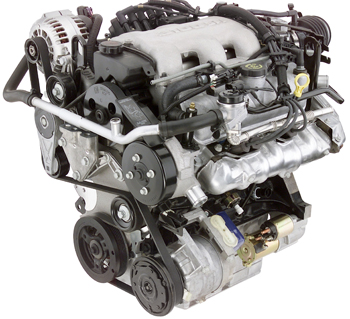

The General Motors 3.1L V6 engine enjoyed a long production run from 1988 through 2005.

The General Motors 3.1L V6 engine enjoyed a long production run from 1988 through 2005.

Over 10 million of these engines were built during this period. The engine itself went through continual evolution and improvement during its production life, including Gen II and Gen III versions, plus an “Enhanced 3100” version from 1999 to 2001.

The engine itself was based on the earlier 2.8L V6 that was first produced back in 1980. The 3.1L was eventually replaced with various versions of the 3.4L V6. Today, the 3.1L lives on in China where it is being made in various displacements (2.5L, 3.1L and 3.4L) for GM’s Chinese-built Buicks. The larger 3.4L version has been imported into the U.S. since 2005 to power the Chevy Equinox.

Over the years, GM has saved a bundle on manufacturing the 3.1L engine by using the production line tooling it originally developed for the 2.8L V6. By simply changing the bore diameter, the displacement of the same engine block could now be increased for more power and torque.

The narrow 60° angle of the V6 cylinder banks was chosen so the engine would more easily fit into front-wheel drive cars and minivans (though it has also been used in rear-wheel drive applications, too).

Most of these vehicles have aged to the point where they don’t have much resale or trade-in value. A real cream puff low-mileage mint condition car might fetch a couple thousand dollars on a used car lot.

But, many of these vehicles are so old that they are probably worth less than $1,000 — which makes it tough to justify spending a lot of money on repairs if major engine work is needed. Even so, many people are hanging onto their old cars longer than ever these days and are still putting money into repairs to keep them running. You might have a tough time selling a customer a rebuilt long block, but they might consider swapping in a used V6 as a less expensive alternative.

Except for the notorious leaky intake manifold gasket problem that has plagued many of these engines, the 3.1L V6 has had a reputation for being a long-lived reliable engine. Consequently, there are still a lot of these engines on the road and people are still spending money keeping them running. We’ll touch on some of the more likely repairs shortly.

Engine Notes

With one notable exception, all of the 60° V6 engines in GM’s 2.7/3.1/3.4L family have been conventional pushrod designs with two vales per cylinder. The one exception was the dual overhead cam (DOHC) “LQ1” version of the 3.4L engine produced from 1991 to 1997.

The 3.1L V6 utilizes a 3.50” bore with a 3.312” stroke crankshaft. The block has gone though half a dozen variants since its inception, with different mountings, sensor fittings and reinforcements for both FWD and RWD applications.

Some of the engines (notably 1990-’95 FWD minivans) had cast iron heads, while most of the later engines came with aluminum heads. The Gen III version of the engine (L82 built from 1993 to 1999, and the later LG8 VIN code J engines) added a composite roller cam and used a number of slightly different cylinder heads. Roller rockers were also used on most 1995-’99 3.1L engines.

If you’re swapping in a used engine for a customer, interchangeability will depend on the make and model year. The major differences to watch out for would be the A/C compressor and starter mounting bolt holes, and sensor mountings.

The 1988-’92 engines did not use a cam position sensor, some of the 1993-’94 engines had cam sensors and some did not, while all of the 1995 and later engines had cam sensors. Early versions of the RWD engine and FWD minivans used a distributor ignition system while all of the FWD car applications had waste-spark distributorless ignition systems.

The only “problem” block in the 3.1L V6 engine family to watch out for was the one used in some 1988-’90 FWD cars and minivans, casting #10065459. This particular casting tended to develop cracks near the center cylinders.

