In the next few months, you will be hearing a lot about E-15 summer-blend fuels making their way to gas pumps across the country. E-15 uses more ethanol in its blend to reduce our dependence on fossil fuels. No matter your political view, you must wonder what this means for engines.

E-15 has 15 percent ethanol. Most parts of the country have used E10 for more than a decade. Ethanol is a biofuel made from corn or other forms of biomass that is fermented. The process turns the starch into sugars that are fermented into ethanol.

The problem with ethanol is how it reacts to water in the air and in the tank. Ethanol can mix with water, while gasoline and water do not mix. Ethanol and gasoline can mix, but if the water concentration in the ethanol is too great, it can separate the ethanol and water from the gasoline. This is called phase separation. If the phase separation occurs inside the gas tank, the ethanol and water mix falls to the bottom of the tank, resulting in the pump bathing in this corrosive mixture. The phase separation issue might only be an issue with vehicles that sit for long periods or have EVAP issues.

Phase separation can also occur under conditions where the fuel tank is open to the outside air. On carbureted engines, phase separation can occur in the bowls. It is typically seen as blue or white crystals. Copper and bronze do not stand up well to corrosion in the first place. Since copper and bronze are used in electric fuel pumps and the coils in the injectors, corrosion can be an issue. For a carbureted vehicle, the blended mixture can react with floats, jets and even the pot metals and aluminum.

