By adjusting the fuel pressure you are looking for maximum power from your new high performance engine and this will take some trial and error to achieve. To make the adjustment you will need the following tools: A fuel pressure gauge that will screw onto your Schrader Valve on your fuel rail and a small wrench to turn the screw on the regulator.

By adjusting the fuel pressure you are looking for maximum power from your new high performance engine and this will take some trial and error to achieve. To make the adjustment you will need the following tools: A fuel pressure gauge that will screw onto your Schrader Valve on your fuel rail and a small wrench to turn the screw on the regulator.

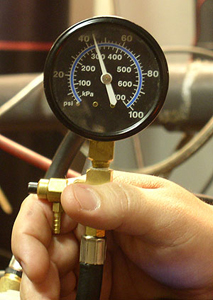

Step #1 – You will need to screw the fuel pressure gauge onto the Schrader Valve that is located on your fuel rail, (see Figure 1) make sure that it is tight to avoid any leaks and or fires. Once the gauge is installed turn the ignition key to the on position and check for leaks at the Schrader Valve.

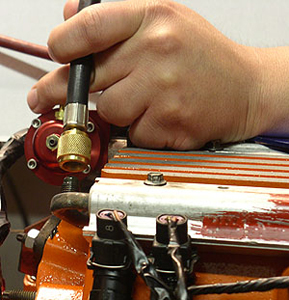

Step #2 – Start the engine and let the idle level off and then disconnect the vacuum line that goes to the regulator (see Figure 2), make sure that you plug the rubber vacuum line so it does not leak vacuum while you are making the adjustment, (you only care about the fuel pressure reading with the vacuum line disconnected at idle).

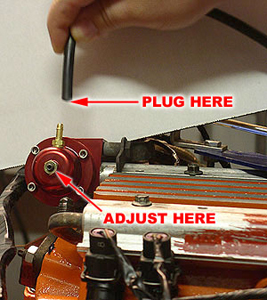

Step #3 – Take the reading and make the adjustment to 46 lbs. (see Figure 3).

Step #4 – You will need to drive the vehicle and take notes as to how it is performing, I recommend driving it for a little while so you know exactly how the engine and vehicle react. Once you are familiar with the engines performance adjust the fuel pressure up 2 lbs. at a time taking notes as to the performance gain or loss and finally end your adjustment at max power.

– Tech Tip is courtesy of Golen Engine Service.