By Gene Markel

Contributing Editor

If the engine quits at 60 mph, you have a chance of getting off the road safely. If a ball joint quits, you have a chance of crashing off the road.

The ball joint is one moveable part of a control arm assembly. The control arm bushings are just as important as the ball joint – if the ball joint is worn, chances are the bushings are just as worn. In the case of a strut suspension, the upper mount can receive as much wear as the ball joint.

The shock absorber is also an important component in the stability of the suspension system. If the shock absorber is out of oil, there is no damping.

There are specific types of ball joints for the different types of suspensions. Read on to learn more about the ball joint and its construction, types, wear and inspection.

Suspensions

MacPherson Strut: The strut and coil over spring requires a follower-type ball joint lower control arm.

Short Long Arm (SLA): On this type of suspension with the spring connected to the lower control arm, a loaded lower ball joint and follower upper ball joint are typically used. Or, if the spring is connected to the upper control arm, a follower on the lower ball joint and loaded upper ball joint are commonly used.

If you use a prybar and brute strength, your inspection could be influenced by the bushings. The control arm of an SLA or strut type suspension will have two bushings to allow the arm to move in a vertical motion and a ball joint to hold the steering knuckle. The ball joint also allows the steering linkage to turn the steering knuckle.

The bushings are made of rubber or an elastomer such as polyurethane. The purpose of the bushing is to isolate the control arm from the chassis of the vehicle in order to reduce vehicle noise vibration and harshness (NVH). The bushings absorb road shock by compressing and twisting. Rubber bushings are normally used as original equipment applications. Polyurethane bushings are used in performance applications and normally result in an increase of NVH.

The bushings are made of rubber or an elastomer such as polyurethane. The purpose of the bushing is to isolate the control arm from the chassis of the vehicle in order to reduce vehicle noise vibration and harshness (NVH). The bushings absorb road shock by compressing and twisting. Rubber bushings are normally used as original equipment applications. Polyurethane bushings are used in performance applications and normally result in an increase of NVH.

Types of Ball Joints

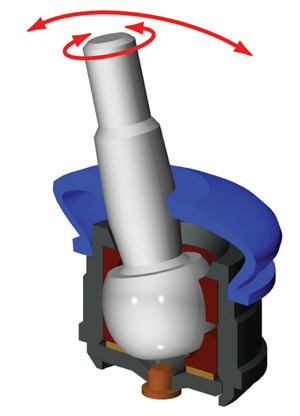

A loaded joint is designed to support the weight of the vehicle and a follower joint that positions the control arm or strut assembly.

A lower control arm that is connected to the spring uses a loaded ball joint to connect the steering knuckle to the upper control arm follower ball joint for a SLA suspension. The ball joint also allows the steering linkage to rotate the steering knuckle.

Follower ball joints are used in strut suspensions to connect the lower control arm, steering knuckle and the strut. The upper strut mount assembly usually contains a thrust-type bearing to support the weight of the vehicle and allow the steering linkage to rotate the strut and steering knuckle.

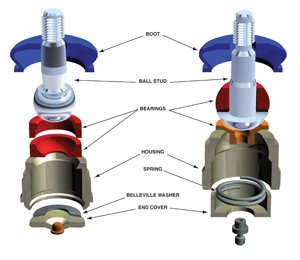

A ball joint is made up of a housing, ball stud, bearings, end cover and Belleville washer or spring. A Belleville washer is a conical-shaped spring designed to be loaded in the axial direction. The joint is attached to a control arm by pressing the joint into the arm or riveting the joint to the arm. If the joint is pressed into the arm, it will require a special tool to remove the old joint and install the new one.

Failed pressed joints can be difficult to remove because of corrosion between the control arm and joint. This is especially true where a steel ball joint housing is pressed into an aluminum control arm. When the joint is riveted to the control arm the rivets are drilled out or cut with an air chisel. The new joint is replaced using bolts and locking nuts.

Failed pressed joints can be difficult to remove because of corrosion between the control arm and joint. This is especially true where a steel ball joint housing is pressed into an aluminum control arm. When the joint is riveted to the control arm the rivets are drilled out or cut with an air chisel. The new joint is replaced using bolts and locking nuts.

Ball Joint Wear

Some ball joints that have a grease fitting use the fitting as a wear indicator. If a grease gun will not couple to the fitting, the joint needs to be replaced. As the joint wears, the Belleville washer or spring ensures the required tension on the bearings to maintain zero axial endplay as the control arms move. Lateral wear causes the ball stud to move inside the bearing. It can affect camber and tire wear. The Belleville washer or spring will not compensate for lateral wear.

Inspection

To check a loaded ball joint, place a jack or jack stand under the lower control arm to support the weight of the vehicle. Attach a dial indicator to the lower control arm and place the dial in a vertical position to measure axial runout at the steering knuckle. In the case of an all-wheel-drive front ride strut or independent RWD, it may be necessary to mount the dial at the CV joint. Moving the steering knuckle can check lateral runout.

For a SLA suspension that has the coil spring over the top arm, the upper joint is loaded. To check the joint, the upper control arm is supported to unload the joint. If the ball joint has a built-in wear indicator, joint play should be checked with the vehicle on its wheels.

To check a follower-type joint, the Belleville washer or spring is loaded or compressed to check for axial end play. For a strut-type suspension, place a jack stand under the cradle to allow the strut to fully extend. Attach the dial indicator clamp to the lower control arm and place the dial in a vertical position to measure axial runout at the steering knuckle. Place a jack under the ball joint and load the joint by raising the jack. Turn the steering wheel and observe the ball joint to check lateral runout.

For a SLA suspension, the upper control arm can be blocked and the joint can be compressed. Attach a dial indicator to the steering knuckle and place it in a vertical or parallel position to measure axial runout at the lower control arm. Moving the steering knuckle can check lateral runout.

The Big Picture

There are specifications for alignment, ride height and ball joint end play; the overall condition of the chassis is important to the safety and performance of the vehicle.

In the area of safety, it is a good practice to cover your assets. Try to convince the owner that it’s important to correct all of the conditions that could cause the vehicle not to perform safely. If this is not possible, make sure all conditions affecting safety that are not repaired at that time are made a part of the repair order, and attach a disclaimer.