In 2017, 33% of new vehicles sold, including cars, SUVs and pickup trucks, had turbocharged engines, according to data source IHS. The majority of these vehicles are now out of warranty and driven by your customers. The turbocharger adds another layer to the diagnostic onion.

Turbocharger systems use multiple sensors to monitor turbocharger performance. Boost pressure sensors, MAP sensors and throttle position sensors work together to make sure the desired pressures match actual pressures.

If the ECM sees a large enough variance between the boost measured and the boost requested, a code will be set. The code could have the wastegate, diverter valve or sensor listed in the description – but in most cases, the part contained in the code is never the one that has failed. The source of the over or under boost condition must be addressed first.

Turbocharger Tools

Diagnosing an under-boost condition on a modern engine requires a scan tool that can graph multiple data PIDs from the data stream. The two most important parameters to look at are the desired boost pressure and the actual boost pressure during a test drive.

The first thing to see is if the boost reaches the desired level. If the boost is low, it is a sign there might be a leak in the system. If the boost is slow to build, it could be a sign there might be an issue with the wastegate or bypass leaking.

The next parameter in the data stream to look at is the position or duty cycle or requested position of the bypass or wastegate valve compared to the boost pressure. Look for a change in the requested position or duty cycle and changes in boost pressure. If boost pressure does not change, it could indicate a mechanical issue.

Your regular smoke machine used to diagnose EVAP problems might not work because boost levels are, in some cases, five times higher than EVAP testing requires. But there are high-pressure smoke machines that can detect leaks in turbocharger systems.

Using a scope and pressure transducers can give you additional insights into the condition of the turbocharger and engine. With a multi-channel scope, you can graph boost and voltages being sent to actuators to determine if a bypass or wastegate is working. The pressure transducers can also be used to detect leaks that might only occur when boost pressures exceed specific pressures.

Leaks

Working on a turbocharged engine requires the skills of both a plumber and technician. One of the most common problems with turbocharged engines is leaks.

Under the hood of a turbocharged car or truck is the piping that carries the pressurized air from the turbocharger to the intake manifold. Between components are intercoolers, hoses and pipes.

Intercoolers are typically found before the radiator and condenser. If the vehicle hits an object that hits an intercooler it can cause a leak. Inspecting the intercooler for damage should be one of the first items on the list if boost is down.

Turbocharger Damage

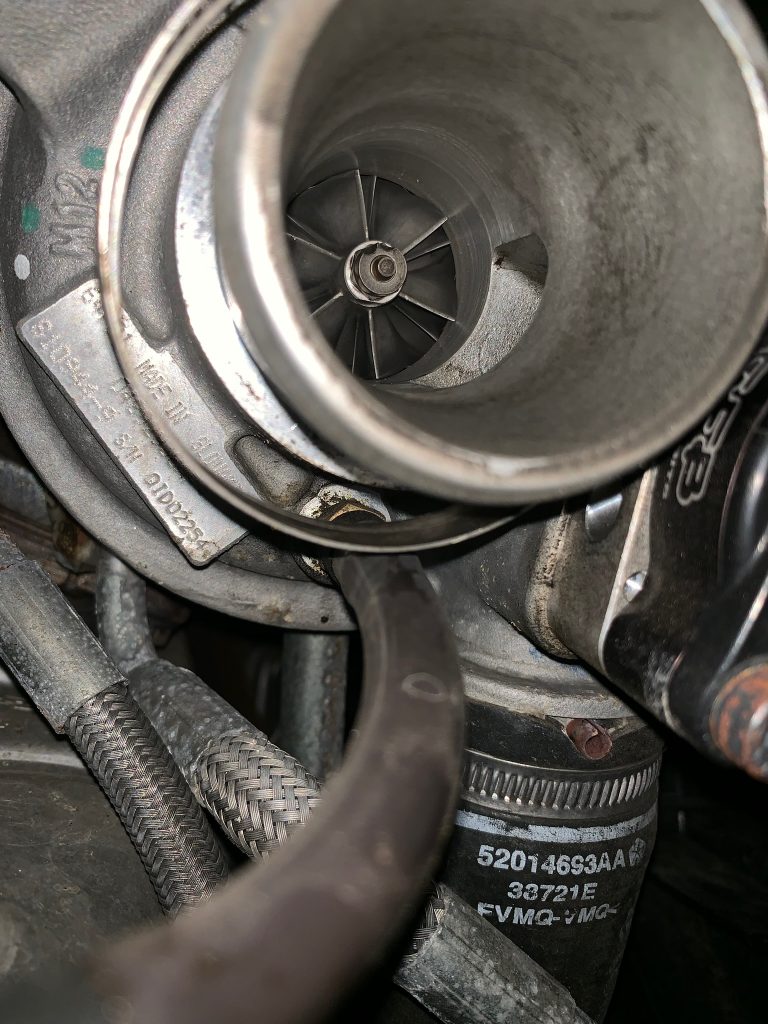

The compressor wheel driven by the exhaust turbine is a precise component. If there is play in the shaft or bearings, the relationship of the compressor wheel to the housing is changed, and the turbocharger produces less boost.

The most likely cause of turbocharger compressor wheel damage is a damaged or restricted air filter. Another cause of vane damage is the mishandling of the old filter when it is removed from the housing. Debris can be dislodged from the old filter and fall into the air filter housing, causing damage when ingested.

Controlling Boost

Most modern turbochargers use an internal bypass valve that recycles the excess boost into the intake system before the compressor. A solenoid or a vacuum diaphragm can actuate the valve. If the bypass valve has a weak spring or a torn diaphragm, the boost can be significantly reduced. Some vehicles and scan tools will allow you to actuate the bypass valve. When the valve is open at idle, it will not be a significant difference – but under load, the loss of boost will be noticeable. The bypass valve also prevents the surging of the air when the throttle valve is shut. The surge of air can stall the compressor wheel and cause stress on the shaft.

The wastegate on the exhaust side of the turbocharger regulates the speed of the exhaust turbine. When the wastegate opens, it routes exhaust gases around the spinning turbine to the exhaust manifold or downpipe. This causes the turbine to slow down and boost to be reduced. If the valve is stuck open, the turbine will not spool up and boost will not be generated. If the valve is stuck shut, there can be rapid changes in compressor speed. Excessive boost might be created, and the surging of air can occur on the compressor side of the turbocharger.

As with the internal bypass valve, some scan tools will allow you to actuate the wastegate.

Most wastegates have a preload specification for the rod and actuator. If the preload is not correctly set, it can cause the wastegate to leak or not open at the correct time. Preload setting procedures typically involve closing the wastegate valve and changing the length of the rod, so the diaphragm is slightly depressed.

Another commonly missed cause of under boost conditions are restrictions in the catalytic converters and exhaust system. If the exhaust system is restricted, it can prevent the turbine from spooling up.