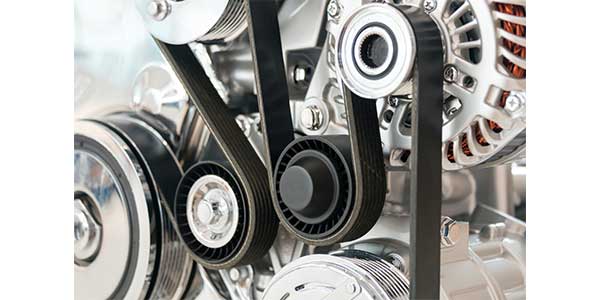

Automatic Belt Tension: Don’t Take It For Granted

Most late-model engines have serpentine belt drives for the engine-driven accessories. And, most people know that belts are a maintenance item and eventually have to be replaced. However, many don’t know the spring-loaded automatic tensioner that keeps a serpentine belt tight is also a wear item. Consequently, the automatic tensioner may also have to be replaced when the time comes to change the belt.

Oil Pump Diagnostics: Rebuild Or Replace?

Considering how important oil pressure is for all of these reasons, why would anyone take a chance on reusing a high-mileage oil pump when rebuilding an engine?

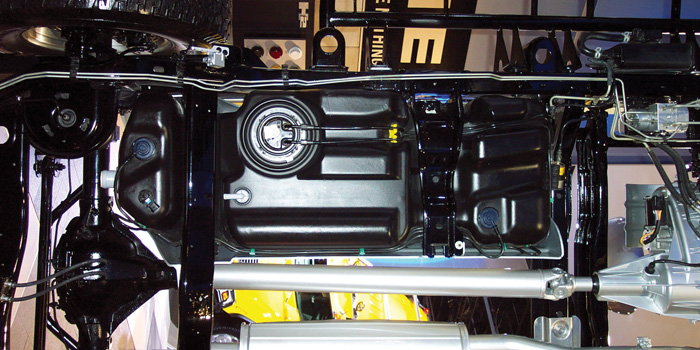

Inspecting Fuel Tanks For Filter Clogs

Any number of things may cause a fuel filter to plug up. One is a rusty fuel tank. Steel fuel tanks are coated inside with a special “tern” plating to resist corrosion. Over time, the protective plating can wear away and expose the steel, making it vulnerable to corrosion. Water in the fuel accelerates the process.

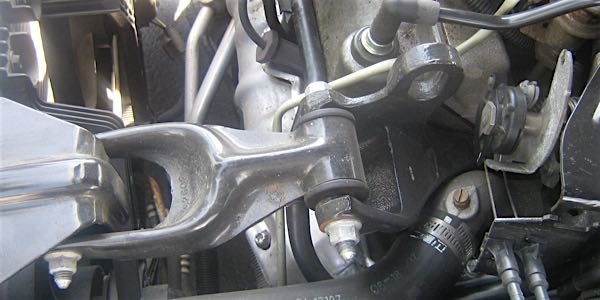

Motor Mount Replacement Tips

Back in the old days, spotting a failed motor mount was easy. The cooling fan hit the radiator shroud and the engine would move side-to-side as the engine was loaded. Today, it takes a little more time to spot a worn motor mount. Why? Because a modern motor mount might do more than just hold the engine in place.

Alternator Failures: Low Voltage To The Battery

One reason why alternators have a high failure rate is because they’re always working under a load. Generating electricity to recharge the battery, run the fuel pump, injectors and ignition system while powering all of the vehicle’s lights and electrical accessories places a substantial load on the alternator that generates a lot of internal heat.

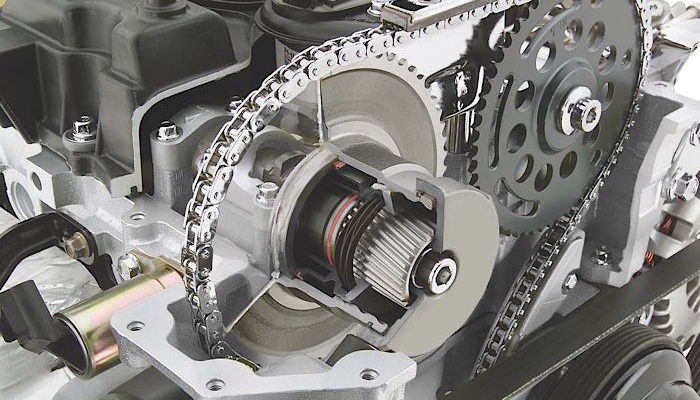

Variable Valve Timing

One of the ways automakers squeeze more horsepower and torque from an engine is by adding variable valve timing (VVT) to the valvetrain. A conventional camshaft has fixed valve lift, duration and timing; so, the grind is always a compromise between fuel economy, performance and emissions. But with VVT, duration, valve overlap and timing can be changed on the go to optimize engine performance at different RPM, loads and operating conditions.

Deposit Control Additives And Bad Gas

A buildup of carbon deposits inside the combustion chamber increases the risk of hot spots forming that may cause engine-damaging preignition. The hot spot ignites the fuel before the spark plug fires, causing a sharp rise in combustion pressure. Under extreme conditions (high rpm and load), preignition can burn a hole right through the top of a piston.

Power Window Regulator And Motor Service

Power windows are great as long as they roll up and down when commanded to do so. But sometimes a window may quit working for one reason or another. Sometimes the fault is electrical, such as a bad power window switch, a blown fuse, a bad relay or a loose or damaged wire. Other times, the fault is a bad window motor or a broken part in the window regulator mechanism that actually raises and lowers the glass.

Spark Plugs: Choosing A Heat Range

Choosing a set of racing spark plugs for a particular application is not as easy as it sounds because the plugs have to be closely matched to the application. Stock plugs are fine for stock applications and ordinary driving conditions. But when an engine is modified to make more power and is run under racing conditions, a lot of things change inside the combustion chamber.

Cylinder Head Design And Selection

Choosing the “right” cylinder heads for an engine build can make all the difference in an engine that delivers and one that falls short of its potential. Horsepower, torque and throttle response all depend on how well the cylinder heads, camshaft and induction system work together. Choose the right combination and you’ll build a winner. Choose the wrong combination and you’ll end up with a mismatch that never achieves what you set out to achieve.

Automotive Fuel Pumps Continue To Evolve

On most applications, the pump runs at a constant speed (typically 3,000 to 7,000 RPM depending on the design). However, on many newer vehicles, pump speed is controlled by the PCM and will vary depending on engine load and speed. The most common type of electric fuel pump today is the turbine style pump. An impeller ring with many small blades is attached to the electric motor inside the pump.