This article will document the infamous P0340 code — Camshaft Position Sensor Circuit Malfunction. This is a code that involves the CMP signal, and, in many situations, one may be tempted to replace the sensor right away. This article will attempt to provide a game plan of attack.

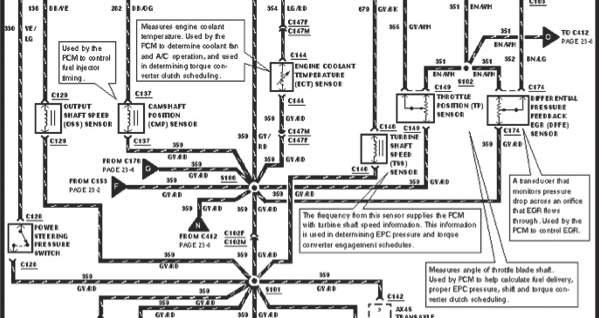

It’s always wise to start with a schematic of the system you are working on. See Figure 1.

Our subject vehicle is a 1999 Ford Windstar. The camshaft signal on this vehicle is used per the PCM to control injector timing. This vehicle has a rough cold start, but does start immediately. It appears to have multiple cylinders that are misfiring.

Our first step is to verify the complaint by checking the system with the EASE software, a PC-based system. It confirms we have a P0340 stored in memory. Let’s review the freeze-frame data and misfire data. See Figure 2.

Freeze-Frame and Misfire Data:

Engine Coolant Temperature: 45°

RPM: 1,854

Fuel System Status: closed loop

Total Fuel Trim Bank 1 (ST+LT): 15.59%

Total Fuel Trim Bank 2 (ST+LT): 8.64%

Vehicle speed: 0 mph.

The freeze-frame data shows that each bank has a tendency to run lean. A gas analysis is performed to confirm what we suspect. Review the following five-gas analysis code software data screen (Figure 3).

The gas analysis shows that the vehicle exhibits an optimum air/fuel ratio. It’s very difficult to see the fault per this five-gas analysis. A test drive was performed on the vehicle to gather additional data, and the snapshot showed that there was indeed misfire activity at times. See Figure 4.

A valuable clue soon surfaced; the cam sensor synchronizer was making a squealing noise. At times it was very noticeable, but at other times you could hear only a very slight noise.

The cam sensor was then scoped (Figure 5). The following pattern (Figure 6) is what we saw.

The pattern in Figure 7 appears to be good, but we have learned over the years to always wait to see if there is more to the story. Our patience pays off; we start to see what the problem may be. SeeFigure 8.

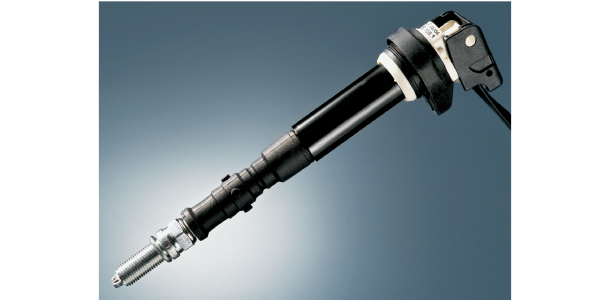

The cam sensor was then taken out for a visual inspection (Figure 9). It was found that the cam sensor synchronizer was very hard to turn.

The cam sensor synchronizer was replaced and the driveability problem was resolved.

This Pulling Codes case is now closed.

Want More on Ford Engine Performance?

Want More on Ford Engine Performance?

More than any other manufacturer, Ford has reinvented itself in the last decade. While many of the traditional services are now obsolete, the new Ford emissions and engine management systems create some great diagnosis and repair opportunities.

In Automotive Video Inc.’s Ford Engine Performance video (LBT-256), Wally Mouradian provides the training techs are looking for to give them the diagnostic edge, showing how to fix these cars with the least amount of effort.

Included:

• Ignition Primary, Secondary, Control & Current Tests

• Distributor, DIS, & COP Ignition Systems

• Fuel Pressurization & Injection

• Returnless Fuel Systems

• Adaptive Fuel Control

• Four Problem Areas: Fuel, Ignition, Mechanical, Air

• Rear Fuel Trim and Intake Air Measurement.

Take diagnostic time down to minutes while understanding PIDs and where they come from. The video also covers older and newer methods to diagnosing vehicles quicker, as well as how to eliminate the four problem areas to pinpoint the issue.

Runtime: 2.25 hours; a 400-page ATG manual is included.

Visit auto-video.com.