Amazingly, up to one-third of the heat energy produced inside an engine’s combustion chambers ends up as waste heat that goes into the block. This heat must be eliminated, otherwise the engine will overheat and self-destruct.

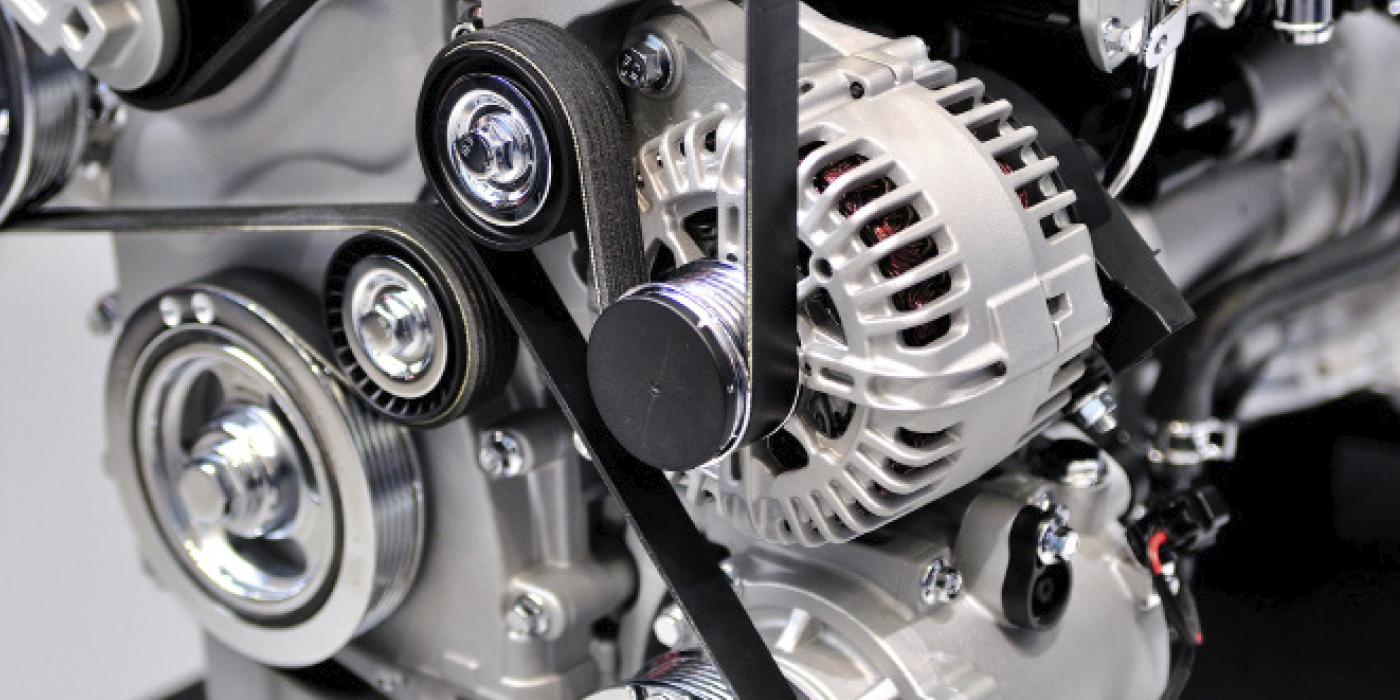

The water pump keeps coolant circulating between the engine and radiator to get rid of the heat. The pump is usually belt-driven and turns continuously while the engine is running. Most pumps are mounted on the front of the engine and are driven by a V-belt or serpentine belt. Some water pumps are mounted under the timing belt cover on overhead cam (OHC) engines and are driven by the timing belt. A few are mounted on the back of the engine or head and are driven by the camshaft.

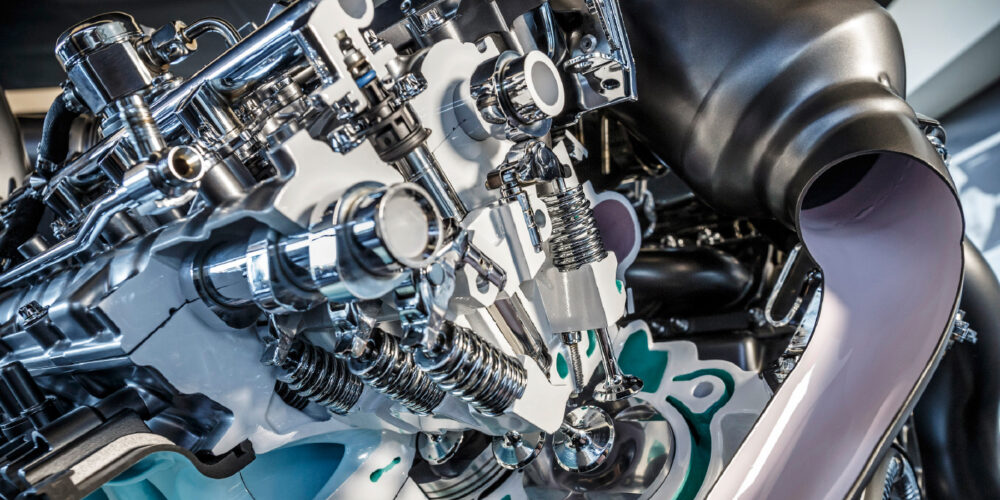

The water pump housing itself is usually made of cast iron, aluminum or stamped steel. Inside the housing is a paddle-style impeller mounted on a shaft supported by a bearing and seal assembly. The bearing assembly has two sets of bearings (ball or needle style) with a seal to prevent coolant from leaking out of the pump. The back of the pump housing may have a cover or bolt directly to the block, requiring a separate gasket.

