Engine “knock” may be heard on an applied vehicle just above engine idle speed (800-1,100 rpm) with the engine under a slight load. The noise cannot be detected over 1,100 rpm.

Applied Vehicles:

• 1999-2002 Frontier (D22) with VG33E; not supercharged.

• 2000-’02 Xterra (D22) with VG33E; not supercharged.

The cause may be a normal pulsating noise coming from the EVAP purge solenoid valve and piping (in the engine compartment) transferring into the passenger cabin. However, use the following procedure to reduce the noise.

Service Procedure:

1. Start and run the engine for at least one minute.

2. Use CONSULT-II to view the status of the “Closed Throttle Position Switch” (CTPS).

3. Set the Parking Brake, then perform the following;

• For vehicles with an automatic transmission, with your foot on the brake, place the A/T gear selector in “D.”

• For vehicles with a manual transmission, depress the clutch and select any gear.

4. While viewing CTPS status, open the throttle just enough to change the CTPS status from “On” to “Off.”

Note: This will allow the EVAP purge volume control solenoid valve to begin operating.

5. Listen closely for a slight “knocking” noise. If “knocking” noise is heard;

a. Put the transmission in “neutral” (M/T) or “park” (A/T).

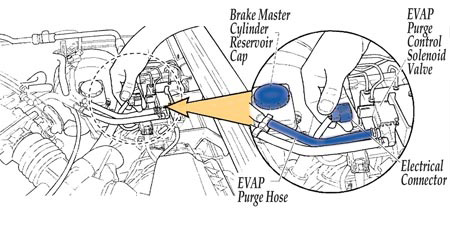

b. Disconnect the electrical connector to the EVAP purge volume control solenoid valve. See Fig. 1.

c. Listen again for the “knocking” noise by repeating steps 3, 4 and 5.

• If the “knocking” noise is still heard, this service bulletin does not apply. Consult the appropriate service manual for further diagnosis.

• If “knocking” noise is not heard, shut off the engine and proceed to step 6.

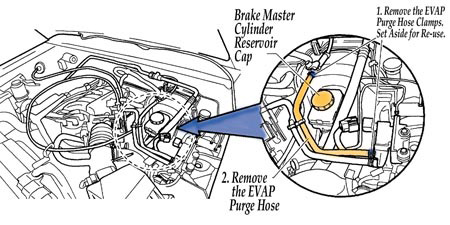

6. Remove the hose clamps from the EVAP purge hose. See Fig. 2.

7. Remove the EVAP purge hose. See Fig. 2.

Note: Set aside the two purge hose clamps for use in step 8.

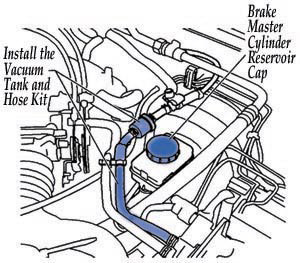

8. Install a vacuum tank and hose kit (P/N 14958-5S625). See Fig. 3.

Note: Use the hose clamps set aside in step 7 to secure the replacement parts.

9. Reconnect the electrical connector to the EVAP purge volume control solenoid valve. See Fig. 1.

10. Repeat steps 3, 4 and 5 to verify the slight “knocking” noise is gone.

Technical service bulletin courtesy of Mitchell 1.

For additional information, visit www.mitchell1.com.