Models

2016-2018 Ford Explorer build in Chicago Assembly Plant from 9/19/2014-12/1/2017

Reference Number: 21N01

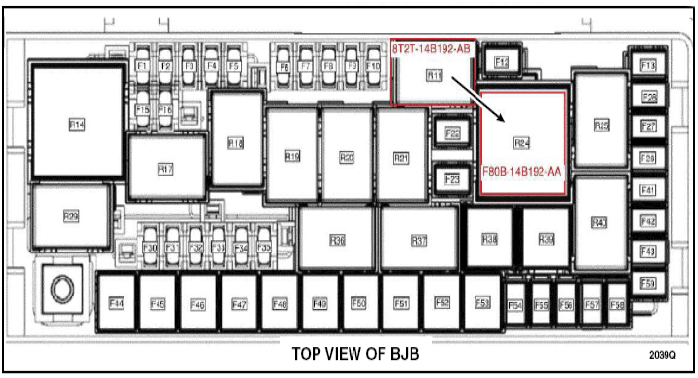

After extended idling, the high-speed cooling fan relay may fail in some of the affected vehicles. A failure will cause the fan to either continuously run or never turn on. A continuously running fan will increase the temperature of the relay’s connections (terminals) to beyond their design maximum. This may eventually create an electrical arc which heats and damages the relay terminals. Customers may experience a drained battery and a non-functional or even a melted/burned high-speed cooling fan relay inside the battery junction box (BJB). A damaged non-functional relay, causing the fan to never turn on may lead to engine overheating at idle.

Service Action

Dealers are to replace (splice) the four affected high-speed cooling fan relay terminals in the BJB and reroute the new terminals to a new larger relay. This service must be performed on all affected vehicles at no charge to the vehicle owner. Detailed repair instructions can be found in the TSB. This program provides a no-cost, one-time repair (if needed) to the high-speed cooling fan relay and respective electrical terminals, if affected, to 10 years of service or 150,000 miles from the warranty start date of the vehicle. This is a one-time repair program. If a vehicle has already exceeded either the time or mileage limits, this no-cost, one-time repair will last through August 31, 2022.

Program eligibility is automatically transferred to subsequent owners.