Deactivation Lifter Issues

The experts at Melling have noticed an increase in the issues surrounding the replacement of deactivation lifters in GM LS engines with Active Fuel Management (AFM). After installing new lifters, the original issue may not have been corrected. Most lifters returned for analysis are found to be good, with most lifter faults being caused by oil pressure issues or control issues.

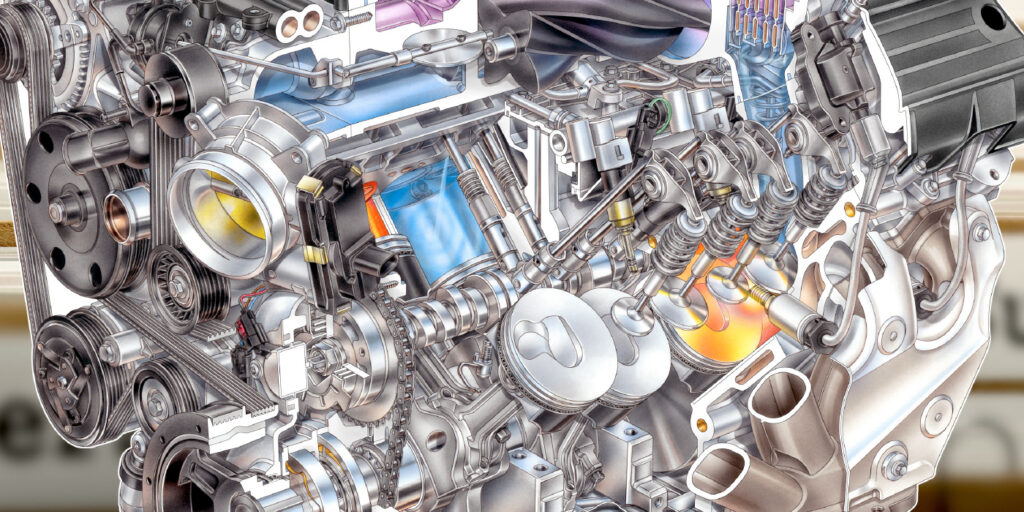

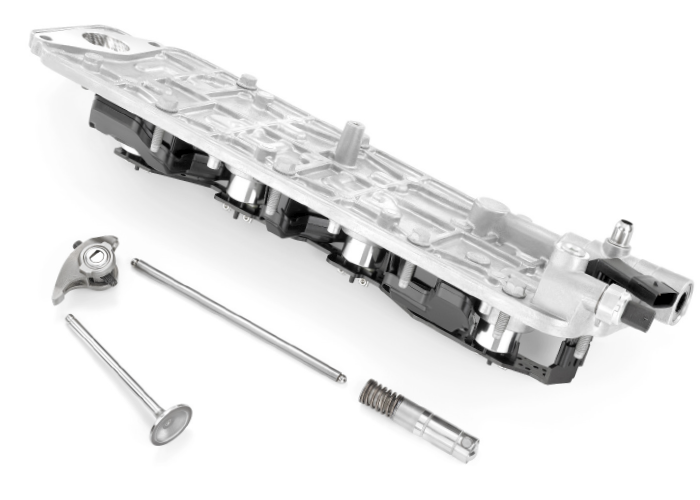

The AFM activation and deactivation are controlled by the Valve Lifter Oil Manifold or VLOM. The VLOM consists of four electronically operated solenoids and is bolted to the top of the engine block beneath the intake manifold assembly. Its job is to direct the flow of pressurized engine oil to the active fuel management intake and exhaust valve lifters.

The VLOM applies pressurized oil to the AFM lifters when cylinder deactivation is requested and shuts off that supply of oil to reactivate those cylinders. Cylinder activation and deactivation are both supposed to occur on the base circle of the cam lobe, making the transition from four- to eight- cylinder mode unnoticeable to the driver.

To control contamination, a small replaceable oil filter is located in the VLOM inlet oil passageway. The AFM oil pressure relief valve regulates the oil supplied to the VLOM and is located in the oil pan near the oil filter housing. The AFM system has an operating range from 27 psi to 66 psi of oil pressure. At higher engine speeds, the high side of this operating range is controlled by the AFM oil pressure relief valve. At low engine speeds, the low side of the operating range will depend on the engine’s ability to produce oil pressure using the flow of oil from the oil pump.

The AFM lifter bores in these engines have a spec of 0.843-0.844, and the deactivation lifters require 22 psi of pressure to release the locking pins. Taking these two things into consideration, a lifter bore that is even slightly worn could bleed off enough oil pressure to prevent the lifter from unlocking.

In addition, it has been reported that it is common to find the VLOM oil filter plugged and needing replacement on high-mileage engines with misfire fault codes. Melling has received AFM DEAC lifters back for warranty claims where the lifter has been stuck compressed.

This condition can be caused by the VLOM commanding activation or deactivation at the wrong point in the cam’s rotation, either in the ramp or at the lobe peak.

Any time an engine has failed AFM lifters, the lifter guides must be replaced, the lifter bores must be measured, and the VLOM must also be tested for proper operation or replaced. Additionally, the VLOM oil filter must also be replaced.

Courtesy of Melling, www.melling.com