PUMP FUNCTION

On most engines, the pump pulls coolant in through the lower radiator hose and pushes it into the block. The coolant then flows up through the heads and returns to the radiator through the thermostat housing and upper radiator hose. On some vehicles, a “reverse flow” system is used. In this style of system, the water pump routes coolant into the head(s) first, then the coolant circulates through the block before returning to the radiator.

On most engines, the pump pulls coolant in through the lower radiator hose and pushes it into the block. The coolant then flows up through the heads and returns to the radiator through the thermostat housing and upper radiator hose. On some vehicles, a “reverse flow” system is used. In this style of system, the water pump routes coolant into the head(s) first, then the coolant circulates through the block before returning to the radiator.

The water pump also circulates coolant through the heater. The water pump typically has a second outlet that is connected by a hose to the heater core. The coolant then flows back to the engine or pump through a return hose. Some pumps also have an additional outlet port for a “bypass” connection that allows coolant to circulate through the block when the thermostat is closed.

Water pumps work hard, typically pumping several hundred gallons of coolant per hour at highway speeds. Because of the continuous load on the water pump, failures are not uncommon. The first symptom is usually significant leakage at the pump weep hole. More than a few drops of coolant coming out of the weep hole usually means trouble. Other symptoms include bearing noise (rumbling, chirping or growling), loss of coolant (through the leaky shaft seal), overheating (from coolant loss or separation of the impeller from its shaft) and fan wobble.

PUMP PROBLEMS

One way to spot a water pump with bad shaft bearings is to check pulley or fan play with the engine off. The pulley or fan should not wobble or show any visible play when it’s tugged by hand. Suspected seal leaks can be diagnosed by pressure-testing the cooling system.

If a water pump has reached the end of the road and needs to be replaced, you can offer your customer a new or remanufactured pump. Reman pumps typically include a new bearing and seal assembly but reuse the original impeller (unless it was damaged), shaft and housing.

PUMP REPLACEMENT

Because of the variety in OEM pump configurations, make sure the replacement pump has the same mounting configuration, bolt locations and hose connections as the original. Also compare pump heights as these may vary depending on the dimensions of the timing cover or other belt-driven engine accessories.

When a water pump is replaced, the cooling system should always be drained, flushed and refilled with a fresh mixture of antifreeze and water to restore proper cooling performance and corrosion protection. Just draining the radiator can leave as much as 50% of the old coolant in the engine block.

RELATED SERVICES

Belts and hoses should also be carefully inspected, and replaced if any are found to be in less than perfect condition. Hoses that are brittle, aged, cracked, bulging or chaffed must be replaced. New clamps should also be recommended. Belts that are frayed, cracked or glazed also need to be replaced. On OHC engines that use the timing belt to drive the water pump, check the mileage on the original timing belt. If the belt has been in service more than the OEM-recommended replacement interval (60,000 miles on older vehicles, and up to 100,000 miles on newer ones), the timing belt should also be replaced. This will save the labor of having to do the job twice because the timing belt usually has to be removed to install the pump.

If the engine has overheated because of a pump failure or loss of coolant, you should also recommend replacing the thermostat. Overheating can damage the wax-sensing element inside the thermostat, preventing it from opening properly at the right temperature.

Another component that may need to be replaced is the fan clutch (if the vehicle uses one). The lifespan of the fan clutch and water pump are about the same, so if one has failed many experts recommend replacing both components at the same time to reduce the risk of future cooling problems. Other items you may need to purchase for the job include a gasket sealer or RTV silicone sealer, and thread sealer for any water pump bolts that extend into open water jackets in the engine block (to prevent leaks).

Maintaining Fluids in Import Vehicles

by Kit Johnson

Picking the proper lubricant for your customers’ import car will depend on the application. For example, serious track racers with large ponies under the hood will want heavy-duty, high-performance racing lubricants designed specifically to stand up under the stress. For the average high-performance import car, quality products will provide good functionality and durability for almost any application.

Regardless of what the OEMs say, I believe the 3,000-mile service is still a very viable benchmark for an oil and filter change and vehicle inspection for any import. Carbon, grit and raw fuel contaminates engine oil, so regular oil drain and refills keep internal engine parts clean and free from gumming up. It’s also a good opportunity to check for leaks, potential problems and component wear.

Other fluid recommendations include:

Transmission, power steering and brake fluids should also be flushed regularly (30,000- to 60,000-mile service intervals) to avoid excessive wear and component failure. As a rule of thumb, I recommend changing those fluids when they start to show discoloration.

Automatic transmission fluid should be light red in color and flushed every 30,000 miles. If the transmission fluid turns a dark brown, black or smells burnt, it’s a sure sign that it needs to be flushed.

Healthy power steering fluid will be clear or red in color. A buzzing sound when the steering wheel is turned at low speeds indicates that the power steering fluid is likely low.

Brake fluid is hygroscopic, meaning it absorbs water to prevent rust from damaging the brake system and moisture from turning to steam, which produces brake fade during extreme braking conditions. Healthy brake fluid should be clear or have a light brown tint. As it becomes saturated with water, it will begin to turn black. The darker the brake fluid, the greater the need to flush the system.

Coolant is another often-overlooked fluid. A good 50/50 mixture of distilled water and coolant that is flushed every 30,000 miles or three years (whichever comes first) will prevent electrolysis and internal corrosion from occurring.

— Johnson is president of J4 Auto-motive, Inc., East Helena, MT, and the 2007 national NAPA Technician of the Year.