By Eric Seifert

Automotive Technical Editor

Chris used his 2001 Chevy Silverado to pick up some sod for a friend. The rear of his truck has been squeaking ever since taking that bumpy road to the sod farm. Chris was relieved to learn that there was a simple cure for the annoying squeak.

During normal operation, certain vehicles may exhibit a squeaking noise that can be traced to the rear leaf springs. While this noise is an operating characteristic of leaf springs, the frequency and severity of this noise will be affected by the roads on which the vehicle is driven. The noise may be due to debris getting between the leaf springs.

To correct this condition, lubricate the rear leaf springs with GM P/N 12345996 (in Canada, use P/N 10953501) grease, using the following procedure.

Applicable Vehicles

• 1999-2007 Chevrolet Silverado (Classic)

• 1999-2007 GMC Sierra (Classic)

Repair Procedure

(Review safety procedures in the ALLDATA system before beginning)

Important: It has been found that the application of grease to the rear leaf springs does a better job of preventing the noise from re-occurring than replacement of the spring.

1. Raise the vehicle on a frame lift-type hoist.

2. Inspect the springs for damage. If none is found, proceed to the next step.

3. Pressure wash the rear leaf springs to remove as much dirt and grit as possible.

4. Dry the springs with compressed air.

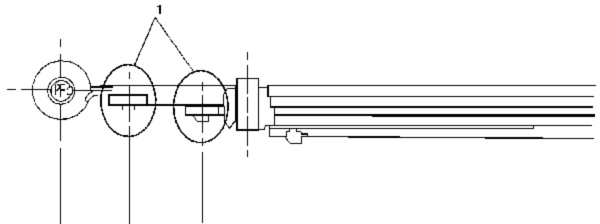

5. Apply a liberal amount of grease, GM P/N 12345996 (in Canada, use P/N 10953501), under the front and rear tip inserts for the #2 and #3 leaves, on top of the tip inserts, and in between the #1 and #2, and #2 and #3 leaves, as indicated. A screwdriver can be used to gently pry up the tip insert; however, a rag around the screwdriver must be used to prevent damage to the spring. Use a flat-bladed tool, such as a gasket scraper to properly distribute the grease.

6. Lower the vehicle to the ground and test drive to verify the repair.

Inform the customer that this will offer relief, but it is by no means a lifetime repair. Periodic cleaning and grease re-application may be necessary throughout the life of the vehicle.

For 1500 Series (1/2 ton) models only: On vehicles built prior to October 2004, if the above procedure does not correct this noise, it could be caused by an incorrectly dimensioned splay clip (the band holding the ends of the leafs together) that interferes with the leaf springs. A 5 mm (0.197 in) wider splay clip was introduced in early 2005 model year to provide additional clearance. To correct this concern, replace the rear leaf spring assembly.

Written by ALLDATA Technical Editor, Eric Seifert. Eric is an ASE certified Master Technician and Engine Machinist. He is a graduate of the De Anza College Automotive Technology Program, with 20 years of independent shop and parts store experience.

For additional information, visit www.alldata.com.