Top quality was the utmost priority during the entire development stage. All parts went through rigorous testing, not only for aesthetics, but also for performance. Marcel builds no more than two engines a week.

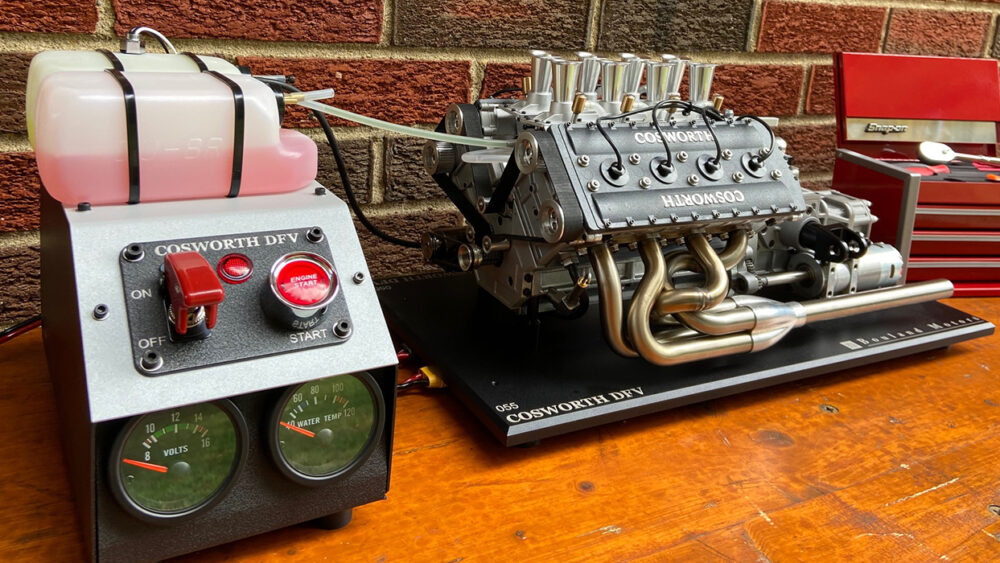

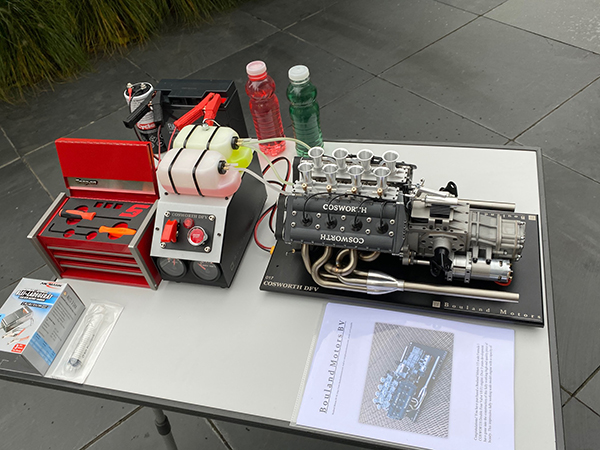

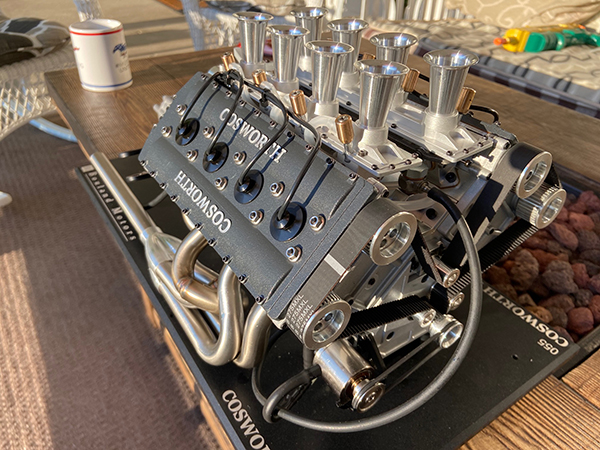

The 1:3 scale Cosworth engine has a .9448˝ (24mm) bore and a .8267˝ stroke (21mm). It weighs nearly 31 lbs., including its aluminum stand, and is 15˝ long by 9˝ wide by 7˝ high. The model engine runs on methanol with a 6% oil blend, is water-cooled, has an electric start, and features eight carburetors.

The transmission attached to the model is solely for looks, but Debeljak says they do offer a working out drive for those who want to build a running model. Before delivery, each engine is tested for about one hour to ensure proper break-in of the piston rings and liners. During this period, each carburetor is also fully adjusted for optimal performance.

Marcel’s capabilities allow this 1:3 scale model engine to emulate the real deal very closely. One of the few differences to the real engine are that the cams use a belt and pulleys instead of gears, due to strength. Gears would be too small and unable to handle the power. Otherwise, the 1:3 Cosworth emulates the real V8 engine even down to titanium valves.

The engine comes assembled, tested and tuned, and also includes an original mini Snap-on toolbox with tools and starter kit, which consists of a little fuel tank, tank for coolant, 12v power supply for the starter motor, temperature and battery voltage gauges, and a starter button. For a cool $12,000, one of these impressive engines can be yours.

According to Debeljak, the market for these mini motors are historians, race fans, car collectors, and people who like fine art to display in their home or garage. As of now, Marcel only builds the Cosworth engine model, but has considered an early Porsche engine as a next project.

To date, a total of 58 1:3 scale Cosworth engines have been sold worldwide since coming on the market two years ago. There are around 60 engines left. And, if you’re wondering if you can see and hear the engine run, the answer is yes, you can! Check out this video on YouTube.

This article is courtesy of Engine Builder.

For additional information on Bouland Motors USA, please visit: FB – facebook.com/Boulandmotorsusa. Instagram – instagram.com/bouland_motors_usa. Website – boulandmotorsusa.com