Diagnosing Crankshaft Position Sensors

Modern engines need to know the position of the crankshaft and camshafts.

ECM Damage

Engineers have devised two strategies that can be called the “immune system” for the electrical system.

Engine Control Modules (VIDEO)

Accurate diagnosis of any suspected ECM-related fault is important. This video is sponsored by The Group Training Academy.

ECM/PCM Communication Issues (VIDEO)

Before you swap out a module that won’t communicate, do a few simple inspections. Sponsored by The Group Training Academy.

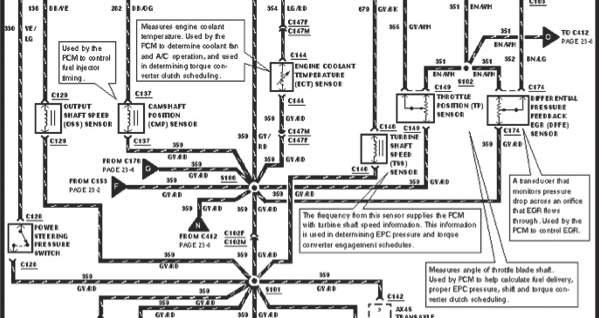

Understanding Engine Control Module No Communication Issues

You plug in your diagnostic scanner or code reader, only to find out that you cannot communicate with the PCM. Bad PCM Right? Not necessarily!

Computer-Controlled, ‘Smart’ Charging System Strategies: Why Volts Are Smart, But Amps Are Smarter

When diagnosing a charging system on any modern import, think “smart.” I learned this lesson several decades ago when repairing a cranking, no-start condition on a 1989 Honda Civic, which was equipped with one of the first “smart” charging systems. After verifying fuse continuity, I discovered that excessively high charging voltage had destroyed the Honda’s Engine Control Module (ECM).

ECM Diagnostics: Troubleshooting P1518 Codes

ECM diagnostics can be a challenge because you often find yourself working after the fact. As described in the July 2015 issue of Underhood Service (“The 1,300-Mile Test Drive”), a seemingly routine loss of power and a no-cranking, no-instrument cluster, no-scan-tool communication complaint on a 2003 GMC Yukon, VIN Z 5.3-liter flex fuel engine turned out to be a major Diagnostic Dilemma.

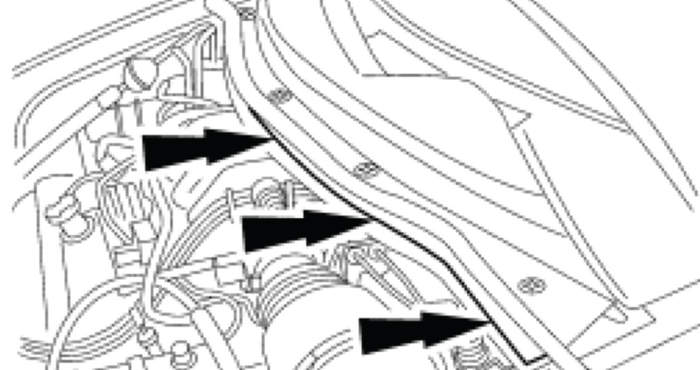

Ford: Driveability issues due to water in the PCM

Some 1999-2003 Windstar and 2004-’07 Freestar /Monterey vehicles built prior to June 22, 2006, may exhibit engine/transmission driveability issues due to water entering the powertrain control module (PCM) or transaxle vent. The water leakage may be due to the PCM connector cover not seating completely and water leaking down from the cowl panel grille (cowl

Pulling Codes: Signal No Longer Detected, The Story of Code P0340

This article will document the infamous P0340 code — Camshaft Position Sensor Circuit Malfunction. This is a code that involves the CMP signal, and, in many situations, one may be tempted to replace the sensor right away. This article will attempt to provide a game plan of attack. It’s always wise to start with a

Pinning Down Intermittent Malfunctions On OBD II Vehicles

Although post-1996 OBD II powertrain control modules (PCMs) are generally very reliable, we’re beginning to see more failures because the average age of our national vehicle fleet has now increased to about 11.5 years. Technically speaking, the PCM should store a DTC indicating some type of internal malfunction. But, in the real world, if your scan tool indicates “no communication” and asks if the ignition switch has been turned on, you obviously have a communications problem.

The Cracked Plate Coincidence: Uncovering An Uncommon Flex Plate Issue Twice In One Week

It never ceases to amaze me when I see certain types of problems in rapid succession of one another and then not see them again for months or even years. This column is dedicated to one such occurrence. Within a week of each other, two different vehicles came into my shop with cracked flex plates. While I have seen flex plates crack throughout my career, it is not a common scenario.

Snap Test: MAF Sensor Diagnostics

You’d think a service light would be the first indicator of a mass air flow (MAF) sensor problem, but there are times a problem develops with the MAF and no service light comes on. Scott “Gonzo” Weaver explains how poor idle, loss of performance, sluggish performance and even stalling are all associated with a failing MAF sensor.