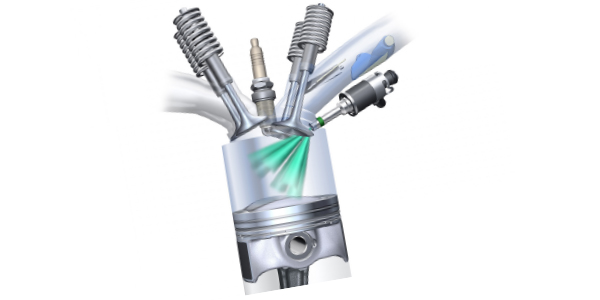

Mechanical constant stream fuel injection is the pinnacle of pure mechanical engineering. The mechanic setting up the system must optimize the amount of fuel for a given throttle position, rpm and engine load. By using different pumps, jets, linkages and metering block settings, it is possible to deliver the correct amount of fuel in large volumes for wide open throttle.

Mechanical fuel injection made its debut on airplanes during WWII. By not having a carburetor with floats and bowls, mechanical fuel-injected planes had an advantage during high- and low-G maneuvers. After the war, mechanical fuel injection on a drag, oval or road racecar was the sign of a serious machine.

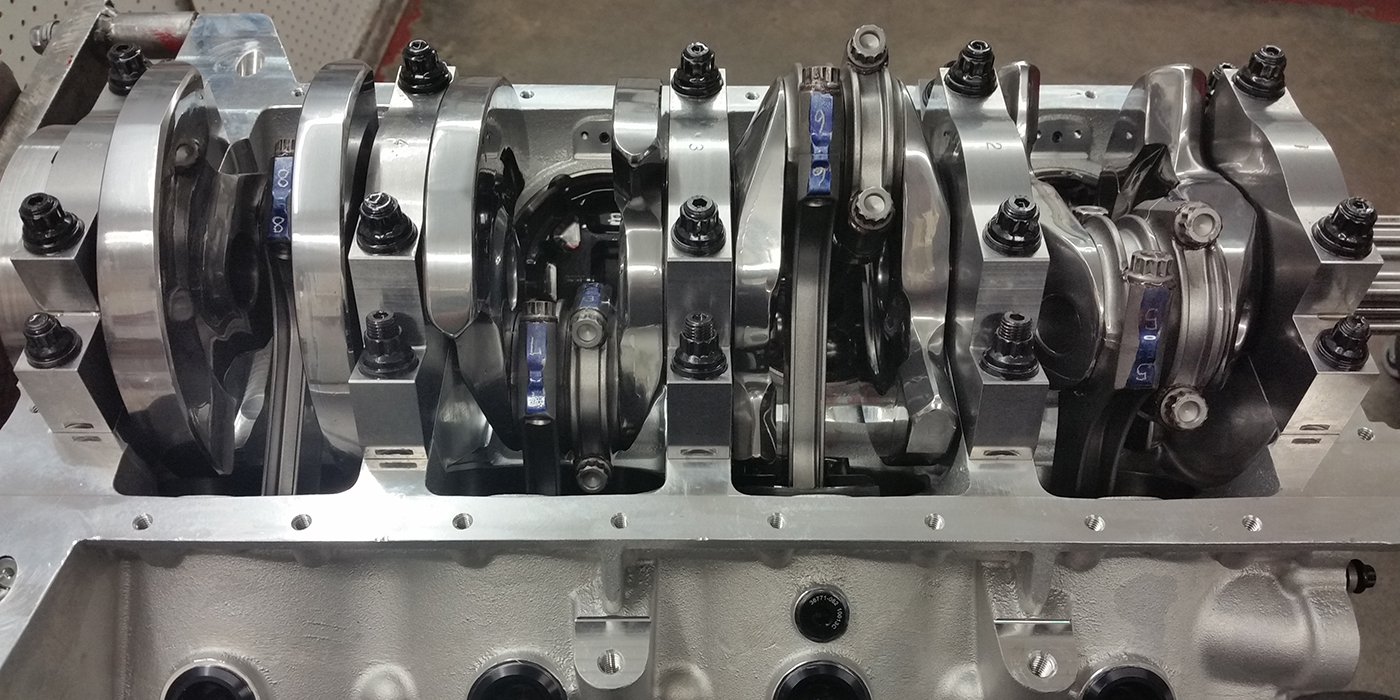

One of the masters of mechanical fuel injection is Jim Kinsler. The former GM R&D engineer was often loaned out to race teams owned by Smokey Yunick, Jim Hall and Roger Penske for clandestine racing operations that violated the no racing pact of 1955.

After GM, Kinsler started his own company selling electronic and mechanical fuel injection systems. Kinsler Fuel Injection has been in business for more than 40 years, and son James has started a new venture making racecar-inspired putters. Using the same CNC machines used to make custom intake manifolds, the Kinsler Raptor is designed to be flat at address, and the weight can be changed to suit the player’s putting stroke.