Affected Models:

R55 (Cooper Clubman S) with N14 engine

R56 (Cooper S) with N14 engine

R57 (Cooper S Convertible) with N14 engine

*Vehicles produced up to Dec. 15, 2009

Condition:

The customer complains of loss of performance and turbocharger noise.

Cause:

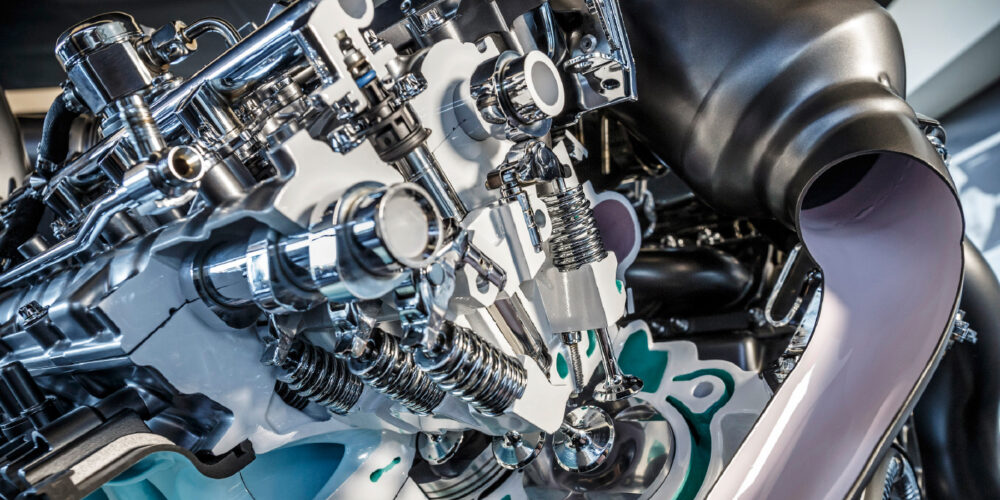

The turbocharger oil supply may be restricted, causing oil starvation and resulting in the seizing of the turbocharger assembly.

Repair Procedure:

Upon replacement of the turbocharger assembly, always remove and inspect the oil supply lines for blockage or restriction. Ensure that the lines are not collapsed or kinked. Replace the lines if a blockage or restriction is detected. Inspection of the oil supply lines will help avoid repeated failure of the turbocharger assembly. In addition, a protective cover (Part # 11657603484) should be installed on the supply line. If a restriction is detected in the oil supply line, the engine oil and oil filter should be replaced as part of the repair.

Courtesy of ALLDATA.