Applicability: 2006-’09 Yaris

Some customers may experience multiple warning lights illuminated, vehicle not shifting from park to drive and other accessories becoming inoperative after the vehicle has cold soaked in sub-freezing (below 14° F [-10° C]) ambient air temperatures. A new relay has been made available to improve this condition. Use the following procedure to address this concern.

Production Change Information

Body Type Production Change Effective VIN

3-Door H/B JTDJT903#95232203

5-Door H/B JTDKT903#95232205

4-Door Sedan JTDBT903#91312181

JTDBT903#94049676

*Note the 11th digit of the VIN; this indicates the plant in which the vehicle was built. Match the 11th digit, then determine if the vehicle is applicable by the six digits after the plant number.

2009 model-year Yaris vehicles produced before the production change effective VINs shown.

Repair Procedure:

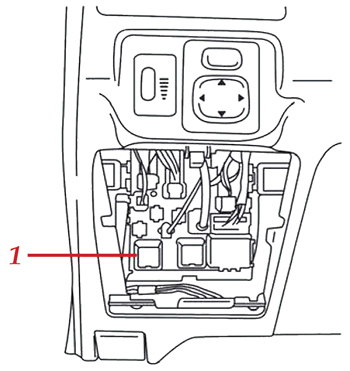

1. Locate the instrument panel Junction Block No. 1 located in the Instrument Panel (as shown in Fig. 1).

2. Remove the relay and verify the part number located on the side of the relay.

a. If the part number is 90987-02025 or 90987-02030, replace the relay with the countermeasure relay P/N 90987-02031.

b. If the part number is 90987-02031, then diagnose the specific conditions reported by the customer per the repair manual.

3. Connect TIS Techstream and clear any stored DTCs.

Courtesy of ALLDATA.