When automotive technicians order parts for a repair job, they know they need the right part, and a quality part as well. So, it is just a common procedure of any repair job that technicians will inspect the new part to make sure it is a correct as well as a quality part without any visual or functional flaws that would lead to a poor repair job and a customer come back.

When automotive technicians order parts for a repair job, they know they need the right part, and a quality part as well. So, it is just a common procedure of any repair job that technicians will inspect the new part to make sure it is a correct as well as a quality part without any visual or functional flaws that would lead to a poor repair job and a customer come back.

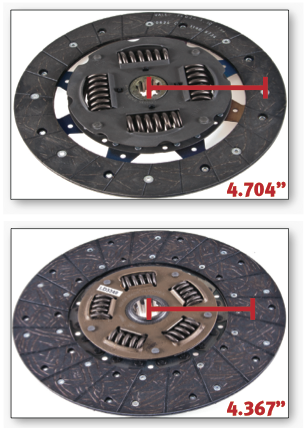

Many newer design clutch friction discs are designed with a thinner band of friction material than the original disc that came in the vehicle. The thinner band of material on the newer design may seem like a bad thing to some technicians as they compare the new and original parts that came out of the vehicle. Conventional thinking would be that more is better; more friction material will mean a stronger clutch.

Sometimes Less Is More

The active radius of a friction disc is defined as the distance from the center of the disc’s splined hub to the center of the friction material. So by using a thinner band of friction material on the disc, the active radius will be increased. The active radius can be thought of as a lever. The longer the lever the easier it is to move a given load.

The pictures illustrate how a thinner band of friction material will increase active radius and therefore the torque capacity of a clutch.

Tech Tip courtesy of Schaeffler Automotive Aftermarket.