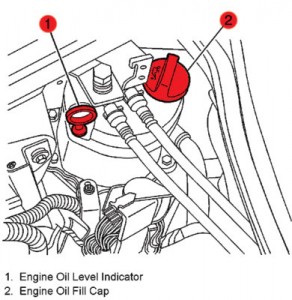

In order to get an accurate reading, the oil must be warm and the vehicle must be on level ground. A cold oil level in the dry sump tank may not indicate the correct amount of oil in the system.

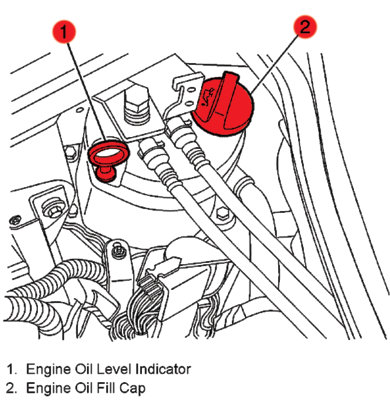

In order to get an accurate reading, the oil must be warm and the vehicle must be on level ground. A cold oil level in the dry sump tank may not indicate the correct amount of oil in the system.

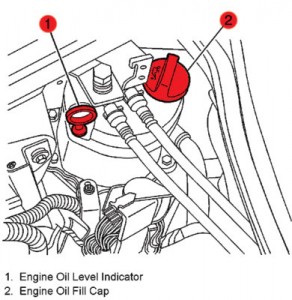

In order to get an accurate reading, the oil must be warm and the vehicle must be on level ground. A cold oil level in the dry sump tank may not indicate the correct amount of oil in the system.

In order to get an accurate reading, the oil must be warm and the vehicle must be on level ground. A cold oil level in the dry sump tank may not indicate the correct amount of oil in the system.

The area of contact between the lifters and cam lobes is the highest loaded surface inside an engine.

The basic function of a valve lifter is pretty simple. It sits on the camshaft and transfers the motions of the cam lobe up through the pushrods and rockers to open and close the valves. The size and shape of the cam lobe under the lifter (multiplied by the ratio of the rocker arms) determine valve lift and duration. As such, the lifter just follows the motions of the cam. But, it does play a role in valvetrain lash (clearance) and noise.

Many alternator problems turn out to be nothing more than a bad connection at the alternator or a bad wiring harness.

All-season coolant used inorganic acid technology and worked great for almost 30 years.

Why do ignition systems give technicians problems when diagnosing ignition-related misfires? The answer is that some technicians use tests that might give inconclusive results or do damage to the coil or drivers inside a module.

Servicing the serpentine belt on some vehicles is a tough task.

Here are six tips to use when diagnosing a vehicle with a dead battery.

As the timing chain wears, it can change the timing of the camshaft and crankshaft.

The primary cause of these problems is that fuel and added detergents are not hitting the back of the intake valves.

It is important to check the operation of the solenoids that control vacuum to the actuators.