A technician without a scan tool today is like a dentist without a drill. You can’t get to the root cause of many problems because you lack the tools to do so.

Though some vehicles have diagnostic modes that can show fault codes and other diagnostic information via the instrument panel, climate control system or driver information display, most simply turn on the check engine light or another warning light when a problem occurs. So without a scan tool, there’s no way to tell what the problem might be, let alone make an accurate diagnosis of which sensor or other component may need to be replaced.

For simple powertrain and emissions-related diagnostics, you may think all you need is a basic OBD II code reader, entry-level scan tool or PC-based scanner software to read and clear fault codes. But a code by itself is not a diagnosis. It only tells you that a fault has occurred. The code does not tell you why the fault occurred, and in some cases, it doesn’t even tell you the sensor, circuit or component where the fault occurred. These include faults like P0300 random misfire codes, and P0171 and P0174 lean codes. Then there are codes like P0400 for the EGR system, P0420 for the catalytic converter and P0440 for the evaporative emission system that indicate something is amiss, but doesn’t tell you what to fix.

To diagnose these kinds of faults, you need a scan tool or scanner software that can also display OBD II system sensor data and other operating perimeters. The more information or “PIDs” the tool can display, the better. Of course, you have to know what you’re looking at and how to distinguish good values from bad values. That requires training and experience. But some of the better professional-level scan tools include guided diagnostics or capabilities that can flag bad data. Obviously, a scan tool that costs $200 won’t be in the same league as one that costs 10 or 20 times as much.

Investing in a Scan Tool or Scanner Software

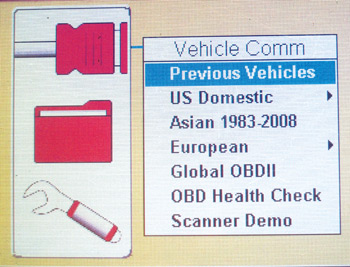

It’s a given that powertrain and emissions diagnostics require a high-end scan tool. But diagnostics today doesn’t end with powertrain and emissions. It reaches into almost every system on the vehicle. The antilock brake system, traction control system, stability control system, electronic steering, automatic climate control system, keyless entry system, etc. etc. etc. on late-model vehicles are electronically integrated and share data via the Controller Area Network (CAN) system. Consequently, a fault in what seems like an unrelated component may affect driveability or emissions. So you also need a scan tool or scanner software that can reach into every nook and cranny of the vehicle’s electronics, not just the OBD II system.

Factory scan tools are the best choice for this level of diagnostics, but factory scan tools are expensive and typically have limited capabilities for working on other vehicle makes and models. An aftermarket scan tool that comes with various software packages, therefore, provides more flexibility and wider coverage. Even so, many technicians feel they need both: an OEM scan tool or scanner software for performing advanced diagnostics on specific makes, and a universal scan tool for general diagnostics or for working on vehicles for which they do not have the OEM scan tool.

Most professional-level aftermarket scan tools are available with various software packages that can provide as much coverage as you think you can afford. If you rarely work on high-end European makes, there’s no need to buy the European software package. On the other hand, if your shop specializes in BMWs or Mercedes-Benz or another make, you want a scan tool or scanner software that provides as much data access and most of the self-test capabilities as the OEM scan tool.

Justifying the investment in a high-end scan tool or scanner software should be a no-brainer. How can you afford not to have this type of equipment if you expect to make a living fixing your customers’ vehicles? Not having the right scan tool or software can severely limit your ability to troubleshoot and repair driveability, emissions and all kinds of other electronic faults.

A professional-level scan tool with bidirectional capabilities (which are necessary to access and run the various self-tests that may be available on a vehicle) can set you back anywhere from $1,500 to $7,500 or more, depending on the package and options you buy.

As a rule, equipment suppliers typically offer a better price on a bundled scan tool package that includes various extras and options. In other words, you’ll probably save money in the long run by buying a more complete scan tool package than adding features and capabilities later.

Calculating the return on investment for a scan tool isn’t as straight forward as it is on other types of shop equipment such as a wheel balancer or alignment rack. For these other pieces of equipment, you can calculate their payback by dividing the cost of the equipment by the number of jobs performed. You can do the same with a scan tool if you have a flat fee for diagnostic time. But you also have to factor in the other things a scan tool allows you to do — such as not losing a job because you didn’t have the software to fix a customer’s vehicle.

You also get additional payback from the tool by using it to verify that problems have been eliminated after repairs have been made (which prevents expensive comebacks and unhappy customers), to check and verify emissions, and to perform various “relearn” functions that may be necessary after sensors or components have been replaced or electrical power has been lost due to a failed battery or battery disconnect.

Let’s say you spend $5,000 on a scan tool. If you use it six times a day, five days a week (you get Saturday and Sunday off), you’re using the tool 30 times a week or 1,560 times a year. Divide that by the price you paid for the tool, and your cost per use figures out to a little over $3 per job for the year. That’s peanuts compared to what parts and labor for most repairs cost today.

Software Updates

But there’s another cost that also has to be factored in: software updates. The software inside a scan tool gets stale rather quickly these days, and must be updated regularly. Every new model year brings with it more new fault codes, more new self-tests and more diagnostic capabilities. Vehicle technology is changing at an extremely rapid pace, so it is more important than ever to keep your scan tool up-to-date.

One aftermarket scan tool manufacturer said its latest software update adds 45,000 new fault codes and more than 1,500 new component function tests that were not available in its previous software version. Maybe you think you don’t need the latest update, and can get by with last year’s software. But there’s no way to know until you’re faced with a problem that may require a diagnostic self-test you can’t run because your scan tool doesn’t have the proper software to run the test. This includes things like resetting a steering wheel position sensor after an alignment or sensor replacement, performing a crank sensor relearn procedure on a vehicle that requires it after the sensor has been replaced, checking the operation of the EGR system on a diesel engine, reprogramming the TPMS system to recognize new tire pressure sensors, and so on.

Software updates may be available quarterly, every six months or yearly. Updates may be available online as downloads from the tool supplier, or available on a CD. Most significant updates are made on a yearly basis. The cost of the updated software will depend on the package and its capabilities, and whether you are a “loyal” subscriber who renews your software on a regular basis, or someone who skips a year or two before renewing.

For example, one aftermarket scan tool manufacturer charges loyal customers $895 for an annual software update for its high-end scan tool, but $1,195 for customers who have skipped a year or more. The software update for its mid-range scan tool runs $495 if you renew regularly, but $995 if you don’t.

Training

One other cost that needs to be factored into a high-end scan tool purchase is training. A new scan tool with lots of bells and whistles and advanced diagnostics may never be used to its full potential if nobody knows how to use all of its features. Graphing and comparing sensor waveforms is a cool feature to have, but do you know what you’re looking at? Some type of advanced training, therefore, is absolutely essential to get the most out of any scan tool. Many equipment suppliers as well as vo-tech schools offer scan tool courses that can help you learn how to use your equipment to its fullest potential. These include online e-courses and web clinics, many of which are free or available at minimal cost. The International Automotive Technician’s Network (www.iatn.net) is another good source of information, including its vast waveform library.

In conclusion, buying a professional-grade scan tool and keeping it up-to-date are unavoidable costs of doing business. Like hand tools, you need the right scan tool and software to efficiently diagnose and repair today’s vehicles.