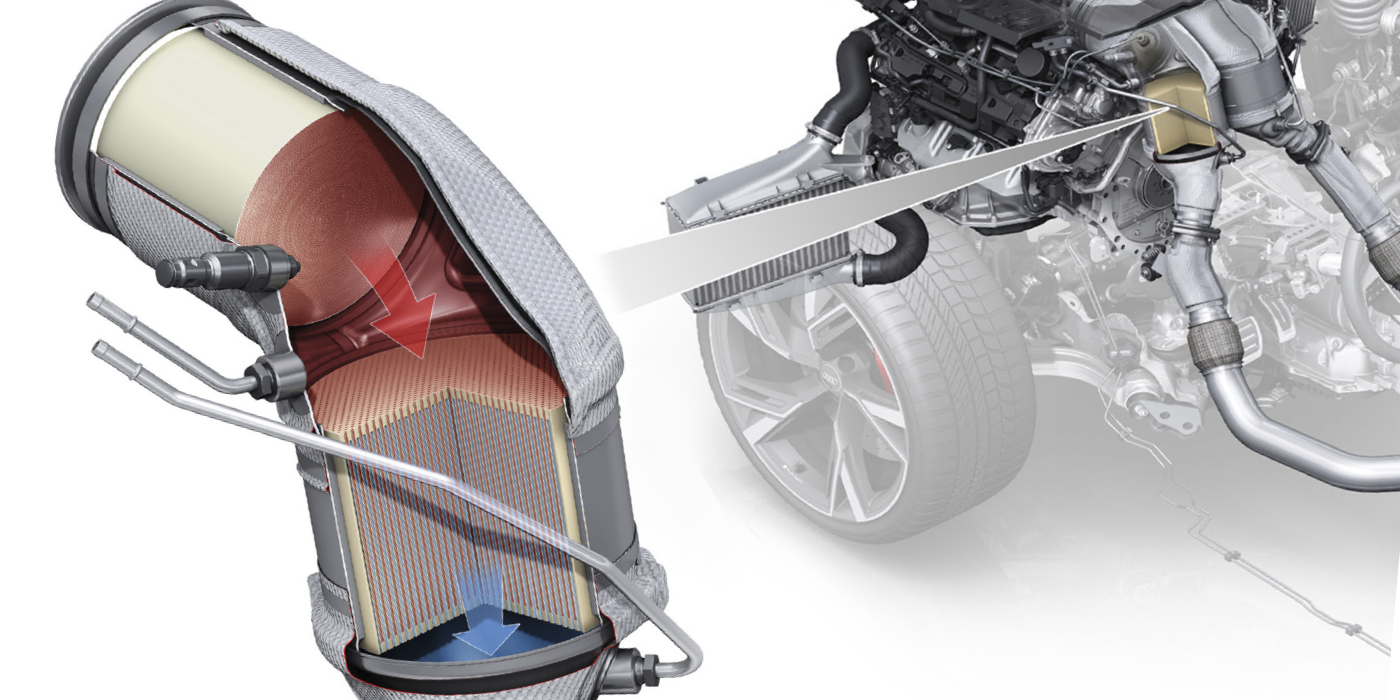

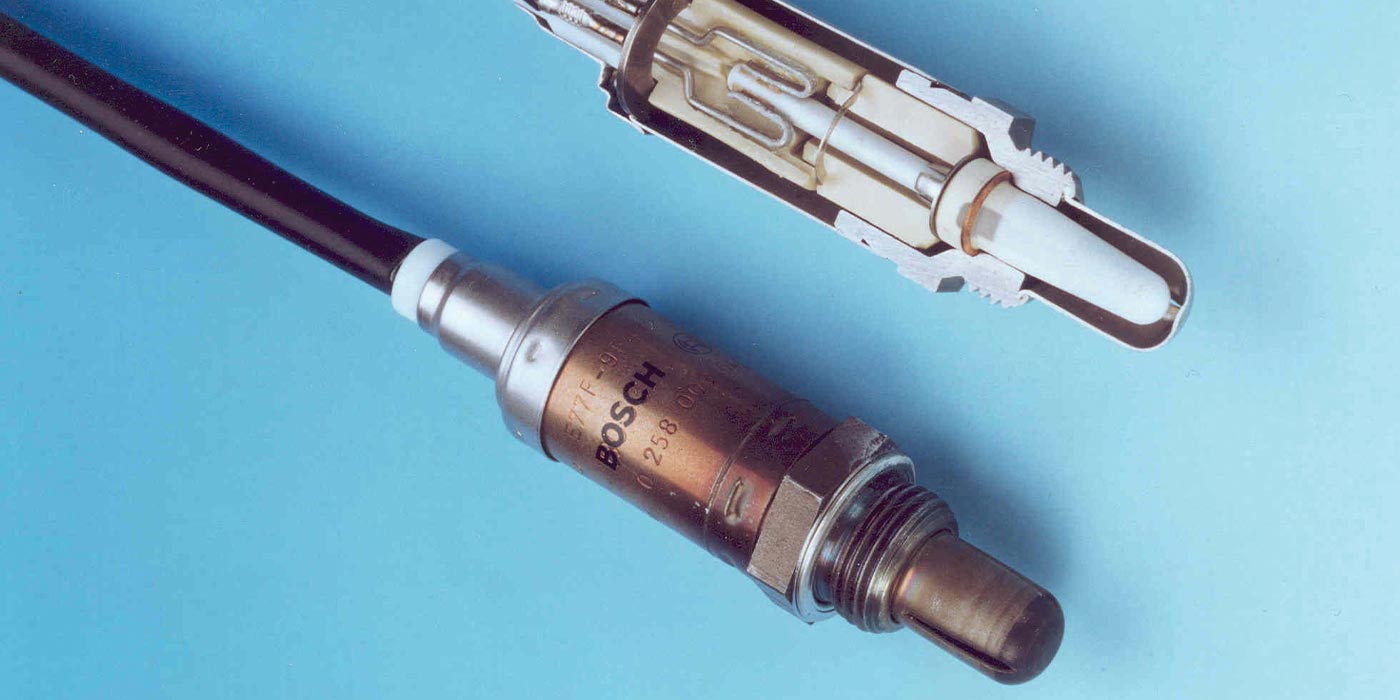

The reality is that most drivers don’t have to worry. Since the 2001 model year, most OEMs have engineered parts and programming to handle E-10 and E-15. If the vehicle is older than 2001, there might be compatibility issues with E-15. However, most engines will see the change in ethanol concentration as changes in the ignition timing and maybe changes to the long-term fuel trims due to oxygen sensor readings.

Fuel Pumps

E-15 can cause issues for fuel pumps that might be near the end of their life. However, if a replacement fuel pump manufacturer has cut corners in the manufacturing of an in-tank pump, E-15 can limit the life of the pump.

High-quality pump manufacturers have changed the materials for the plastic section of fuel pump modules. Nylon is the material of choice, but there are several formulations of nylon that stand up better to ethanol and gasoline. The wrong material can become brittle and even swell over time.

Ethanol and water can cause premature brush and commutator wear and corrosion of commutator brush wires. Some fuel pumps use carbon materials or alloys for the commutator pads to combat this wear. This eliminates oxidation and high electrical erosion.

Some fuel pump manufacturers also nickel-plate the carbon brush wire strands to prevent corrosion. In addition, ethanol-compatible materials prevent the swelling of non-metallic components.

Some manufacturers take it one step further by coating the pump’s armature to prevent the windings from coming in contact with fuel.

Fuel Hose

There are several theories about ethanol and fuel hoses. In theory, corrosive ethanol can damage materials, but modern hoses, made of materials like neoprene, are resistant to chemicals. If you do have to replace a fuel hose, read the side of the hose that starts with the letters SAE.

SAE has more than 16 active and inactive J30 standards for fuel and oil hoses. If you look at the side of a fuel, oil or emissions hose you will see the letters “SAE” followed by the number 30 (some will have a J first). Next in the sequence will be the letter “R” followed by a number. The number after the “R” refers to the section of the SAE performance standards.