Applications for the 3.1L engine have included:

1994-2005 Buick Century

1989-1996 Buick Regal

1994-1998 Buick Skylark

1990-1996 Chevrolet Beretta

1990-1992 Chevrolet Camaro

1990-1994 Chevrolet Cavalier

1990 Chevrolet Celebrity

1990-1996 Chevrolet Corsica

1990-1995 Chevrolet Lumina APV

1991-1992 Isuzu Rodeo

1994-1998 Oldsmobile Achieva

1989-1997 Oldsmobile Cutlass Supreme

1994-1996 Oldsmobile Cutlass Ciera

1990-1995 Oldsmobile Silhouette

1988-1991 Pontiac 6000 (STE & LE, but primarily for STE)

1990-1992 Pontiac Firebird

1994-1998 Pontiac Grand Am

1989-2003 Pontiac Grand Prix

1991-1994 Pontiac Sunbird

1990-1995 Pontiac Trans Sport

Six Common Problems of the 3.1L

#1 Leaky Intake Manifold Gaskets. This is the most common problem on these engines. Some have blamed the problem on GM’s Dex-Cool antifreeze, but the real problem has been the intake manifold gaskets.

The original equipment gaskets have a plastic carrier and soft sealing beads around the coolant and intake ports. Over time, the plastic carrier and seals soften and deform, causing the gasket to lose its seal.

Coolant then starts to leak down into the lifter galley and crankcase. Eventually, the loss of coolant causes the engine to overheat, which may cause additional damage such as a cracked cylinder head or crushed head gasket. The leakage problem can occur in as little as 60,000 miles on some engines. The higher the mileage, the more likely the intake manifold gaskets are leaking coolant.

Coolant leakage can be diagnosed by checking the oil dipstick (if the oil looks milky or foamy it probably has coolant in it) or by pressure-testing the cooling system. If an internal coolant leak is indicated, the fix is to pull the intake manifold and replace both intake manifold gaskets. Several aftermarket gaskets offer design and material improvements over the OEM gasket to provide a longer lasting trouble-free seal.

Replacing the old intake manifold bolts with new ones is also recommended.

#2 DIS Ignition Problems. The waste-spark DIS ignition system on the 3.1L is similar to that used on other GM V6 engines. It has been a fairly reliable ignition system, but at high mileage, it can develop problems like any other ignition system.

#2 DIS Ignition Problems. The waste-spark DIS ignition system on the 3.1L is similar to that used on other GM V6 engines. It has been a fairly reliable ignition system, but at high mileage, it can develop problems like any other ignition system.

Ignition misfire can be caused by worn or fouled spark plugs, bad plug wires, weak coils or faults in the ignition control module. No starts are most often due to faults in the crank sensor circuits (there are two on most engines). In some cases, a no start or intermittent loss of spark can be caused by wiring that is chafing near the rear exhaust manifold.

The DIS system has three coils that share paired cylinders (1-4, 6-3 and 2-5). If any of the individual coils fail, it will cause a misfire in the two paired cylinders it supplies with high voltage. Random misfires, on the other hand, are more often due to a lean fuel condition caused by intake manifold vacuum leaks, dirty fuel injectors or a leaky EGR valve.

If you suspect a bad coil, one trick is to swap two adjacent coils to see if the misfire moves to the other two cylinders. If there’s no change, the fault may be poor contact between the two spade terminals under the coil and the ignition module, or a fault within the ignition module control circuitry. You can also check the secondary resistance of each coil with an ohmmeter. A good coil should read 5,000-7,000 ohms. Also check the underside of each coil for cracks or carbon tracks that would tell you high voltage is leaking from the coil.

If the engine cranks but won’t start and there’s no spark from any of the coils, check the ignition control module supply voltage and ground connections. If both are okay, check to see that both crank sensors are producing a signal. Chances are the problem will be a bad crank sensor, but it could also be a wiring fault between the crank sensors and ignition module.

#3 MAF Sensor Problems. The fuel injection system on the 3.1L engines used a mass airflow (MAF) sensor to measure airflow. The PCM also looks at inputs from the throttle position sensor (TPS), engine speed and temperature to calculate airflow and how much fuel is needed for the correct fuel mixture.

