The Penray Companies Inc. has introduced a new year-round diesel fuel product for medium- and heavy-duty vehicles called Pow-R 365 5-in-1 Diesel Treatment. According to Penray, the product’s versatile blend of additives and conditioners improves fuel economy and engine performance in commercial and construction/agricultural operating environments in both summer and winter seasons.

The Penray Companies Inc. has introduced a new year-round diesel fuel product for medium- and heavy-duty vehicles called Pow-R 365 5-in-1 Diesel Treatment. According to Penray, the product’s versatile blend of additives and conditioners improves fuel economy and engine performance in commercial and construction/agricultural operating environments in both summer and winter seasons.

Pow-R 365 gets its name from the five benefits it provides on a year-round basis, which are:

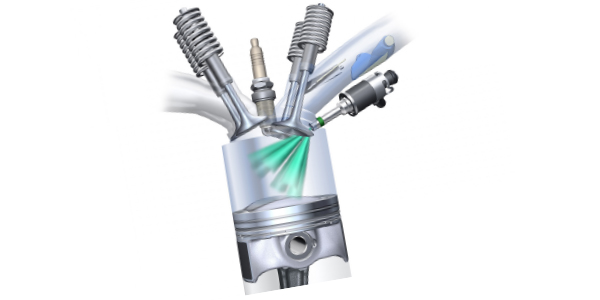

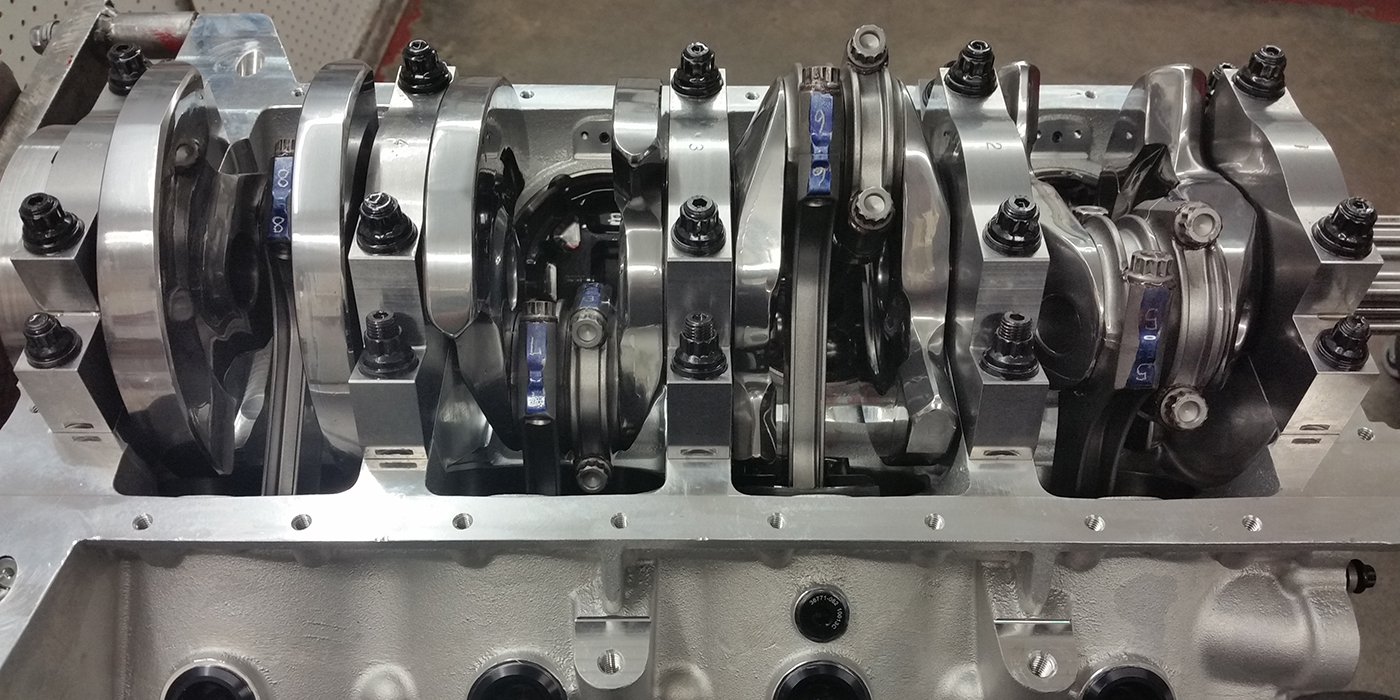

1. Increases fuel cetane rating by a full point, making for improved combustion.

2. Helps increase fuel economy, a key benefit given the ever-rising cost of diesel fuel.

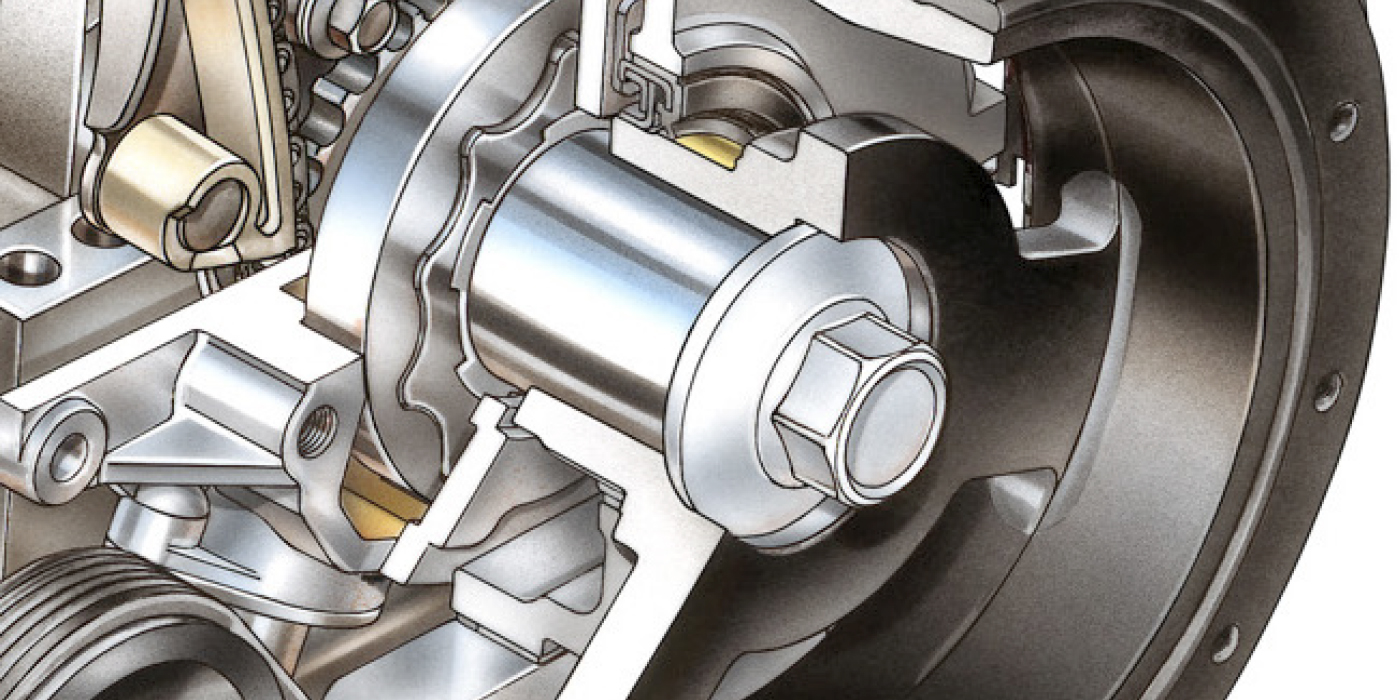

3. Protects vital fuel system components like fuel injectors from corrosion, which is particularly important since water is often found contaminating Ultra Low Sulfur Diesel fuel (ULSD) and bio-fuels.

4. Enhances lubricity, offering protection at key points of fuel system friction, like injectors and pumps.

5. Provides protection down to zero degrees F, preventing gelling that’s common in diesel fuels at lower ambient temperatures. In addition, it reduces the Cold Filter Plug Point (CFPP) by as much as 20 degrees F.

