Veyance Technologies, manufacturer of Goodyear Engineered Products, has announced the release of 175 new part numbers to its automotive aftermarket and heavy-duty product lines for the first quarter of 2012.

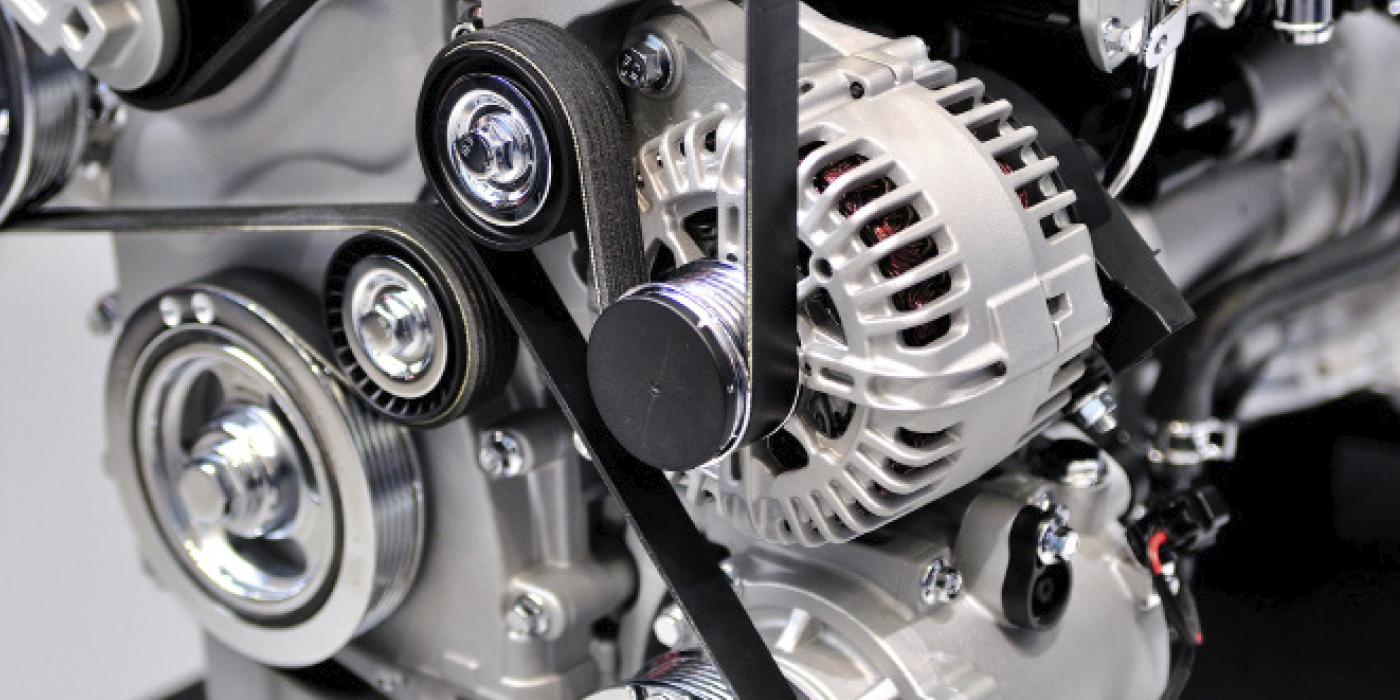

The company says these new additions provide even more extensive vehicle coverage for some of the brand’s most popular products, including:

• 76 molded heater and molded radiator hoses

• 50 air springs

• 20 timing belt component kits

• 17 overrunning alternator pulleys (OAPs)

• 8 tensioners

• 3 pulleys

• 1 timing belt

The company has added more than 800 part numbers since the beginning of 2011 as part of its concerted effort to expand coverage to more domestic and import vehicles.

“We’re thrilled to be able to introduce so many part numbers and better serve our customers,” said Tory Perren, marketing manager at Veyance Technologies. “Extending vehicle application coverage is one of our main priorities, and we plan to continue to invest in all of our product lines.”

“With the use of DataDrive, our market intelligence system, Veyance is able to anticipate the aftermarket’s needs and prepare for future trends, which gives us the ability to provide our customers with optimized inventories,” explained Perren. “It’s all about delivering the right parts to the right place on time."

For a full listing of the new product additions, contact your local Goodyear Engineered Products sales representative.