This article will document the infamous P0171 code – Lean Condition. A fuel system lean condition can be broken down into three subsections, namely, fuel pump performance, fuel quality and injectors. Keep in mind this is only a starting point, but it is a good place to start.

The fuel pump assembly should be checked for pressure, volume and amperage. And it is very important today that fuel quality be checked, as it is possible for a customer to pump in E85 fuel in error.

The last item that I am always concerned with is testing the injectors, which should pass an electrical test as well as have mechanical integrity. The question is how does one do this effectively for today’s engine families?

It is clear based on previous knowledge that testing injectors with a labscope while viewing voltage and current waveforms is a very effective way of finding poor electrical characteristics. The final analysis comes with the following realities: injectors can be clogged, leaking or possibly installed on the wrong engine family. If injectors are installed on the wrong engine family, you will witness incorrect flow rates, which can be somewhat difficult to isolate.

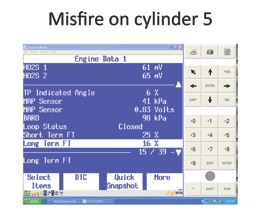

Our subject vehicle for this Pulling Codes case is a 2004 Pontiac Grand Prix with a 3.8L supercharged engine. There were a total of five codes stored in the PCM memory. The first code was P0128 – Engine Coolant Temperature below thermostat regulation; this code set due to low coolant level. The second and third codes were P0131 and P0137 – Low Voltage Code for Oxygen Sensors. Even though the upstream and downstream sensors were replaced, the codes were still present. The fourth code that was set was a P0171 – Lean Condition, and a review of the post oxygen sensor implied that the vehicle was truly running lean. The last and final code was P0300-Random Misfire. A misfire was created on cylinder number 5 (randomly chosen) to see how the vehicle responded. It was interesting to note that the oxygen sensor’s voltage went very low and stayed low, which was the opposite of what I expected to see. See Photo 1.

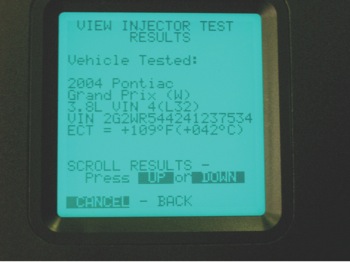

I then checked fuel pressure, volume and amperage. The fuel pump appeared to be working as designed. I proceeded to check fuel quality, finding that the alcohol content was within normal operating parameters. My final test was to verify the proper flow rate of the fuel injectors. I used a tool called the active fuel injector tester. This tester was designed for GM products, and a complete testing database is built into the unit. This tester will also test Duramax diesel and direct fuel injection injectors.

The active fuel injector tester allows one to test the flow rate of the injectors using the engine as the test bench. If you’re interested in learning more about this tool, see the sidebar below or you can go to http://gmspecialservicetools.spx.com/Documents/GM09-91A.pdf and download the document for the complete story.

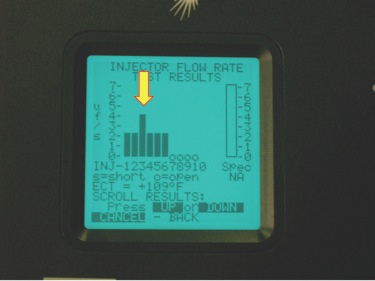

Let us now begin our evaluation. The tester is attached to the vehicle and some automated tests are performed. Photos 2 and 3 show the test results per a screen-by-screen play of the events.

Photo 3 shows that there is a problem with injector number 3. It has a different flow rate than the other injectors – it’s almost double the flow rate. The technician I was working with (a friend at a local shop) then looked at me and indicated that injector number 3 must be leaking and should be replaced. It was also noted that upon further inspection that the injector for cylinder 3 was a gray-colored injector while the other five injectors were black in color. See Photos 4 and 5.

It was quite interesting how my friend looked at me when the test was completed. It was as if it were a Sherlock Holmes movie, and my friend felt that this case study was quite elementary.

But like Holmes, I stated it was quite the contrary, we have before us one rich injector or five lean ones. When the order was placed for an injector, the normal color was gray; the black injectors were incorrectly installed on this engine. The supercharged 3.8L engine uses the gray-colored injectors; the normally aspirated 3.8L uses the black injectors. This explained the lean condition noted on the scan data when a single cylinder misfire occurred.

This Pulling Codes case is now closed. If you would like to offer any comments on this, e-mail me at [email protected].

Sidebar:

Active Fuel Injector Tester Technical Summary

The active fuel injector tester (AFIT) measures fuel injectors on-vehicle using pressure drop as specified in OEM diagnostic procedures.

Each injector on the vehicle is compared to a known-flow reference injector to produce accurate results.

• The AFIT corrects for variations in temperature, fuel system pressure and fuel viscosity.

It is a completely automated test routine.

• The AFIT prepares and stabilizes fuel rail.

• It pulses each injector and automatically begins pressure drop measurements.

• Each injector test begins and ends at precisely the same fuel rail pressures.

• The AFIT records and stores each pressure drop time in its memory.

• The Standard Injector in the AFIT Fuel Management Unit is a benchmark and tested several times before each engine injector to establish a reference for each test.

• Determines flow rate of each vehicle injector and pinpoints any faulty injectors.

Courtesy of SPX.