By promoting more complete combustion, Penray’s new Pow-R 365 can help reduce regenerations of the Diesel Particulate Filter (DPF), the company states. At the same time, this more complete combustion results in enhanced fuel economy. Sold in bottles of 64 fluid ounces, each bottle treats 250 gallons of diesel fuel, making it particularly economical, the company adds. Like other Penray products, Pow-R 365 Diesel Treatment was developed in Penray’s U.S. labs in Illinois. It also is manufactured and packaged in the U.S.

Sarah Cooper, product manager for Penray, emphasizes the versatility of this new addition to Penray’s offerings for the heavy-duty market. “Penray has long been known for high-quality, high-performance specialized diesel fuel additives. Pow-R 365 is a great addition to our lineup, encompassing the five most important fuel additive functions in a single product,” says Cooper. “Treating with this year-round product ensures your system is ready for all unexpected conditions from inclement weather to poor quality fuel.”

“We believe Pow-R 365 to be such a good product that we are backing it with a money back guarantee,” adds Cooper. “If a customer is unhappy with the product for any reason, we will provide a full refund. But of course we are so confident in this product that we expect full satisfaction by all who use it.”

Penray Pow-R 365 5 in 1 Diesel Fuel Additive is just one of the many chemical products that Penray offers for heavy-duty vehicles, including Class 6, 7 and 8 over-the-highway trucks, mobile off-highway vehicles, agricultural equipment, and marine applications. Information on all of Penray’s heavy-duty products can be found at www.penray.com/powerfleet.