Rust Never Sleeps

Rust Never Sleeps

A customer complaint consisted of an early model Pontiac Montana that was running rough with a Service Engine Soon lamp illuminated.

Following an initial inspection, Diagnostic Trouble Code P0300 was found to have been set.

The technician continued his diagnosis and repair on the Pontiac fuel system with a look at the fuel injectors.

Examining the vehicle, it was found that the engine misfire could be traced to a number of fuel injectors.

After removing the suspect injectors that were found to be contaminated (Figure 1), the technician took a fuel sample from the vehicle fuel rail. However, he didn’t notice any visual signs of contamination.

After allowing the fuel sample to sit for the weekend, a contaminate began to form in the bottom of the container.

After allowing the fuel sample to sit for the weekend, a contaminate began to form in the bottom of the container.

The contaminate found in the fuel was determined to be water.

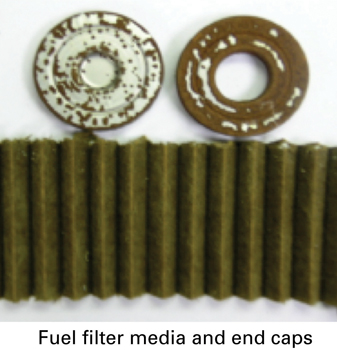

The technician removed fuel filter and found it to be unrestricted. Though the end caps were rusted, the media in the element was relatively clean and free of contamination.

See Figure 2.

Next, the technician removed the fuel tank and the modular reservoir assembly (MRA) and found the tank to be clean.

He also noticed that the external strainer on the MRA was discolored, but clean.

The MRA appeared to be the original one (no history of replacement and build date of MRA and vehicle are consistent).

The MRA appeared to be the original one (no history of replacement and build date of MRA and vehicle are consistent).

The bucket strainer also appeared to be discolored, but clean.

Upon inspection, rust was found in the MRA bucket.

See Figure 3.

The fuel pump strainer also was contaminated with rust.

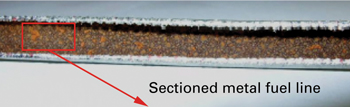

The technician found that the metal fuel lines were rusted internally.

The diagnosis was that the vehicle had water in the fuel tank, which was likely pumped into the tank via a contaminated fuel supply.

The water passing through the fuel lines caused the inside of the metal lines to rust (Figure 4), and the rust that flaked off found it’s way into the injectors, fuel pressure regulator and MRA bucket.

The rust created in fuel lines between the filter and fuel rail was then caught in the fuel injectors and fuel pressure regulator.

The rust created in the metal return line was captured in the MRA bucket, since the return line dumps fuel directly into the bucket of the MRA, and not into the tank.

The rust created in the metal return line was captured in the MRA bucket, since the return line dumps fuel directly into the bucket of the MRA, and not into the tank.

In essence, the fuel filter and MRA bucket strainer had no opportunity to capture that rust since it was being formed after the filtering devices.

The takeaway here is that anytime rust is found in the injectors and MRA bucket, and the vehicle uses metal fuel lines, they should be inspected for rust and replaced as necessary.

Without replacing the fuel lines, a repeat fuel component failures, and an irate customer, will occur.

Courtesy of Delphi.