The test criteria measure permeation, chemical resistance, construction, temperature range and kink resistance. The higher the standards go, the more criteria that must be met. “R” numbers do not determine the pressure rating for the hose. Hose manufacturers typically print on the hose that the hose is intended for use on fuel-injection systems. Also, you should check with the hose manufacturer to see if it is compatible with fuels like E85 or biodiesel. If a hose doesn’t have an SAE J30 standard on the side, don’t install it in a fuel system. SAE J30R12 includes low-permeation fuel feed and return hoses.

Some fuel hoses will also have a California Air Resources Board (CARB) number for the hose. This certification means that it has met the requirement for permeation. This means the hose prevents fuel from passing through the hose layers.

Spark Plugs

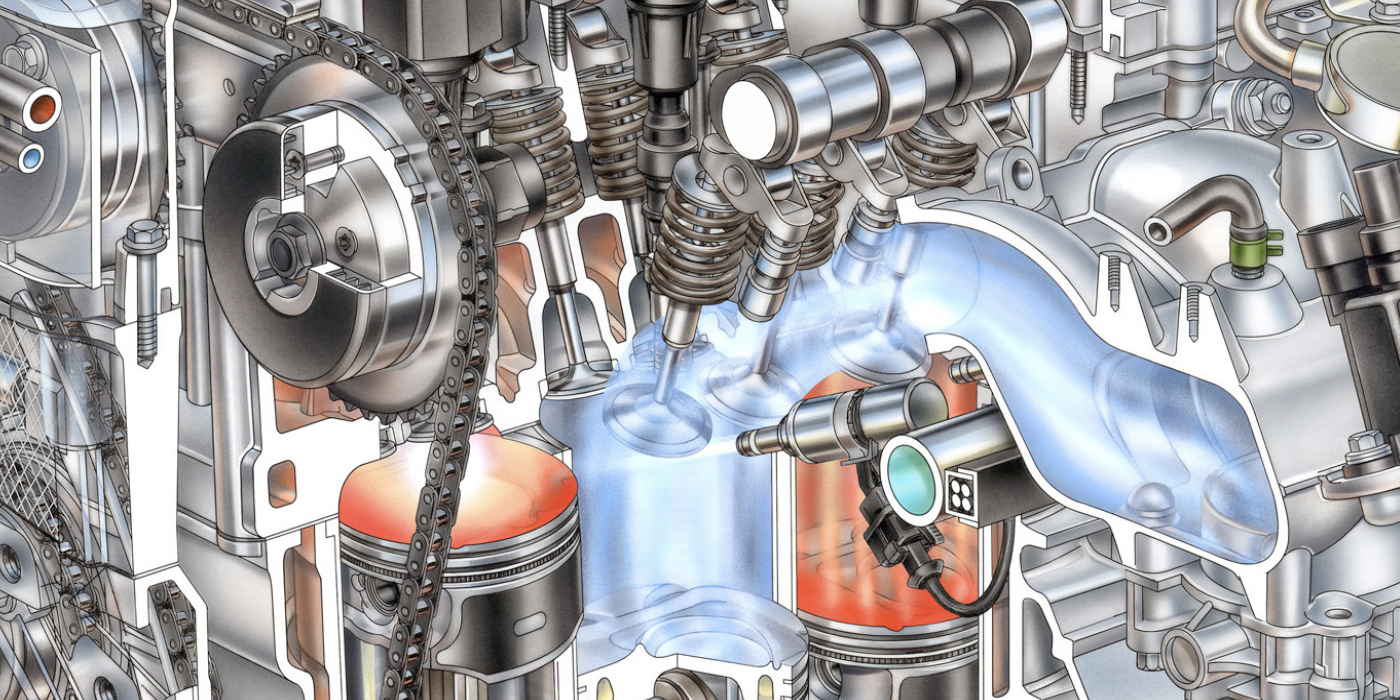

There are no unique spark plug recommendations for vehicles using the E-10, E-15 or E-85 Ethanol blends. Most vehicles have no modifications to their fuel or ignition systems, and therefore, they should be serviced as if they were running on gasoline only.

The only exception is when a factory gasoline-fueled engine has been converted to E-85 to support modifications to increase power output. In these engines, the spark plug should be one to two heat ranges colder, depending on the level of modification.

No matter the fuel blends or percentage of ethanol, a worn-out spark plug will have problems igniting the fuel inside the combustion chamber. This is why you need to look up the recommended replacement interval for the customer’s vehicle and replace them before they become a problem.

Why is ethanol getting a bad reputation? In my opinion, it is caused by older vehicles and lawnmowers. Whether it is E-10 or E-15, if it sits in a fuel tank for an extended period, it will experience phase separation. If it is a classic car or lawn tractor that sits all winter, there will be a problem when owners try to start them in April or May.

When they remove the tank or bowls of the carburetor, they will see the crust left behind from the evaporated fuels. They curse the gas station gods and tell everyone they know the evils of ethanol. The reality is, for vehicles made after 2001, it is not a problem if they are driven.