Do you have a Mercedes-Benz in your bay with a no-start condition? Don’t feel alone, we’ve been there, and would like to share a few lessons we have learned over the years that can also help you expedite the diagnostic process.

1) We have experienced no-crank conditions on W140 models (S-Class from 1992-‘99) and W129 models (SL-Class from 1990-2001). Some of these vehicles will have bad ignition switches, but normal circuit 50 signal testing will almost always let you know if the switch is sending out the correct signal.

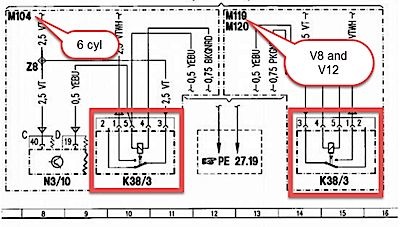

Here is the lesson: In 1997 and newer V8s, there is a starter lock-out relay (K38/3) that you may not expect to find. Note: check your wiring diagrams to be sure of M.Y. breaks. See Figure 1.

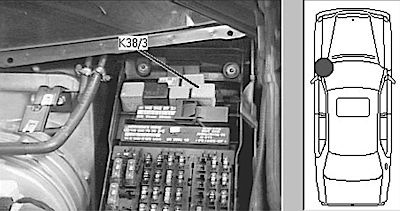

The relay is located in the rear of the front fuse box. In the early models (1992-‘95), the relay is located here behind the dash — “Passenger compartment, upper right side of dash, behind air bag.” Translation: Behind the passenger air bag (happy hunting!). See Figure 2.

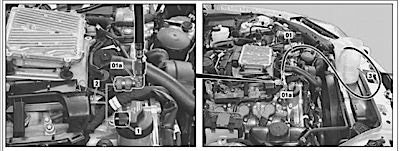

2) Some cars have two batteries, so be on the lookout. The W230 models (SL-Class) have a battery under the hood and a battery in the trunk. A dead or bad underhood battery will give you a no-start condition. (Some sources refer to it as the starter/alternator battery.) Don’t just replace the battery. Rather, be sure to perform a battery cut-off relay test. This relay (K57) will switch power to allow the starter battery to be charged. See Figure 3.

3) Keys! This is an often-overlooked source of no-starts since most techs assume that if the key turns, it must be good. Don’t assume, and as that old adage goes, you should know why.

You need the ability to check for drive authorization. We have seen keys that will turn, all the dash lights will come on, but the engine won’t crank. We have also seen keys that will turn, but there will be no dash lights on. Always ask your customer for a second key. If they don’t have one, do not continue testing without it. Yes, the keys are expensive ($250-$450), but everyone should have a spare for events like this.

If you don’t have a scanner that can check for drive authorization, you may not want to go any further.

4) There may not be any diagnostic codes set for EZS and EIS (electronic ignition switch) components. Testing starts with the basics, power and ground, and then a second key.

Once these are verified OK, look in Drive authorization for key recognition. If OK, test for circuit 50 output at the EIS. Newer cars are equipped with an EZL (electronic steering lock), which can prevent the engine from starting. You may see a steering lock fault code. If so, test per the instructions. See Figure 4.

5) What if the engines cranks over just fine? Common failures are the crankshaft position sensor and there may be a P0335 code. If you do have the code (pending or stored), and the sensor has not been replaced, now is the time to replace it.

No code? A quick scope check for the correct square wave pattern will let you know if it is bad.

Watch out for vehicles that stall but will restart after cool down. Also, watch for those that don’t start after a hot soak. The crankshaft position sensor could be at fault in these cases.

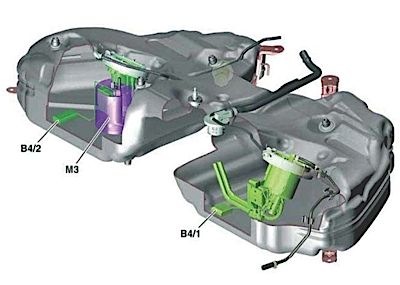

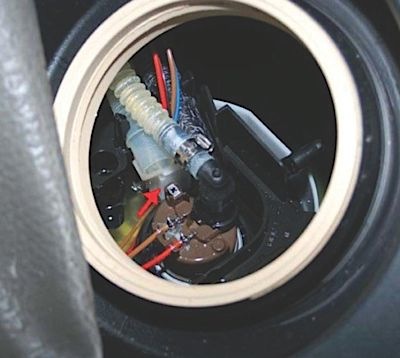

6) The next sources you should check are fuel pressure and fuel volume, as a bad fuel pump can also cause a no-start condition. See Figure 5.

There are several TSBs for fuel pumps, so be sure to look them up. We have seen the ME (engine control unit) not sending the correct signal to the fuel pumps. Get your wiring diagram out for testing.

Check for heat damage from a pump that’s drawing too many amps in vehicles equipped with a fuel pump in the SAM (signal acquisition module). Just replacing these pumps will result in a certain comeback.

Pop the lower rear seat cushion out to get access to the panels for the fuel pumps (see Figures 6, 7 and 8).

All images courtesy of ALLDATA.