Customers with an affected vehicle may complain of a clunk or squeak from the rear suspension when going over rough or bumpy roads.

Applies To:

• 1988-2000 Civic – All

• 1997-2001 CR-V – All

• 1993-’97 Del Sol – All

Probable Cause:

Broken rear trailing arm bushing(s).

Corrective Action:

Replace the rear trailing arm bushing(s).

Parts Information:

Rear Trailing Arm Bushing: 1988-2000 Civic and 1993-’97 Del Sol, P/N 52385-SR3-000; 1997-2001 CR-V: P/N 52385-SR3-003.

Tool Information:

Trailing Arm Bushing Installation Set: T/N 07AAF-SK7A130.

Repair Procedure:

Note: Honda online service manual information is available only for vehicles 1990 and newer.

1. Remove the rear trailing arm. Refer to the suspension section of the appropriate service manual, or go online and enter keywords Rear Suspension, then select Suspension Arm Replacement from the list.

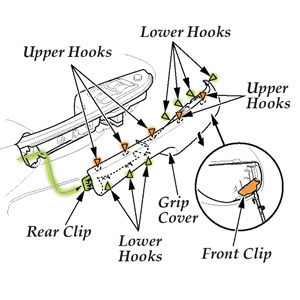

2. Mark the trailing arm at the arrow on the bottom of the bushing. See Fig. 1.

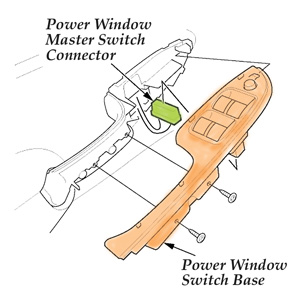

3. Place the arm on a hydraulic press, supported by the hub base, with the spindle facing up. See Fig. 2.

4. With the hub driver, press the old bushing out of the trailing arm.

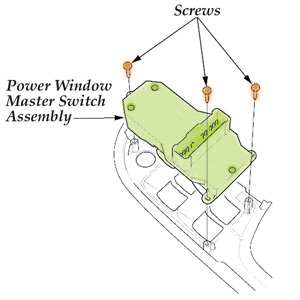

5. Install the new bushing with the short end toward the outside of the vehicle. Align the arrow with the mark you made on the trailing arm. See Fig. 3.

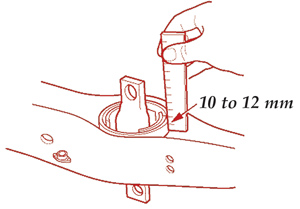

6. Press the new bushing into the trailing arm until its edge is 10 to 12 mm above the surface of the arm. See Fig. 4.

7. Reinstall the trailing arm.

8. If necessary, repeat steps 1 through 7 to install a new bushing in the other rear trailing arm.

9. Bleed the brake system. Refer to the brakes section of the appropriate service manual, or go online and enter keyword Bleed, then select Brake System Bleeding from the list.

10. Check the wheel alignment, and adjust it if necessary. Refer to the suspension section of the appropriate service manual, or online, enter keywords Wheel Alignment, then select Wheel Alignment – Rear Toe Inspection/Adjustment from the list.

Technical service bulletin courtesy of Mitchell 1.

For additional information, visit www.mitchell1.com.