If front wheel speed sensor diagnosis leads to replacement of the sensor with a related DTC, do not replace the complete hub assembly. A front wheel speed sensor is available for individual installation.

Affected Vehicles:

• 2002.7-’03 Axiom (UP), 2WD models.

• 2002-’03 Rodeo (UE) and Rodeo Sport (UA), 2WD models.

Service Procedure:

1. Diagnose the speed sensor according to the “Brake Control System” section in the service manual.

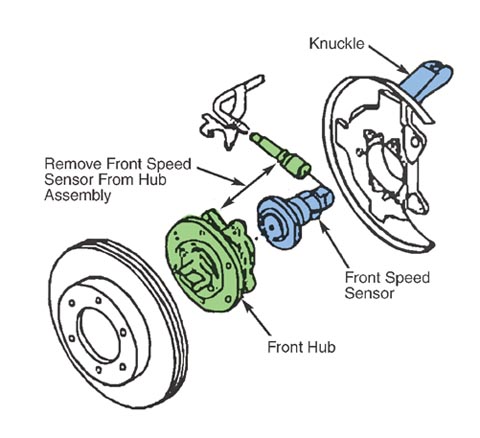

2. Remove the front hub assembly from the knuckle. Refer to the “Front Hub and Disc” section of the service manual. See Fig. 1.

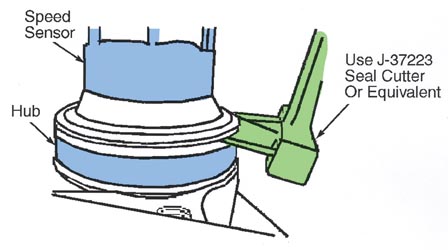

3. Insert seal cutter J-37223 between the hub mating surface and remove the speed sensor from the hub. See Fig. 2.

Note: Pay careful attention not to damage the sensor rotor and hub mating surface. Do not allow debris to enter the hub housing.

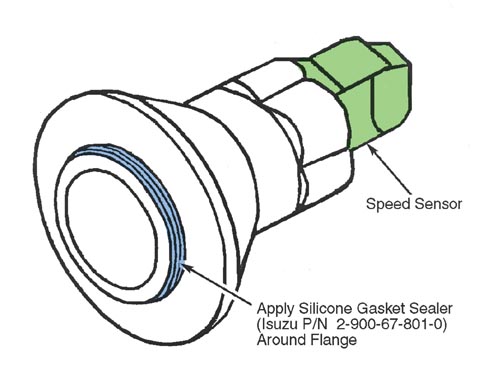

4. Apply silicone gasket sealer, Isuzu P/N 2-900-67-801-0, around the flange surface. See Fig. 3.

Note: Do not allow excess silicone and/or debris to enter the sensor housing.

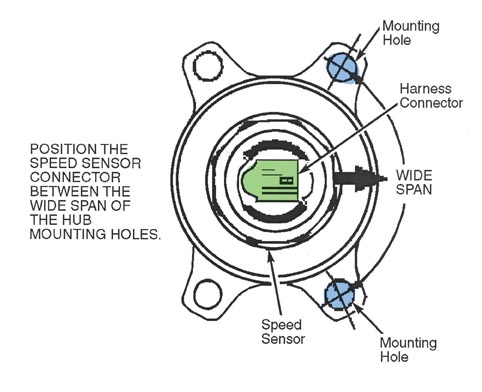

5. Position the speed sensor on the hub as shown in Fig. 4.

6. Place the hub assembly and speed sensor face down on the J-39825 bearing remover. Using a hydraulic press, press down until the hub and speed sensor are fully mated, applying 1.5 tons.

Note: To avoid speed sensor breakage, do not use excessive force when pressing the sensor into place.

7. To reinstall the front hub assembly to the knuckle, refer to the “Front Hub and Disc” section of the service manual.

Technical service bulletin courtesy of Mitchell 1.

For additional information, visit www.mitchell1.com.