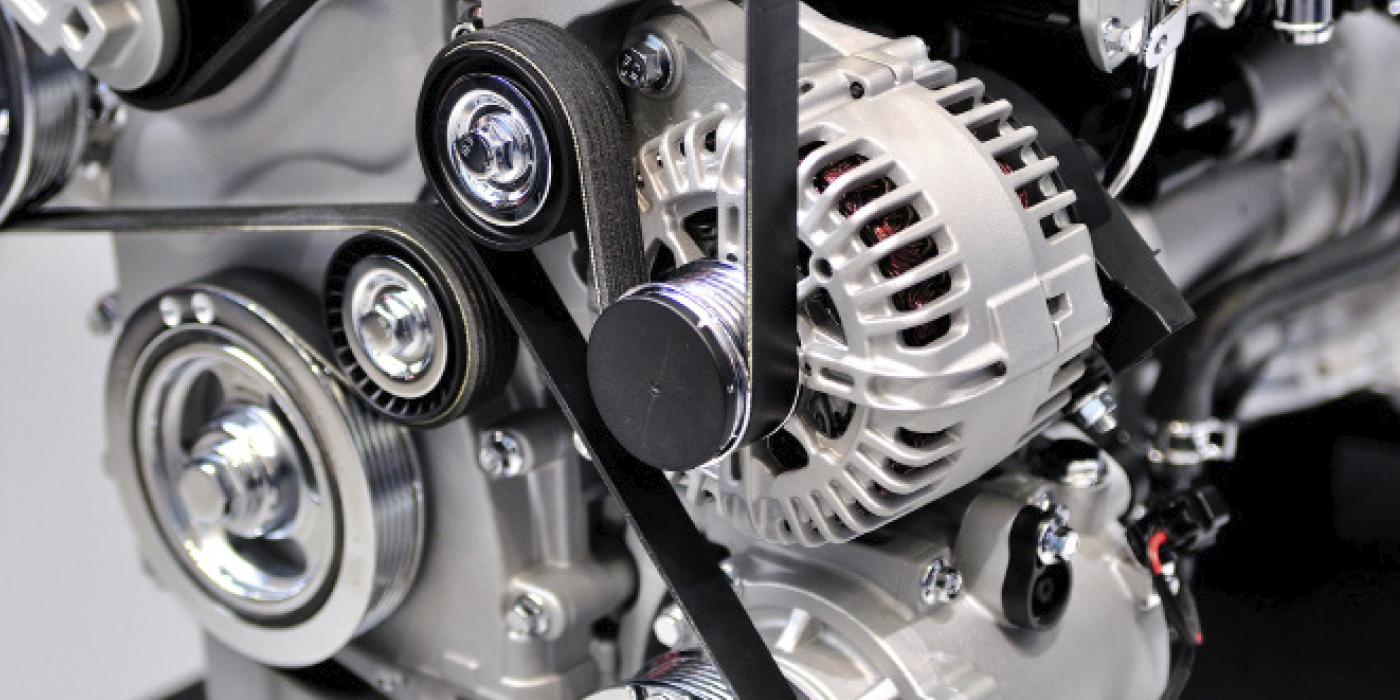

Alternator pulleys are not so simple anymore. Many late-model vehicles are equipped with special pulleys that are engineered to reduce NVH (noise, vibration and harshness) and extend the life of the alternator.

An Overrunning Alternator Pulley (OAP) has a one-way clutch mechanism inside the hub that allows the belt to turn the alternator in one direction, but allows the alternator to “free wheel” and spin at its own speed when the engine suddenly decelerates.

A good OAP pulley should lock up and turn the alternator rotor when it is turned one way, but release and free wheel when it is spun in the opposite direction. If the internal clutch mechanism is bad, the pulley may slip and fail to drive the alternator, or it may remain locked all the time — increasing noise, vibration and stress on the belt drive system.

Another type of special pulley is an Overrunning Alternator Decoupler (OAD). This type of pulley also has a one-way overrunning clutch inside the hub, as well as an internal torsion spring to further dampen vibrations in the belt drive system. The spring acts as a shock absorber to cushion the hub. This reduces noise at idle and low engine speeds, and helps dampen harmonic vibrations at higher speeds. If the clutch or spring inside the pulley has failed, the pulley may fail to drive the alternator, or it may create vibrations and noise.

How can you identify these types of alternator pulleys? OAP and OAD pulleys usually thread onto the alternator shaft. Solid pulleys typically slide onto the alternator shaft or are press-fit and held in place with a large bolt on the end of the shaft.

Some replacement alternators come with new pulleys already installed and some do not. If an alternator with an OAP or OAD pulley is being replaced, and the replacement unit does not have a pulley installed, or if it is a simple pulley and not the same type of OAP or OAD pulley, the original pulley can be removed from the old alternator and installed on the new unit — providing it is in good condition. However, on high-mileage vehicles, replacing the original OAP or OAD pulley with a new one is recommended to ensure trouble-free operation.

What happens if a replacement alternator does not have the same type of pulley as the original? It will turn the alternator, but it won’t offer any dampening or overrunning protection. The result will likely be noticeably higher NVH while driving.

INSTALLATION

Never pound on a pulley when you are installing it on a shaft. This can damage or distort the pulley and/or damage the shaft bearings. Use a pulley removal tool to remove a press-fit pulley, and a hydraulic press to install a press-fit pulley. Pressure should be applied only to the hub, never to the pulley flange.

Proper drive belt tension also is critical for any alternator pulley. Most late-model vehicles with serpentine belts use an automatic belt tensioner to maintain an even load on the belt. Proper tension requires a tensioner that rotates freely with good spring tension. Over time, the spring can weaken or break, causing a loss of tension that results in belt slippage, increased belt wear, reduced charging output and noise (typically belt squeal). The tensioner pivot bushing also can wear or stick.