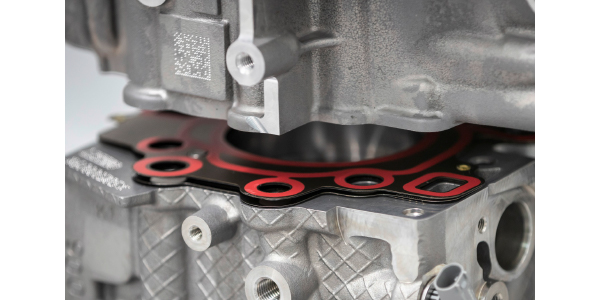

In 1970, Japanese gasket maker Ishikawa received the first patent for the multi-layer steel (MLS) head gasket. The first production vehicle to use an MLS gasket was a tiny Isuzu car in Japan.

This technology didn’t exactly burst onto the scene until 1991 when Ford used an Ishikawa gasket on its new 4.6L Modular V8. In the 1990s, the main selling point was that the engine did not require re-torque of the head bolts after running a while.

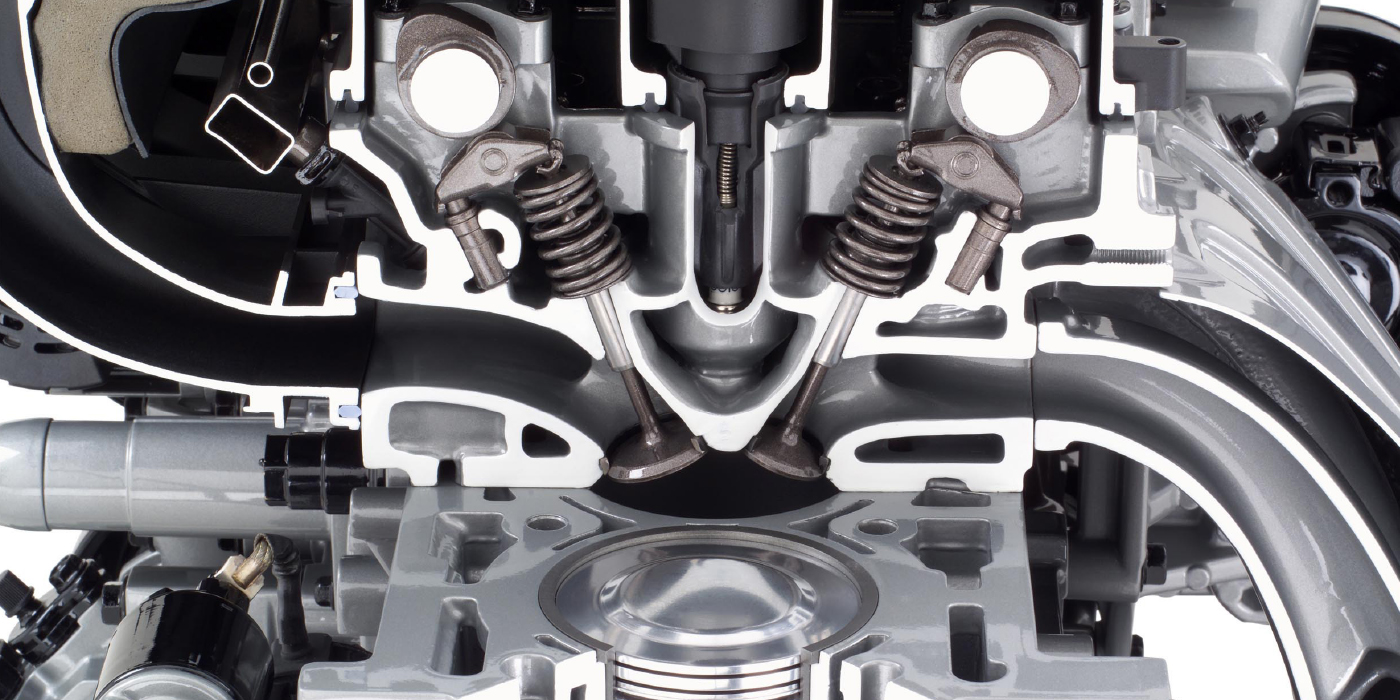

MLS head gaskets are made of multiple layers of embossed stainless steel. These embossments, when stacked in layers, create what is essentially a spring. It’s that spring that allows for recovery magnitudes higher than what a composite gasket is capable of.

Over the past 30 years, MLS head gaskets have become the gaskets of choice for OE service and the performance aftermarket. Many aftermarket gasket manufacturers have improved on the original design. ■