Hyundai has two four-cylinder engines that use a turbocharger. The Gamma and Theta turbocharged engines were introduced in 2010 for many Hyundai cars and trucks. These engines also have direct injection, which makes them even more efficient.

Knowing the basics of how all turbocharged systems work can serve you well in solving problems with turbo-equipped Hyundais. A good scan tool that can graph boost pressure and a smoke machine can also improve diagnostic procedures.

Oil Quality

The key to keeping the turbo (and more importantly the timing chain) healthy is the quality of oil and the frequency of oil changes. Since 2011, the owner’s manual specifies an ILSAC GF-4 oil with an API SM rating. But, there have been upgrades. ILACS GF-5 oils are available and API has issued SN and SN-Plus oils that can extend the life turbocharger, timing chain and even the high-pressure fuel pump.

Hyundai recommends that the oil and filter are changed between 3,000 to 5,000 miles, depending on how the vehicle is driven. Not changing the oil will cause the oil to form deposits in the turbocharger’s housing. These deposits will cause restrictions in the oil passages and the turbocharger to run hotter.

WGT Operation

The wastegate manages the flow of exhaust gases over the turbine. If the boost reaches a specific level, the gate opens and exhaust gases bypass the turbine. Depending on the engine, Hyundai can actuate the wastegate with a vacuum pressure pot or stepper motor. Both actuation methods have adjustment procedures.

The first-generation Gamma 1.6 turbocharged engine uses a pressure-actuated wastegate. A diaphragm working against a spring controls the wastegate. Vacuum pressure inside the actuator is controlled by a solenoid that receives a pulse-width modulated signal that is controlled by the ECM.

The Wastegate Solenoid Valve Control Solenoid Valve (WGT) controls the actuator that opens the bypass passage of the turbocharger turbine. In order to drop the turbine internal pressure, the ECM restricts the turbine rotation by opening the bypass passage.

There are alignment marks on the arm of the wastegate and housing. Lengthening and shortening the rod adjusts the wastegate. The actuator rod should move when a vacuum of -9.08 psi is applied to the actuator.

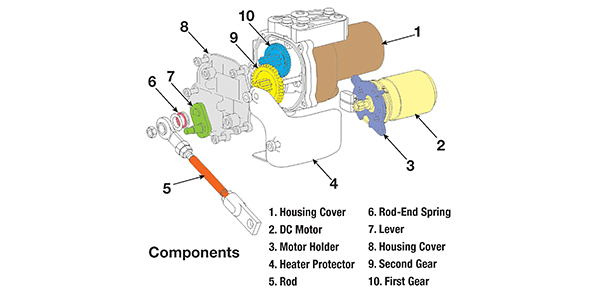

The 2.0 L GDI turbocharged Theta engine uses a stepper motor to open the wastegate. The Electric WGT (EWGAT) is installed on the turbocharger. The actuator consists of a DC motor that actuates the wastegate. Inside the unit is a two-step gear transmission that increases the torque of the motor.

The EWGAT has a position sensor that measures the voltage from the open stop to the closed stop. The voltage from the sensor is used to measure the position of the vane. The five-volt signal correlates with the amount of lift of the wastegate. The sensor output on a scan tool is used to adjust the rod. The adaption mode menu for the EWGAT needs to be activated. The target voltage is listed in the service information and can vary depending on the model and year. Turning the rod end clockwise will increase the voltage, and turning it counterclockwise will decrease the voltage.

Recirculation Valve Control (RVC)

Hyundai calls its blow-off or diverter valve a Recirculation Valve Control (RVC). An electronic solenoid valve that controls engine vacuum operates the RVC. The valve recirculates air back into the intake or air cleaner. The valve can be mounted on the charge pipe or, in the case of the first-generation Veloster, the valve is mounted on the intercooler.

Boost control is accomplished both with the wastegate and recirculation valve. More importantly, they work together so the desired boost pressure is achieved, while keeping the turbines spinning so that lag is minimized.

Codes for the valves and actuators are either electrical or they are generated because a command does not provide the desired result. Electrical codes typically indicate a circuit failure, or high or low voltages that indicate an open or high resistance for the solenoid’s circuit. Testing the circuit with meters and scopes is part of Hyundai’s diagnostic process.

The engine management system looks at several sensors, including the knock, air/fuel ratio and the boost sensors, to regulate the performance of the engine and turbocharger. Other inputs are used to determine if the boost levels are safe. If there is a malfunctioning sensor, the system will reduce boost pressures and go into a fail-safe mode.

Turbo Damage

One of the more vulnerable areas of any turbocharged engine is the exhaust manifold. Leaks around the gaskets and cracks in the manifold can lead to a loss of power and even oxygen sensor readings.

One item to check if you are dealing with lack of power complaint is the turbine’s compressor wheel. If the fins of the compressor are damaged, it can cause poor acceleration, low boost levels and noise. The damage can occur two ways. First, the turbo can ingest debris. With the wheel spinning in excess of 100,000 rpm, even the smallest rock or piece of metal is like a bullet. Second, the shaft bearings inside the turbo have enough endplay to cause the turbine to make contact with the housing.

You can expect to see a lot more turbos on Hyundai models. The new Stinger and Genesis models are using a twin-turbo V6 that has more than 300 hp.