Fuel pressure can be checked by attaching a gauge to the Schrader valve fitting on the fuel injector rail, or by teeing the gauge into the fuel supply line if the fuel system lacks a test fitting.

The operating pressure of the fuel system must be within the range specified by the vehicle manufacturer. The numbers will typically read 5 to 9 PSI lower when the engine is idling than when the engine is off with the key on. Some vehicle manufacturers only list KOEO (Key On Engine Off) fuel pressure specs, while others also list the pressure specs for when the engine is running.

The volume of fuel delivered by the fuel pump is also important, because a weak pump may generate enough pressure to read normally at idle, but not keep up with the engine’s fuel requirements at higher speeds. This may cause a loss of power at highway speeds or when accelerating hard.

“A dirty or clogged fuel strainer indicates that contaminants within the fuel tank are impeding fuel flow and might have damaged the pump,” said Jeff Richardson, product manager, Carter Fuel Delivery Products. “It is important to also inspect the fuel filter for clogging, which can cut off fuel supply to the engine.”

A good fuel pump should usually deliver about a pint of fuel in 15 seconds (half a gallon per minute), but some engines need more than this. Fuel flow can be measured by disconnecting the fuel line from the injector fuel rail and routing it into a container, then energizing the pump.

A more accurate means of measuring fuel delivery is to connect a fuel flow meter to the fuel system. The meter has a floating ball that indicates fuel flow in gallons per minute (gpm).

A “good” reading on most applications would typically be 0.3 to 0.7 gpm. The flow meter can be hooked up to the supply line that runs to the fuel rail to measure flow.

Why do fuel injected cars use electric fuel pumps instead of mechanical fuel pumps?

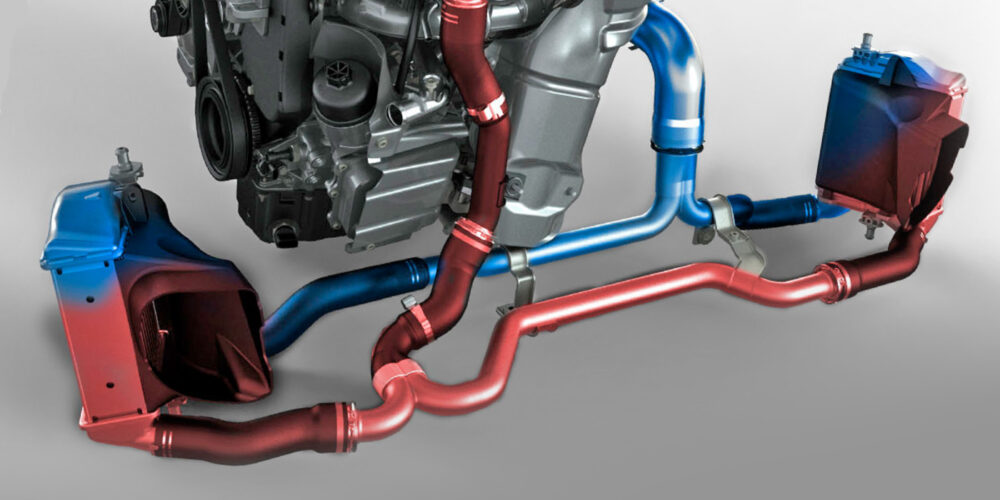

Because electronic fuel injection (EFI) requires a higher fuel system operating pressure than a carburetor (35 to 80 PSI versus 4 to 6 PSI). An electric pump also provides instant pressure to the injectors when the key is turned on (something a mechanical pump can’t do until the engine is cranked), and the speed and flow rate of an electric can be varied electronically to match the engine’s fuel needs.

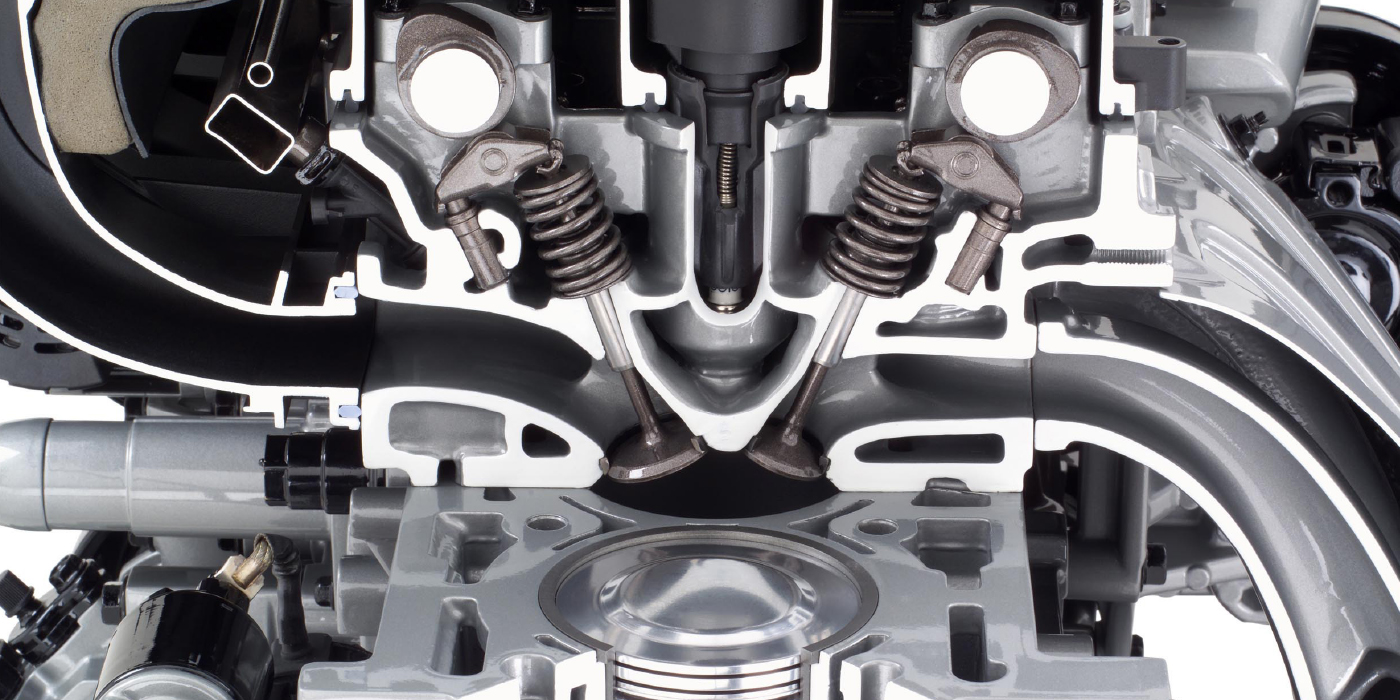

On an older engine with a carburetor, vacuum created in the intake manifold by the pumping action of the pistons pulls fuel from the carburetor into the engine. With fuel injection, fuel is sprayed into the intake ports under high pressure.

The amount of pressure behind the injectors is critical for proper fuel mixing and atomization, so low fuel pressure (or too much fuel pressure) can upset the air/fuel mixture and cause driveability and emissions problems. Fuel pressure is usually regulated by a mechanical regulator on the injector fuel rail. On “returnless” EFI systems, the pressure regulator is mounted on the fuel pump assembly in the fuel tank.