Even though I’ve spent a lifetime repairing the electrical nightmares that come into my shop, it still has its surprises. These days it’s not only the wiring, but some of the results I see from the scanners that can be just as unexpected.

Even though I’ve spent a lifetime repairing the electrical nightmares that come into my shop, it still has its surprises. These days it’s not only the wiring, but some of the results I see from the scanners that can be just as unexpected.

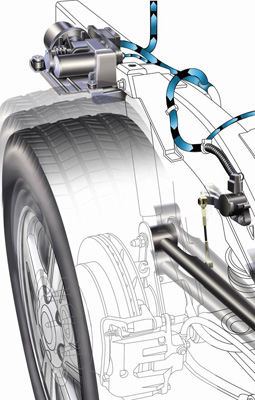

My buddy Tom’s 2005 Cadillac Escalade EXT was having some problems. It’s a well kept, clean and in great shape ride. The suspension system was sending the driver its little notice across the dash message banner, “Suspension System Service Needed.”

“Sure, bring it in Tom. I’ll throw it on the scanner and see what’s going on,” I told my old pal.

I grabbed the Tech 2 with the CAN unit hooked up to it and headed to the car. Only one code, C0660, was stored “Level Control Exhaust Valve.”

“Ouch Tom, that’s going to mean a new pump unit because, as far as I know, the valve isn’t something that is sold separately,” I told him.“But let’s run the diagnostic test and make sure.”

Tom and I are old friends and he gets a kick out of watching the technical wizardry of the scanners and the processes we as technicians go through to make the repairs on these cars. He’s known me for so long he, knows I’m not one to skip or guess at the repair. I like to know that what I’m doing is correct and as precise as it can be.

With Tom watching over my shoulder (as he always does), I pulled up the diagnostics for the code on the shop PC. I printed a copy to carry out to the car and Tom read step one of the diagnostics out loud.

“Read the codes, check for anything that looks out of place … stuff like that, and verify complaint,” I told him.

“Well, what do you think?” he wanted to know.

“Let’s go to step two,” I said.

1. Install a scan tool.

2. Turn on Ignition, with the engine off.

3. With the scan tool, command the exhaust solenoid ON and OFF.

Does the exhaust solenoid valve turn ON and OFF with each command? Yes or No.

After several years using a scanner, it’s not uncommon to activate a solenoid or a component this way. A lot of times I use this same test to check transmission shift solenoids, or turn on a blower motor, maybe even activate the A/C compressor. There are so many components that can be activated this way, and it makes the job a lot easier once you get the hang of using the scanner. This was no different, or was it?

I found the section on the scanner and hit the ON button. Instead of a “click” or a constant OFF on the screen information, I got an error message — “No communication with Suspension Module.”

I tried it several times, same results every time. Tom, looking a little puzzled, said “It should have activated the solenoid or something, right?”

“What was the question on two again, Tom?” I asked, since he was holding the paperwork.

“It wants to know Yes, see Diagnostic Aids, or NO, go to step three,” Tom reads, “but it doesn’t say what to do if there is no communication.”

Normally, if I was activating a solenoid, I would listen for that “click.” If I didn’t hear the “click,” I would read the screen to see if the activation was accepted, and see if it had switched from On to OFF, but I’ve never seen the scanner go from perfect communication to “no communication” as soon as I tried to activate a solenoid.

Just to double-check things, I wanted to activate the compressor from the scanner since it was on the same page as the exhaust solenoid. I tried it and got the same result … “No Comm.”

OK, for all you techies out there, before you read the rest of this, what’s your first idea as to what’s going on with this vehicle? Is it a buss line problem, a suspension module problem, or is it merely the exhaust valve? No fair if you’ve already run across this.

Time to take your guess. OK, now don’t change your answer. Here we go with the rest of the story.

I took a chance, since I had some sort of communication with the module, I thought I might as well look at the wiring diagram and see if I could activate the valve and the compressor directly at the module. On pin #B5 (dark blue) of the module was the ground signal from the module to the exhaust valve. I grounded the lead; “click” the valve worked (and that was what the code was for). I then found the ground lead that activated the compressor relay, lead #A10 (light blue). It too worked.

That doesn’t mean that it’s working back there at the compressor. Just because I turned them on is no guarantee it’s pumping air into the shocks. When I’m not 100% sure, I get a second opinion. I’m thinking it was the module, and if it is the module, we’ll have to reprogram it. But, before I condemn the module, I think we should get that second opinion.

Since I didn’t sound sure of myself, Tom said he would run over to the dealer and see what they said. I was concerned that my Tech 2 might be the problem. I couldn’t be sure without finding someone else with the same equipment and do the same test.

Not only was it for Tom’s Escalade, but also for my sake. I wanted to be sure my scanner was working OK. It wasn’t even an hour later, and he was back over to my shop.

“They said it needs a compressor assembly and both shocks because they said the shocks are leaking,” explained Tom

“Has it ever dropped since the pump stopped working?,” I inquired.

“No, never has,” said Tom.

“I don’t think you need shocks, but I’ll have to lean towards the pump.” I said.

But, that doesn’t explain the “No Comm.” We both knew the code said the exhaust solenoid was out. Two different scanners had the same conclusion.

I’m sure they’re more familiar with it than I am. Sounds like we should start with a compressor. I’m not ruling out the module yet, and I’m very positive that you don’t need shocks. But, there might be some feedback signal that the test isn’t telling me about that might be the cause of the “No comm.” Let’s change the compressor.

“Start it up Tom.”

As soon as he turned the key, he knew it was fixed, the suspension message was gone, and the dash was back to normal.

“Tom, let’s back it out of the way of the lift and try the scanner again,” I said

We did just that, and wouldn’t you know it, each and every time I activated the solenoid or the compressor, it came on. The code was no longer current, but was in the history file. I cleared the codes and ran thru the test again, all clear.

OK, what did you think it was? How many guessed that it wasn’t the exhaust valve that was bad, even thought that was the code?

What it turned out to be was the pressure sensor mounted on the pump. When the info didn’t make it to the module, the module shuts down any and all operation, including the diagnostic scanner capabilities. I wouldn’t have believed it myself, but I watched it happen right in front of me.

So, if you run across a suspension system on one of these Escalades and the test asks to activate the exhaust solenoid, and the scanner says “No Comm,” check that pressure sensor for its reference return signal. You can bet I made a note about this one.