#3 MAF Sensor Problems. The fuel injection system on the 3.1L engines used a mass airflow (MAF) sensor to measure airflow. The PCM also looks at inputs from the throttle position sensor (TPS), engine speed and temperature to calculate airflow and how much fuel is needed for the correct fuel mixture.

The little heat-sensing wires in the MAF sensor can become coated with dirt, carbon or fuel vapor varnish over time, causing the sensor to misread airflow. A dirty MAF sensor typically under-reports airflow, creating a lean condition in the cylinders. The O2 sensors in the exhaust will pick up the lean mixture, causing the PCM to command a richer mixture to compensate — which may make the fuel mixture too rich.

Symptoms of a dirty MAF sensor may include rich or lean codes, fuel trim codes, poor fuel economy, rough idle or even black smoke (carbon) in the exhaust. If there’s a serious fault in the MAF sensor circuit itself, you may find a P0101, P0102 or P0103 code.

Cleaning the sensor with aerosol electronics cleaner (nothing else!) will often fix the problem and restore normal operation. If the cleaning doesn’t solve the problem, the MAF sensor may be bad. A simple check here is to hook up a DVOM to the MAF sensor’s output signal wire and look for a change in the frequency signal as the engine is revved from idle.

No output at all, no change in the signal or an erratic change would all tell you there’s a problem with the sensor. Check the MAF sensor’s input voltage and ground wires before replacing the sensor because the fault might be in the wiring, not the sensor.

#4 EGR Problems. The 3.1L engines use a variety of different electronic EGR valves. The common problem here is a buildup of carbon under the EGR valve that prevents the valve from fully closing when EGR isn’t needed.

A leaky EGR valve will act just like a vacuum leak, causing a lean fuel mixture, rough idle and misfiring. You may find misfire codes or various EGR related codes when you do your diagnosis.

A dirty EGR valve can be cleaned with carbon remover. The EGR port in the manifold should also be cleaned to make sure there are no obstructions. A blocked EGR port can cause spark knock and detonation when the engine is under load. Install a new gasket under the EGR valve when it goes back on the engine.

#5 Dirty Fuel Injectors. Any high mileage engine can develop dirty injectors, especially if the vehicle owner has been using the cheapest gas he or she can buy that contains minimal amounts of detergent. GM recommends using a Top Tier gasoline that contains extra levels of fuel system cleaner so deposits don’t build up in the injectors.

Symptoms of dirty injectors include lean misfire, random misfire, hesitation when accelerating, a rough idle, hard starts and reduced performance.

One way to diagnose dirty injectors is to do an injector balance test. The test shows how much the fuel pressure drops after each injector is energized one by one for a fixed amount of time. The pressure drop itself doesn’t tell you anything (unless an injector is completely clogged, in which case it would show zero pressure drop). What you want to look for is how much the pressure drop varies from one injector to another. If you see more than 3 psi difference between the highest and lowest readings, the injectors are dirty and need to be cleaned.

GM recommends using a 10% concentration of its Top Cleaner product to flush the injectors. GM warns against using any injector cleaner that contains methanol as this may damage components in the fuel system.

High-mileage fuel injectors on these engines can also fail electronically due to internal shorting, which may be due to using gasoline that contains more than 10% ethanol.

#6. Intermittent Electronic Control Faults. GM tech bulletin 09-06-03-004D says various fault codes and intermittent driveability problems and other faults may be caused by corrosion and fretting in various control module wiring harness connectors.

Vibration and corrosion can take a toll on the wiring in any vehicle after many years of driving. What happens is that the little pins inside the connectors may lose electrical contact either intermittently or permanently as a result of vibration, rubbing and/or corrosion.

This obviously upsets the operation of whatever module the wiring is connected to. The fix, says GM, is to unplug the wiring harness connectors, inspect and clean the pins and terminals as needed, then reassemble using a small amount of dielectric grease (don’t overdo the grease or it may hydrolock the pin cavities and prevent the pins from making good electrical contact).

If the problem goes away, the fault has been fixed (at least temporarily). If the problem is still there, it may be an intermittent wiring fault or an internal control module problem.